In the depths of water treatment technology lies an elegant solution that’s both simple and ingenious: bubbles. Not just any bubbles, but meticulously engineered micro-bubbles that are transforming how we think about membrane filtration. Swirltex has harnessed these tiny air pockets to create a membrane system that tackles one of the industry’s most persistent challenges – fouling. Their patented technology creates a turbulent, bubble-enhanced flow that keeps membranes clean while processing even the most challenging wastewaters. As water scarcity intensifies and regulations tighten, this Canadian innovation is positioning itself as a game-changer in the water treatment landscape.

with 🎙️ Peter Christou, President & Founder at Swirltex

Take-home message (in 2 long sentences 😅):

Swirltex revolutionizes the tubular membrane game by injecting air-liquid mixtures through their proprietary hydraulic system, creating a swirling vortex that prevents membrane fouling while doubling traditional flux rates. Their special sauce isn’t reinventing membrane materials but rather reimagining flow dynamics, allowing them to tackle notoriously difficult wastewaters in food & beverage, mining, and oil & gas industries that conventional membrane technologies have historically failed to handle effectively.

In this episode, you’ll learn:

🌊 How the SWX tubular membrane technology creates a step-change in performance by revolutionizing hydraulics rather than changing membrane materials

💼 Why food and beverage, mining, and oil & gas industries became strategic focus areas for SWX despite their operational differences

🔄 What makes the recurring revenue business model through membrane skid sales more attractive than full system integration or pure membrane sales

🌐 How partnerships with OEMs and strategic geographic expansion fit into SWX’s 30% annual growth plan through 2030

💰 If the current fundraising strategy aligns with SWX’s commercialization timeline and how it positions the company for acquisition opportunities

Let’s get into it!

The Bubble Breakthrough

At the heart of Swirltex’s revolutionary approach lies an elegant yet powerful innovation that harnesses the unique properties of bubbles to transform membrane filtration. The technology introduces carefully controlled air bubbles into the wastewater stream, creating a dynamic spiral flow pattern that fundamentally changes how particles interact with membrane surfaces.

The key breakthrough comes from how these microbubbles influence the fluid dynamics within the membrane system. As wastewater enters the membrane tubes, injected air creates a rotating spiral flow that generates strong centrifugal forces. These forces push heavier contaminants toward the tube walls while allowing cleaner water to flow through the membrane pores. The bubbles also create localized turbulence that continuously scours membrane surfaces, dramatically reducing fouling issues that plague conventional systems.

What truly sets this technology apart is its ability to separate contaminants based on density rather than size alone. Traditional membrane systems rely solely on pore size to filter particles, but Swirltex’s bubble-enhanced approach adds an entirely new dimension to the separation process. The spiral flow pattern can effectively remove oils, suspended solids, and other challenging contaminants that would typically cause rapid membrane fouling.

This innovative mechanism allows the system to operate at lower pressures while maintaining high throughput rates. The reduced operating pressure translates directly to lower energy consumption – typically 30-50% less than conventional membrane systems. Additionally, the continuous scouring action of the bubbles extends membrane life and reduces chemical cleaning requirements, further improving the economics of water treatment and reuse.

The implications of this breakthrough extend far beyond just technical performance. By fundamentally rethinking membrane operation through the strategic use of air bubbles, Swirltex has created a more sustainable and cost-effective approach to water treatment that could help make water reuse viable across a broader range of applications and industries.

Market Pain Points and Solutions

The wastewater treatment industry faces several critical challenges that impact operational efficiency and economic viability. Membrane fouling remains one of the most significant hurdles, causing decreased treatment capacity, increased energy consumption, and frequent cleaning requirements that drive up costs. Traditional membrane systems struggle with high-solids wastewater streams, where suspended particles quickly accumulate on membrane surfaces and clog pore structures.

Operational expenses pose another major pain point, particularly in energy-intensive treatment processes. Standard membrane systems require substantial pressure to force water through fouled membranes, leading to excessive power consumption. Additionally, the chemical cleaning agents needed to restore membrane performance add significant costs while potentially degrading membrane materials over time.

Treatment efficiency suffers greatly when dealing with variable influent qualities. Conventional membrane technologies often fail to adapt to fluctuating waste streams, resulting in inconsistent treatment results and compliance risks. Industrial facilities particularly struggle with this challenge, as production changes can dramatically alter wastewater characteristics.

The bubble-enhanced membrane system addresses these pain points through its innovative approach to solids management. By creating a boundary layer of micro-bubbles at the membrane surface, the technology prevents fouling particles from adhering while simultaneously scouring existing buildup. This self-cleaning mechanism significantly reduces maintenance requirements and extends membrane life.

The system’s enhanced flux rates enable treatment of challenging waste streams with lower operating pressures, resulting in energy savings of up to 50% compared to conventional systems. The technology’s ability to handle varying solids content without performance degradation provides operational stability across diverse applications, from industrial process water to municipal wastewater treatment.

By tackling these fundamental challenges, the technology transforms the economics of water reuse. The reduced maintenance requirements, lower energy consumption, and improved treatment consistency make water recycling more financially viable across a broader range of applications.

Applications and Success Stories

The real-world impact of Swirltex’s innovative membrane technology spans multiple industries, with each implementation showcasing unique solutions to complex wastewater challenges. In the oil and gas sector, a major producer faced persistent membrane fouling issues while treating produced water. After implementing Swirltex’s bubbly flow system, membrane cleaning frequency dropped by 70%, while treatment capacity increased by 40%.

A municipal wastewater treatment plant struggling with seasonal algae blooms found similar success. The facility had previously needed to shut down operations during peak bloom periods, creating significant service disruptions. Swirltex’s technology enabled continuous operation throughout algae events while maintaining consistent effluent quality and reducing chemical usage by 35%.

Perhaps the most striking example comes from the food and beverage industry, where a dairy processor was dealing with high-strength wastewater containing fats, oils, and proteins. Traditional membrane systems failed repeatedly due to severe fouling. The Swirltex installation not only handled the challenging waste stream but also achieved 98% water recovery – a 15% improvement over previous systems. The recovered water quality met standards for process reuse, creating a closed-loop system that saved the facility over 100 million liters of fresh water annually.

Mining operations have also benefited from this technology’s unique approach to difficult-to-treat waters. A copper mine implemented Swirltex units to handle tailings water with high suspended solids content. The system’s ability to maintain stable operation despite variable influent quality resulted in a 50% reduction in operational downtime and significant savings in replacement membrane costs.

What makes these success stories particularly noteworthy is how they demonstrate the technology’s versatility across different scales and applications. From small industrial facilities processing 50 cubic meters per day to large municipal plants handling thousands of cubic meters, the core benefits of reduced fouling, lower energy consumption, and improved recovery rates remain consistent. These implementations showcase how innovative membrane technology can effectively clear remote places’ problems while solving environmental issues.

Economic Value Proposition

The implementation of Swirltex technology delivers compelling financial returns through multiple interconnected pathways. At the core of the value proposition lies a dramatic reduction in operational expenses, primarily driven by the system’s unique bubble-enhanced separation process that significantly reduces energy consumption compared to conventional membrane systems.

By leveraging buoyancy to enhance separation, the technology requires up to 50% less energy to achieve the same treatment objectives. This translates directly to lower electricity costs – a major expense item for treatment facilities. The reduced operating pressure also means less wear and tear on equipment, extending membrane life by 2-3 times the industry standard.

Perhaps most significantly, the technology’s enhanced fouling resistance allows facilities to treat challenging wastewater streams that would typically require extensive pre-treatment or frequent cleaning cycles. By maintaining stable operation even with high-solids or oil-laden waters, facilities can minimize chemical cleaning requirements and avoid costly production interruptions.

This operational stability unlocks new opportunities for water reuse and resource recovery. Facilities can now economically treat and recycle wastewater streams that were previously too difficult or expensive to handle. The technology’s ability to handle variable feed quality also reduces the need for buffer tanks and other capital-intensive infrastructure.

Beyond direct cost savings, the technology enables facilities to increase their treatment capacity without major infrastructure investments. The higher flux rates and reduced downtime mean existing membrane systems can process more volume, deferring or eliminating the need for facility expansions. For new installations, the smaller footprint and simplified design reduce upfront capital costs.

When evaluated holistically, facilities implementing Swirltex typically see payback periods of 12-24 months through combined savings in energy, chemicals, maintenance, and avoided capital expenditures. The technology’s reliability and performance consistency also provide intangible benefits through reduced operational complexity and improved compliance certainty.

Regulatory Compliance and Environmental Impact

As environmental regulations grow increasingly stringent worldwide, wastewater treatment facilities face mounting pressure to improve their treatment processes while reducing their ecological footprint. The innovative Swirltex membrane technology addresses both challenges through its unique bubble-enhanced separation approach.

The technology’s enhanced solids removal capabilities consistently achieve effluent quality that meets or exceeds regulatory requirements across multiple jurisdictions. By effectively removing suspended solids, oils, and other contaminants in a single pass, facilities can maintain reliable compliance with discharge permits while reducing the risk of violations and associated penalties.

From an environmental perspective, the system’s lower energy consumption directly translates to reduced greenhouse gas emissions. The bubble-assisted filtration process requires significantly less pressure to operate compared to conventional membrane systems, resulting in up to 50% lower energy usage. For a typical municipal treatment plant, this can mean hundreds of tons of avoided CO2 emissions annually.

The technology also minimizes chemical usage through improved mechanical separation. As highlighted in how to treat wastewater in a net grid positive way while mimicking your body, reduced chemical dependency not only cuts operating costs but also decreases the environmental impact of treatment processes. The system’s ability to handle varying influent qualities without chemical adjustments further supports facilities’ sustainability goals.

Water reuse applications particularly benefit from the technology’s reliable performance. The high-quality effluent produced enables facilities to confidently implement water recycling programs, reducing their freshwater withdrawal needs and supporting circular economy initiatives. This becomes increasingly critical as regions face growing water scarcity challenges and tightening restrictions on water consumption.

The compact footprint of Swirltex installations also minimizes land use requirements compared to conventional treatment systems. This spatial efficiency not only reduces construction impacts but also preserves valuable land that might otherwise be needed for treatment infrastructure expansion. The modular nature of the technology further allows for capacity increases without significant additional land requirements.

Future Applications and Development

As Swirltex’s membrane technology continues to evolve, researchers are exploring groundbreaking applications across diverse industries. The technology’s unique bubble-enhanced separation capabilities open new possibilities for treating complex wastewater streams that traditional membranes struggle to handle.

One promising direction is the adaptation of the technology for the food and beverage sector. The ability to efficiently separate oils, fats, and suspended solids makes it particularly valuable for dairy processing, breweries, and meat processing facilities. Engineers are fine-tuning the bubble injection parameters to optimize separation of specific contaminants common in these industries.

In the mining sector, ongoing trials demonstrate the technology’s potential for treating acid mine drainage and recovering valuable minerals from waste streams. The enhanced separation efficiency could make previously uneconomical recovery processes viable while reducing environmental impact. Research teams are investigating modified membrane materials specifically designed for selective metal ion removal.

Perhaps most intriguingly, development is underway to scale down the technology for decentralized applications. Compact, modular units could serve remote communities or industrial facilities where traditional infrastructure is impractical. This aligns with the growing trend toward distributed water treatment systems, as discussed in the shift toward onsite water reuse.

The next phase of R&D focuses on intelligent process control systems that automatically adjust operating parameters based on influent characteristics. Machine learning algorithms are being developed to optimize bubble size, frequency, and membrane cleaning cycles in real-time. This could dramatically reduce operator oversight requirements while improving treatment consistency.

Researchers are also exploring novel membrane materials and surface modifications to enhance fouling resistance and separation selectivity. Early results suggest potential breakthroughs in treating emerging contaminants like microplastics and pharmaceutical compounds. As regulatory standards tighten globally, these capabilities could prove invaluable across multiple sectors.

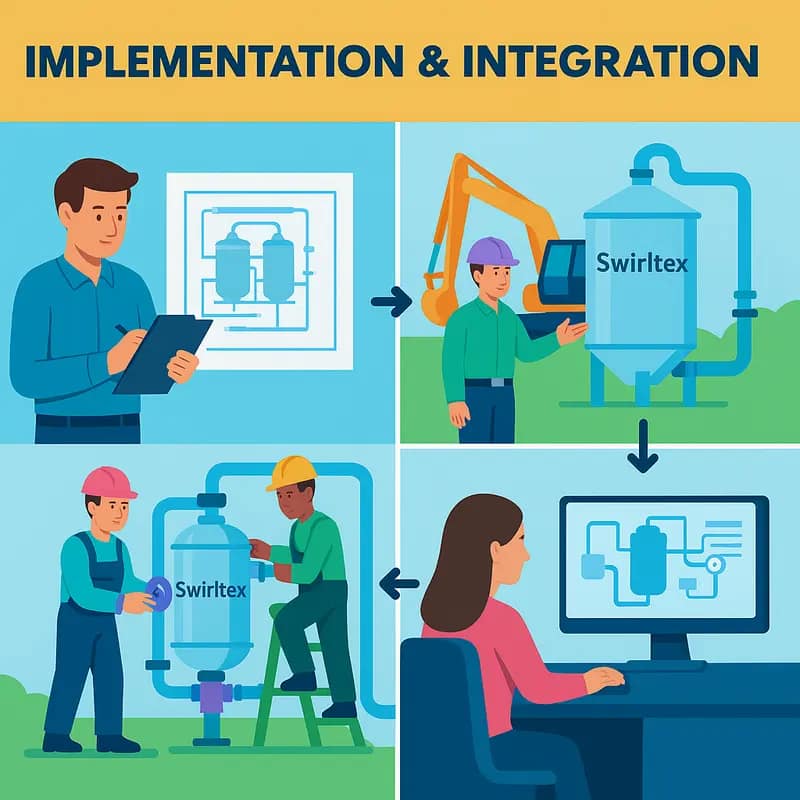

Implementation and Integration

The successful deployment of Swirltex technology requires careful planning and systematic integration with existing wastewater treatment infrastructure. Plant operators must first evaluate their current treatment train to identify optimal insertion points for the membrane system. Most facilities integrate Swirltex modules as a tertiary treatment step, though some applications may benefit from earlier implementation.

The physical installation involves minimal disruption to ongoing operations. The modular nature of the technology allows for phased implementation, starting with pilot units before scaling to full capacity. Essential infrastructure modifications typically include piping connections, power supply, and control system integration. The membrane units’ compact footprint means most facilities can accommodate them within existing space constraints.

Operational integration focuses on establishing optimal process parameters. This astonishing technology will turn the wastewater sector on its head through its unique bubble-enhanced separation process. Operators must carefully calibrate bubble injection rates, cross-flow velocities, and transmembrane pressures to achieve peak performance. Modern SCADA systems can automate much of this optimization, though initial manual adjustments help establish baseline parameters.

Staff training represents another crucial implementation component. While the technology’s operation is straightforward, maintenance personnel need instruction on membrane cleaning protocols, monitoring procedures, and troubleshooting techniques. Most facilities can complete basic training within a few days, with advanced operational expertise developing over several months of hands-on experience.

Ongoing optimization involves regular performance monitoring and periodic process adjustments. Key metrics include permeate quality, energy consumption, and membrane longevity. The technology’s inherent flexibility allows operators to fine-tune parameters in response to varying influent characteristics or treatment objectives. This adaptability ensures sustained performance even as operational conditions evolve over time.

Investment and Growth Potential

The wastewater treatment market presents a compelling investment opportunity for Swirltex’s innovative membrane technology. With global water reuse expected to grow at 14% annually through 2028, the addressable market for advanced treatment solutions exceeds $50 billion. Swirltex’s unique approach to membrane filtration positions it to capture significant market share in both industrial and municipal applications.

The technology’s competitive advantages stem from its revolutionary bubbly membrane design. By reducing energy consumption by up to 40% compared to conventional systems while improving separation efficiency, Swirltex delivers measurable cost savings that drive rapid customer adoption. The system’s ability to handle high-solids waste streams opens additional revenue streams in challenging industrial sectors like oil & gas, food processing, and mining.

From an investment perspective, Swirltex demonstrates strong unit economics and scalability. The technology’s modular design enables quick deployment and easy capacity expansion, while recurring revenue from membrane replacement and maintenance services provides stable cash flows. Early customer implementations have validated 12-18 month payback periods, making the value proposition highly attractive to potential clients.

Market validation has come through strategic partnerships with major industrial players and successful pilot projects across multiple sectors. The company’s intellectual property portfolio, including patents on its core bubble-enhanced separation process, creates barriers to entry and preserves long-term competitive advantages.

Key growth vectors include geographic expansion into water-stressed regions, particularly in the Middle East and Asia Pacific, where water reuse adoption is accelerating. The technology’s ability to treat complex waste streams positions it well for emerging applications in pharmaceutical manufacturing, electronics production, and other advanced industrial processes.

While challenges exist around scaling manufacturing capacity and building out a global service infrastructure, Swirltex’s capital-efficient business model and strong margins support reinvestment in growth. As regulations around water reuse tighten globally, demand for more efficient treatment solutions will continue rising, creating tailwinds for adoption.

The Bubble That Started It All

Sometimes the most revolutionary innovations emerge from life’s simplest observations. For Peter Christou, that moment came while watching soap bubbles float through the air, carrying tiny particles in their wake. This casual observation would eventually lead to a breakthrough in membrane technology that’s transforming wastewater treatment.

Christou noticed how bubbles naturally trapped and transported particles through fluid, much more efficiently than traditional filtration methods. This sparked an idea: what if this natural phenomenon could be harnessed to enhance membrane filtration? The concept seemed promising, but translating it into a practical solution would prove challenging.

After years of research and development, Christou and his team discovered that by introducing microbubbles into wastewater streams in a controlled spiral pattern, they could dramatically improve membrane performance. The bubbles created a natural lifting effect, preventing particles from settling and clogging the membrane surface – a persistent problem that had plagued the industry for decades.

The technology works by generating a unique flow pattern that combines centrifugal forces with buoyancy effects. As wastewater spirals through the system, suspended solids are pushed away from membrane surfaces, allowing clean water to pass through more efficiently. This seemingly simple principle has profound implications for treatment economics.

What makes this innovation particularly remarkable is its elegant simplicity. Like nature’s most effective solutions, it harnesses fundamental physical principles rather than relying on complex chemical processes or energy-intensive mechanisms. The result is a more robust and energy-efficient treatment process that can handle challenging waste streams that traditional membranes struggle with.

The journey from soap bubble observation to commercial technology wasn’t straightforward. It required countless iterations, failed experiments, and persistent refinement. But Christou’s unwavering focus on the core principle – letting bubbles do the heavy lifting – ultimately led to a solution that’s elegantly effective in its simplicity.

Breaking Down the Science

At the core of this innovative membrane technology lies a deceptively simple but powerful principle: the strategic use of microbubbles in a controlled spiral flow pattern. When wastewater enters the system, microbubbles are introduced in precise quantities and sizes, typically ranging from 20-100 microns in diameter. These bubbles attach themselves to suspended solids and contaminants through a process known as bubble flotation.

What sets this approach apart is the engineered spiral flow pattern. As the water-bubble mixture moves through specially designed membrane tubes, centrifugal forces create a unique fluid dynamics phenomenon. The lighter bubble-solid combinations naturally migrate toward the center of the spiral, while cleaner water moves to the outer edges. This natural separation significantly reduces membrane fouling – a persistent challenge in conventional filtration systems that typically forces frequent cleaning cycles and increases operational costs.

The physics behind this process leverages both buoyancy and centrifugal forces. When microbubbles attach to particles, they create bubble-particle agglomerates with densities significantly lower than water. The spiral flow pattern then amplifies this density difference, creating a clean separation zone near the membrane surface. This protective boundary layer prevents larger particles from reaching and clogging the membrane pores.

The membrane itself features optimized pore sizes and surface chemistry that complement the bubble-enhanced separation. This synergy allows for higher flux rates – the volume of water that can pass through a given membrane area – while maintaining excellent filtration quality. The system can handle varying contaminant loads without compromising performance, as the bubble generation and spiral flow automatically adjust to changing conditions.

Perhaps most remarkably, this approach requires significantly less energy than conventional membrane systems. The microbubbles, once generated, help maintain the spiral flow pattern with minimal additional energy input. This self-sustaining characteristic, combined with reduced cleaning requirements, translates to lower operational costs and improved sustainability.

Real-World Applications and Success Stories

The transformative impact of Swirltex’s membrane technology becomes evident through several compelling industrial applications. At a major food processing facility in Alberta, the implementation of Swirltex’s system achieved a remarkable 85% reduction in suspended solids while cutting energy consumption by 40% compared to conventional membrane systems. The facility now reuses 75% of its process water, saving over 500,000 gallons annually.

In the oil and gas sector, a prominent operator faced challenges with produced water treatment. After installing Swirltex’s technology, they achieved consistent compliance with discharge requirements while handling variable influent quality. The microbubble-enhanced system maintained stable operation even when total dissolved solids fluctuated between 5,000 and 40,000 mg/L, a feat previously unattainable with standard membranes.

Perhaps most impressive is the technology’s application in municipal wastewater treatment. A mid-sized facility serving 50,000 residents implemented Swirltex as part of their tertiary treatment upgrade. The system’s unique spiral flow pattern prevented membrane fouling so effectively that cleaning frequency decreased by 60%, while permeate quality improved to consistently meet stringent reuse standards.

In the brewing industry, where water quality directly impacts product taste, a craft brewery installed a Swirltex unit to treat process wastewater. The system achieved 99.9% removal of suspended solids and reduced chemical oxygen demand by 95%, enabling direct reuse in non-product applications. This success has sparked interest across the beverage sector, where water conservation increasingly affects the bottom line.

These results demonstrate how Swirltex’s innovative approach to membrane filtration delivers tangible benefits across diverse applications. The technology’s ability to handle challenging waste streams while reducing operational costs has proven particularly valuable in industries where conventional membrane systems struggle.

Economic Advantages and ROI Analysis

The implementation of Swirltex membrane technology presents compelling economic benefits that fundamentally reshape the cost structure of wastewater treatment operations. Analysis of operational data reveals a 30-40% reduction in energy consumption compared to conventional membrane systems, primarily due to its innovative bubble-assisted filtration mechanism that significantly reduces pumping requirements.

Capital expenditure benefits emerge from the technology’s ability to handle higher solid loads without requiring extensive pre-treatment infrastructure. Facilities can achieve the same treatment capacity with approximately 25% less membrane surface area, translating to reduced initial investment costs. The system’s compact footprint further minimizes civil engineering expenses and real estate requirements.

Operational cost advantages stem from multiple sources. The unique swirling pattern created by the technology prevents membrane fouling, extending cleaning intervals by up to 300% and reducing chemical consumption by 40-50%. Labor costs decrease due to less frequent maintenance requirements and simplified operational procedures.

A typical ROI analysis for a municipal wastewater treatment plant demonstrates payback periods of 2-3 years, considering both direct and indirect savings. Direct savings include reduced energy bills, chemical costs, and maintenance expenses. Indirect benefits encompass increased operational uptime, reduced waste handling costs, and improved treated water quality that opens opportunities for water reuse revenue streams.

Long-term financial projections show that facilities implementing Swirltex technology can expect a 15-20% reduction in total lifecycle costs over a 20-year period. This calculation factors in initial capital investment, operational expenses, maintenance requirements, and the extended lifespan of membrane components due to reduced fouling stress.

Particularly noteworthy is the technology’s scalability advantage. Unlike traditional systems that often face diminishing returns at larger scales, Swirltex maintains its economic benefits across varying facility sizes, making it equally attractive for both small decentralized operations and large municipal plants.

Read more about maximizing ROI in water treatment projects

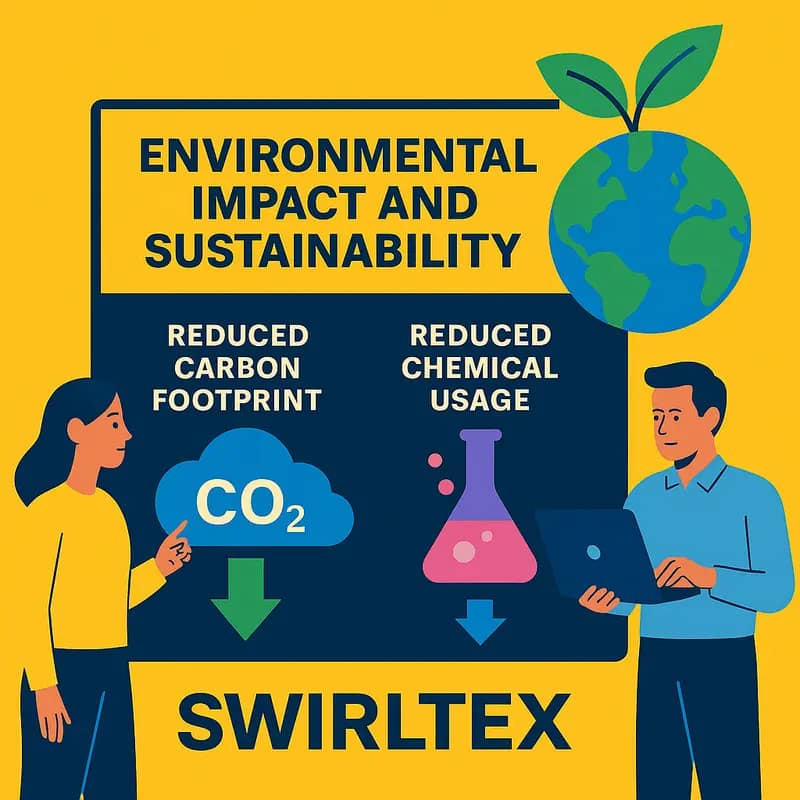

Environmental Impact and Sustainability

The environmental benefits of Swirltex’s innovative membrane technology extend far beyond conventional wastewater treatment approaches. At its core, the system’s unique bubbly design significantly reduces the need for chemical cleaning agents – a major environmental concern in traditional membrane operations. By leveraging fluid dynamics to prevent fouling, facilities can cut chemical usage by up to 70%, keeping harmful cleaning compounds out of waterways.

Perhaps even more impactful is the technology’s dramatic reduction in energy consumption. The membrane system operates at lower pressures than conventional technologies, translating to 30-50% less electricity usage. For a typical municipal treatment plant processing 10 million gallons per day, this could mean reducing carbon emissions by over 500 metric tons annually – equivalent to taking over 100 cars off the road.

This improved energy efficiency ties directly to enhanced water sustainability. The lower operating pressures enable facilities to treat challenging wastewater streams that would otherwise be too costly or energy-intensive to process. More water can be cleaned and safely reused rather than discharged, helping preserve freshwater resources and reduce strain on aquatic ecosystems.

The technology’s modular design also minimizes environmental disruption during implementation. Rather than requiring extensive new infrastructure, Swirltex units can integrate into existing treatment trains with minimal site preparation or construction impacts. The small physical footprint preserves land use while the plug-and-play nature reduces waste from installation.

As outlined in articles like ‘how to cut wastewaters energy-related carbon emissions in two at no cost’, these efficiency gains compound over time to deliver lasting environmental benefits. The reduced chemical and energy requirements create a positive feedback loop – less resource consumption means lower environmental impact, which in turn reduces the treatment burden on natural systems. This represents a crucial step toward more sustainable water management practices that work in harmony with, rather than against, natural processes.

Future Applications and Market Potential

The innovative membrane technology behind Swirltex stands poised to transform numerous industries beyond traditional wastewater treatment. The oil and gas sector presents a particularly promising opportunity, where the technology’s ability to handle high concentrations of suspended solids and oil content could revolutionize produced water treatment. Early pilot projects have demonstrated up to 40% cost reductions compared to conventional separation methods.

Food and beverage manufacturing represents another key growth market. The technology’s gentle separation approach preserves valuable product components while removing contaminants, making it ideal for applications like dairy processing and beverage clarification. Several major food processors are already exploring implementations that could reduce water consumption by up to 30%.

Geographically, water-stressed regions across Asia and the Middle East show strong potential for adoption. The technology’s lower energy requirements and chemical-free operation align with sustainability goals while delivering compelling operational savings. Municipal utilities in these regions could benefit from retrofitting existing plants to handle higher loads without major infrastructure investments.

Emergent applications in mining and mineral processing highlight the versatility of the technology. The ability to efficiently separate fine particles while maintaining consistent flow rates addresses long-standing challenges in tailings management and process water recovery. This could unlock significant value in an industry facing mounting environmental pressures.

As water reuse becomes increasingly critical for industrial sustainability, the market for advanced separation technologies is projected to exceed $15 billion by 2025. Swirltex’s innovation is well-positioned to capture a meaningful share through its demonstrated advantages in operational efficiency, maintenance requirements, and environmental impact.

The technology’s scalability from small decentralized systems to large industrial installations provides flexibility to address diverse market needs. This adaptability, combined with growing regulatory pressure for water conservation and reuse, creates favorable conditions for accelerated commercial adoption across multiple sectors.

Final words

As the water industry continues to evolve, Swirltex stands at the forefront of membrane technology innovation. Their bubble-enhanced approach not only solves critical operational challenges but also opens new possibilities for water reuse and treatment efficiency. The technology’s proven success across various applications, combined with its compelling economic benefits, positions Swirltex as a valuable solution for water treatment facilities worldwide. For investors, operators, and industry leaders, Swirltex represents more than just a technological advancement – it’s a pathway to more sustainable and efficient water treatment operations. The company’s continued innovation and expansion into new markets suggest a bright future in addressing global water challenges. As water scarcity and treatment demands increase, technologies like Swirltex will play a crucial role in shaping the future of water treatment and reuse.

Get the Water Sector’s Pulse weekly for free: subscribe to my Newsletter ➡️

About us

I offer (hopefully!) unique and insightful coverage of the water industry by combining my hard-earned technical expertise with engaging storytelling. If you haven’t yet, it might be time for you to subscribe to the podcast, the youtube channel and/or the newsletter!

(I’d do it if I were you, but I’m slightly biased 😉)