In an era where water quality concerns dominate headlines, FREDsense Technologies emerges as a beacon of innovation in the water monitoring landscape. This Canadian biotechnology company has developed a groundbreaking approach to water quality testing that combines the precision of biological sensors with the convenience of automated systems. By harnessing the power of genetically modified bacteria as microscopic detection agents, FREDsense offers water professionals an unprecedented ability to monitor contaminants in real-time, potentially saving millions in operational costs while ensuring water safety at a molecular level.

with 🎙️ Emily Hicks, COO & Co-Founder at FREDsense

Take-home message (in 2 long sentences 😅):

FREDsense delivers rapid, field-deployable PFAS testing that turns weeks of water analysis into just hours, using a proprietary bio-inspired polymer that binds to contaminants and gives immediate results. What makes them truly revolutionary in the water industry is their ability to detect total PFAS at parts-per-trillion levels with portable technology, empowering customers from airports to remediation sites with on-site data that previously required expensive lab analysis and month-long waits.

In this episode, you’ll learn:

🧪 How FREDsense revolutionized PFAS detection with their biosensor platform and what makes their technology unique among competitors

💵 Why rapid PFAS testing creates massive value for utilities, airports, and treatment technology providers compared to traditional lab methods

🔬 What the technical challenges are in detecting PFAS at parts-per-trillion levels and how their bio-inspired polymer system overcomes these limitations

⚙️ How the company pivoted from arsenic detection to COVID testing before finally finding strong product-market fit with their PFAS field kit solution

🌊 If current online PFAS sensor technology could transform treatment economics by allowing companies to optimize their destruction processes in real-time

Let’s get into it!

The Birth of Biological Innovation

In a laboratory at the University of Calgary, a group of forward-thinking students embarked on a journey that would transform water quality monitoring. The FREDsense story began as an ambitious research project, where founders David Lloyd and Robert Mayall sought to harness the natural sensing abilities of bacteria to detect water contaminants.

Their breakthrough came from a deceptively simple observation: certain bacteria naturally respond to specific chemicals in water. By genetically modifying these microorganisms and coupling them with sophisticated electronic sensors, the team created a revolutionary biosensor platform that could detect minute traces of contaminants in real-time.

The transition from academic project to commercial enterprise wasn’t straightforward. The team faced the challenge of convincing industry veterans that living organisms could reliably monitor water quality. They spent countless hours optimizing their bacterial sensors, ensuring they could withstand real-world conditions while maintaining accuracy.

What set FREDsense apart was their unique approach to environmental monitoring. Unlike traditional chemical testing methods that required complex laboratory analysis, their biosensors provided immediate results onsite. This innovation addressed a crucial gap in the water monitoring industry, where time-sensitive decisions often relied on delayed laboratory results.

By combining biotechnology expertise with environmental science principles, FREDsense developed a modular platform that could be adapted to detect various contaminants. This versatility proved crucial in attracting early adopters from both municipal water authorities and industrial clients.

The company’s evolution mirrors the broader transformation in environmental monitoring, where innovative biological approaches are increasingly replacing conventional chemical testing methods. Through persistent refinement and validation of their technology, FREDsense has established itself as a pioneer in biological sensor technology, demonstrating that nature’s own mechanisms can offer superior solutions to complex environmental challenges.

The Science Behind the Sensors

At the core of FREDsense’s revolutionary approach lies an elegant fusion of biology and electronics. The company’s biosensor technology harnesses genetically modified bacteria that act as living detection systems, fundamentally transforming how we monitor water quality.

These specialized bacterial sensors contain engineered genetic circuits that respond to specific contaminants in water. When target compounds are present, the bacteria produce a measurable electrical signal through a process called bioelectrical signal transduction. The bacterial cells essentially function as microscopic transducers, converting the presence of contaminants into quantifiable electrical outputs.

The genetic modification process involves inserting specific DNA sequences that code for proteins capable of recognizing target contaminants. When these proteins interact with the contaminants, they trigger a cascade of cellular reactions that ultimately generates an electrical current. This bioelectrical signal is then amplified and processed through sophisticated electronics integrated into the sensor platform.

What makes this approach particularly powerful is its specificity and sensitivity. Unlike traditional chemical sensors, these bacterial biosensors can be precisely engineered to detect exact compounds of interest while ignoring similar but irrelevant molecules. The technology can detect contaminants at extremely low concentrations – often in parts per billion – providing unprecedented accuracy in water quality monitoring.

The real-time data generated by these biosensors is processed through advanced algorithms that translate the electrical signals into actionable water quality metrics. This enables continuous monitoring without the need for complex sample preparation or laboratory analysis. The system’s ability to provide instant feedback represents a significant advance over conventional water testing methods that can take days or weeks to deliver results.

Perhaps most remarkably, the bacterial sensors are self-regenerating and can function continuously for extended periods, making them ideal for long-term deployment in water monitoring systems. This sustainable approach to water quality testing, discussed in detail in this analysis of biomimicry applications, demonstrates how biological systems can be harnessed to solve complex environmental challenges.

Real-World Applications and Impact

FREDsense’s biosensor technology has demonstrated remarkable success across multiple critical water monitoring applications. In a groundbreaking deployment at a major mining operation in Alberta, the company’s real-time detection system reduced traditional testing times from weeks to mere hours while maintaining accuracy above 95%. This implementation alone generated over $300,000 in annual cost savings through reduced lab testing and optimized treatment processes.

The technology’s impact extends beyond the mining sector. A municipal water treatment facility in Ontario leveraged FREDsense’s biosensors to monitor trace metal contamination continuously. The system detected a potentially hazardous spike in lead levels that traditional periodic testing would have missed, enabling immediate corrective action and protecting public health. This early warning capability has become a cornerstone of the facility’s water safety protocol.

Perhaps most notably, FREDsense partnered with an industrial wastewater treatment plant facing persistent compliance challenges. By deploying their biosensors at key monitoring points, the facility achieved real-time visibility into contaminant levels. This data-driven approach enabled proactive treatment adjustments, resulting in a 40% reduction in compliance violations and an estimated $500,000 in avoided regulatory penalties.

A particularly innovative application emerged through collaboration with environmental researchers studying groundwater contamination near abandoned industrial sites. The portability and rapid deployment capabilities of FREDsense’s technology enabled comprehensive site assessment in a fraction of the time and cost of conventional methods. This work, highlighted in recent environmental impact studies, demonstrates how biosensor innovation can accelerate environmental remediation efforts.

These implementations showcase how FREDsense’s technology transcends traditional monitoring limitations by providing continuous, accurate, and actionable data. The technology’s versatility across diverse applications, from industrial compliance to environmental protection, underscores its potential to revolutionize water quality management practices globally.

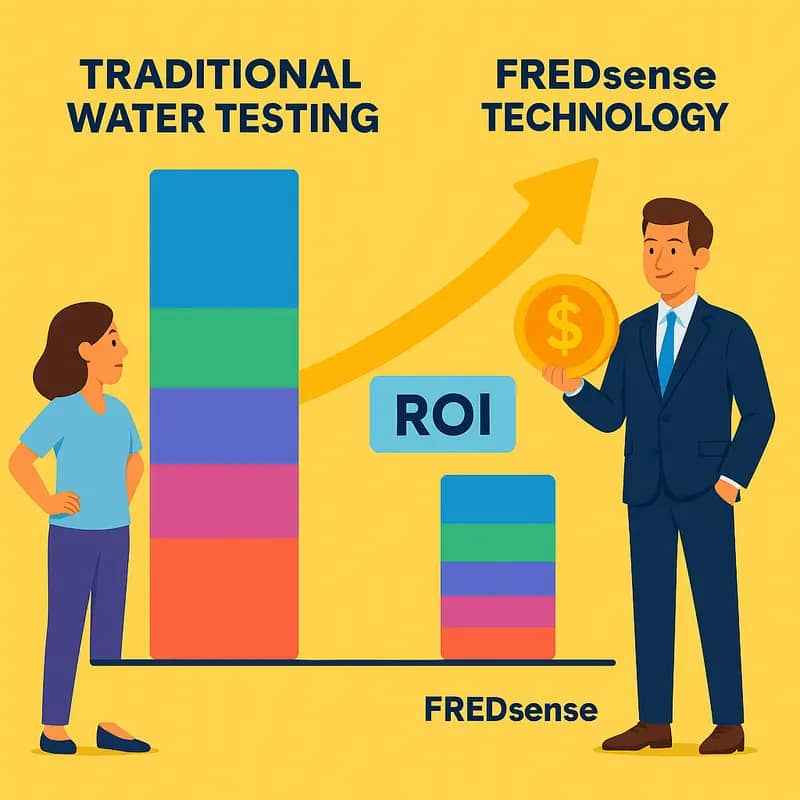

Market Disruption and Economic Benefits

FREDsense’s biological sensor technology is fundamentally reshaping the economics of water quality monitoring by addressing longstanding inefficiencies in traditional testing methods. The company’s innovative biosensor platform delivers real-time results at a fraction of the cost of conventional laboratory analysis, creating ripple effects across the water quality monitoring market.

The economic advantages manifest in multiple ways. Traditional water testing often requires sample collection, transportation to labs, and complex analytical procedures that can take days or weeks. FREDsense’s approach eliminates most of these steps, enabling on-site, continuous monitoring that drastically reduces labor costs and time investments. Early adopters report cost savings of up to 70% compared to traditional testing methods.

Beyond direct cost reductions, the technology’s real-time capabilities enable proactive maintenance and early problem detection. This preventive approach helps facilities avoid costly emergency responses and potential regulatory violations. Water treatment plants using the system report significant reductions in chemical usage and energy consumption through more precise dosing and process control.

The market impact extends to competitive dynamics within the water quality monitoring sector. Traditional testing laboratories face pressure to adapt their business models as FREDsense’s technology demonstrates superior price-performance metrics. The company’s success has sparked increased investment in biosensor development across the industry, accelerating innovation and further driving down costs.

Perhaps most significantly, FREDsense’s solution makes comprehensive water quality monitoring financially feasible for smaller municipalities and industrial facilities that previously found extensive testing prohibitively expensive. This democratization of access expands the total addressable market while improving environmental protection and public health outcomes across a broader spectrum of communities.

The economic disruption continues to accelerate as FREDsense scales its technology. Early success stories have caught the attention of major water utilities and industrial water users, creating a positive feedback loop of adoption, validation, and further market penetration. This momentum suggests the company’s impact on water quality monitoring economics will continue to grow in the coming years.

Regulatory Compliance and Validation

FREDsense’s biosensor technology demonstrates an unwavering commitment to regulatory compliance while setting new standards for water quality monitoring validation. Their biological sensing platform undergoes rigorous testing protocols that align with EPA, FDA, and international water quality standards, ensuring reliable performance across diverse testing environments.

The company’s validation process incorporates multi-layer verification systems that cross-reference results against established laboratory methods. This approach provides an additional layer of confidence in the accuracy of real-time measurements. The biological sensors undergo extensive calibration procedures using certified reference materials and demonstrate detection limits that meet or exceed regulatory requirements for various contaminants.

A distinctive aspect of FREDsense’s compliance strategy lies in their automated quality control systems. These systems continuously monitor sensor performance, automatically flagging any deviations from established parameters and initiating self-diagnostic routines. This proactive approach to quality assurance significantly reduces the risk of false readings and ensures data integrity.

The validation protocol includes comprehensive stability testing under various environmental conditions, ensuring consistent performance across temperature ranges, pH levels, and other potential interferents. Long-term reliability studies demonstrate sensor durability and measurement consistency over extended deployment periods, addressing a critical concern for water quality monitoring applications.

Particularly noteworthy is FREDsense’s approach to data validation. Their platform incorporates advanced statistical analysis tools that evaluate measurement uncertainty and provide confidence intervals for each reading. This statistical rigor adds another dimension to regulatory compliance by offering quantifiable reliability metrics that water quality managers can use to make informed decisions.

Collaboration with certified testing laboratories and regulatory bodies has been instrumental in validating the technology’s performance. These partnerships have resulted in peer-reviewed studies and independent verifications that document the platform’s capability to meet or exceed traditional testing methods’ accuracy while delivering results in a fraction of the time.

Future Developments and Research

FREDsense’s research pipeline signals an ambitious trajectory in biological sensor innovation, with several groundbreaking developments on the horizon. The company’s scientists are advancing a new generation of biosensors capable of detecting an expanded range of contaminants with unprecedented sensitivity and specificity.

A key focus area involves developing multi-parameter sensing capabilities that can simultaneously monitor multiple contaminants in a single measurement. This advancement would dramatically improve efficiency while reducing operational costs for water quality monitoring. The research team is also exploring novel biological recognition elements that could extend detection capabilities to emerging contaminants of concern, including pharmaceuticals and personal care products.

Significant system improvements are underway to enhance the platform’s robustness and reliability. Engineers are implementing advanced machine learning algorithms to optimize signal processing and reduce false positives, while also developing more sophisticated self-diagnostic capabilities to ensure continuous accurate performance. These improvements align with the growing need for autonomous monitoring systems that require minimal human intervention.

Particularly promising is the development of miniaturized sensor arrays that could enable distributed monitoring networks across water infrastructure systems. This innovation could revolutionize how utilities approach water quality management by providing real-time data from multiple points throughout their networks. The research team is also investigating ways to extend sensor lifespans and reduce maintenance requirements through improved biological stability and preservation techniques.

In collaboration with environmental scientists, FREDsense is exploring applications beyond traditional water quality monitoring. The company’s biosensor technology shows potential for monitoring industrial processes, agricultural runoff, and even space-based water recycling systems. This expansion into new applications demonstrates the versatility and adaptability of their core technology.

Critically, these developments are being pursued with a focus on practical implementation and scalability. The research team maintains close collaboration with industry partners to ensure that innovations address real-world challenges while meeting regulatory requirements and operational constraints.

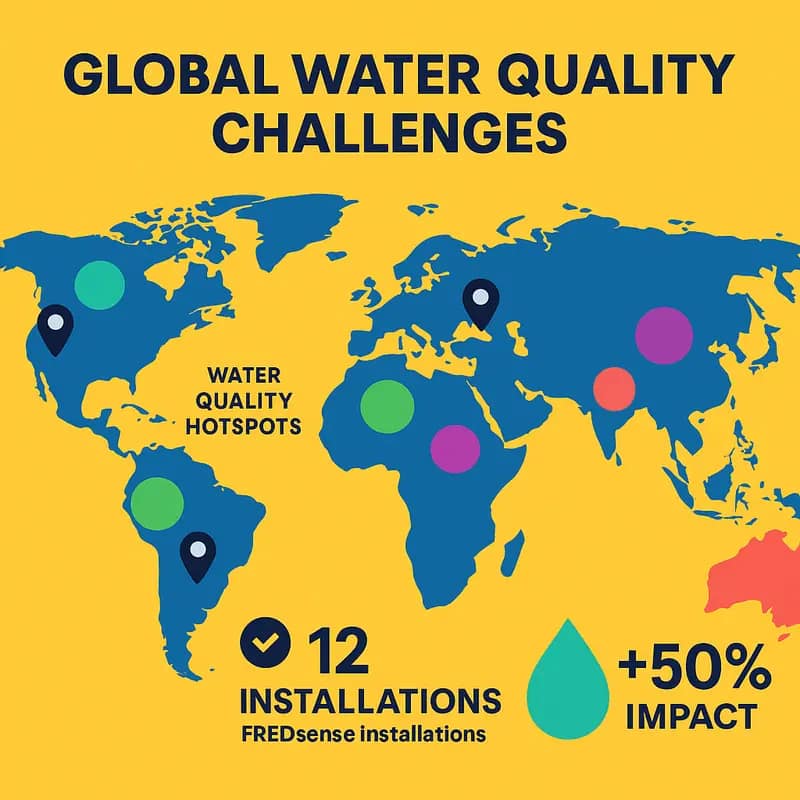

Global Water Quality Challenges

The global water crisis presents an unprecedented challenge in monitoring and ensuring water quality across diverse environments. Traditional water testing methods often require extensive lab infrastructure, skilled personnel, and lengthy processing times – creating critical gaps in water quality data that impact billions of lives. FREDsense’s biosensor technology directly addresses these fundamental monitoring challenges through a revolutionary approach to real-time detection.

By leveraging engineered biological sensors, FREDsense enables rapid, on-site detection of harmful contaminants without requiring complex sample preparation or laboratory analysis. This capability transforms water quality monitoring from an intermittent sampling activity into continuous surveillance, allowing water operators to identify and respond to contamination events as they occur. The technology’s ability to detect trace amounts of metals, nutrients, and industrial chemicals provides an unprecedented window into water quality dynamics.

The implications for global water security are profound. In regions lacking robust testing infrastructure, FREDsense’s portable biosensor units can provide immediate insights into water safety. The technology’s versatility makes it equally valuable across municipal water systems, industrial operations, and environmental monitoring applications. This adaptability is crucial as communities worldwide face mounting pressure from emerging contaminants, aging infrastructure, and climate change impacts on water resources.

Perhaps most significantly, FREDsense’s approach democratizes sophisticated water quality analysis. By simplifying the testing process and delivering clear, actionable data, the technology empowers a broader range of stakeholders to actively participate in water quality management. This shift from centralized testing to distributed monitoring networks creates a more resilient and responsive water security framework.

As highlighted in how water technologies matter in lithium mining and why you should buy now, innovations in water quality monitoring are becoming increasingly critical across industries. FREDsense’s biosensor platform represents a paradigm shift in how we detect, track, and respond to water quality challenges – marking a crucial step forward in addressing global water security concerns.

Investment and Growth Opportunities

FREDsense’s innovative biosensor technology positions the company for significant growth in the expanding water quality monitoring market. Market analysts project the global water quality monitoring systems market to reach $5.38 billion by 2025, with a compound annual growth rate of 7.3%. FREDsense is strategically positioned to capture a meaningful share of this growing market.

The company’s expansion strategy focuses on three key pillars: geographic expansion, product development, and strategic partnerships. Currently concentrated in North America, FREDsense plans to extend its reach into European and Asian markets where water quality concerns are driving demand for advanced monitoring solutions. Product development initiatives aim to broaden the range of contaminants their biosensors can detect while reducing per-unit costs through economies of scale.

For investors, FREDsense presents compelling opportunities across multiple dimensions. The company’s intellectual property portfolio, including several patents for its biosensor technology, provides strong barriers to entry and competitive advantages. Revenue streams combine hardware sales with recurring monitoring service fees, creating predictable cash flows and high customer retention rates.

Stakeholder opportunities extend beyond direct financial returns. Municipal utilities implementing FREDsense systems can achieve significant cost savings through early contamination detection and preventive maintenance. Industrial customers benefit from real-time monitoring that ensures regulatory compliance and optimizes treatment processes. Environmental organizations gain access to more comprehensive water quality data to support conservation efforts.

Looking ahead, the water technology investment landscape shows promising returns. FREDsense’s focus on developing scalable, cost-effective solutions addresses a critical market need while contributing to global water security goals. The company’s strong research and development pipeline, combined with growing market demand for innovative water quality monitoring solutions, suggests sustained growth potential for years to come.

The Biology-Technology Convergence

At the intersection of synthetic biology and sensor technology lies FREDsense’s groundbreaking approach to water quality monitoring. The company’s innovation stems from harnessing engineered bacteria that act as highly specific biological sensors, capable of detecting minute concentrations of contaminants in water samples.

The core technology relies on bacteria that have been genetically modified to respond to specific chemical compounds. When these bacteria encounter their target contaminant, they generate an electrical signal that can be precisely measured. This bio-electrochemical reaction creates a direct correlation between contaminant concentration and electrical output, enabling accurate quantification.

Unlike traditional water testing methods that often require complex sample preparation and expensive laboratory equipment, this biosensor technology offers several distinct advantages. The engineered bacteria provide exceptional specificity, eliminating false positives that plague many conventional testing approaches. The biological component also allows for continuous monitoring, as the bacteria remain active and responsive over extended periods.

The electronic interface transforms these biological responses into digital data in real-time. Advanced algorithms process the signals to deliver accurate concentration measurements within minutes, compared to the days or weeks required for traditional laboratory analysis. This rapid detection capability enables swift responses to water quality issues, potentially preventing widespread contamination events.

Perhaps most remarkably, the integration of biology with electronics creates a self-contained system that can operate autonomously. The bacteria essentially function as living sensors, eliminating the need for expensive reagents or complex sample preparation steps. This dramatically reduces both the cost and complexity of water quality monitoring while maintaining professional-grade accuracy.

The implications of this biology-technology convergence extend beyond just efficient testing. Much like how nature has evolved precise mechanisms to detect environmental changes, these engineered biosensors represent a new paradigm in environmental monitoring that combines the specificity of biological systems with the reliability of modern electronics.

This innovative approach, which fundamentally reimagines how we detect water contaminants, connects to broader discussions about biomimicry’s role in environmental solutions. The technology demonstrates how biological principles can be adapted and enhanced through engineering to create more effective solutions to environmental challenges.

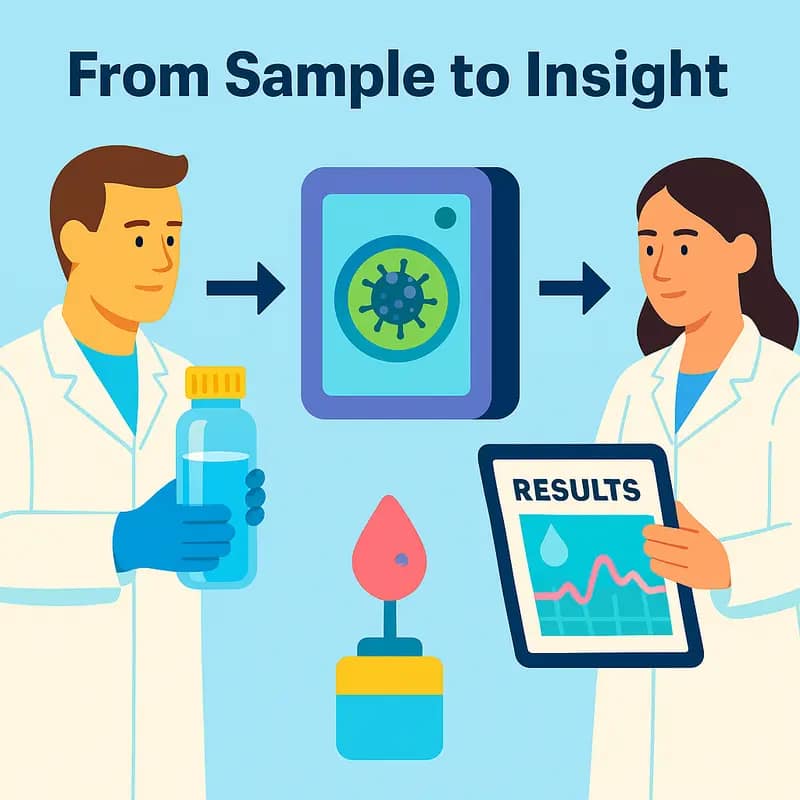

From Sample to Insight

At the heart of FREDsense’s revolutionary approach lies a streamlined process that transforms water sampling from a complex laboratory procedure into an automated, field-ready analysis. The system initiates with a straightforward sample collection, where operators need only collect water in designated containers – no specialized training required.

Once collected, the sample flows through an innovative biosensor cartridge containing the engineered bacterial sensors. These microscopic detectives immediately begin responding to target compounds in the water, generating measurable electrical signals within minutes. The proprietary electronic interface captures these bioelectrical responses in real-time, while sophisticated algorithms translate the raw data into actionable water quality metrics.

What truly sets this process apart is its remarkable automation. Unlike traditional methods requiring multiple manual steps and specialized expertise, the platform handles the entire workflow independently. The engineered bacteria, pre-loaded in sealed cartridges, remain stable and ready to deploy at a moment’s notice. When activated, internal quality controls ensure measurement accuracy while eliminating the need for complex calibration procedures.

The user interface presents results through an intuitive dashboard, making complex water chemistry accessible to operators of all skill levels. Rather than wrestling with spreadsheets or waiting days for lab reports, stakeholders can instantly view contaminant levels, track trends over time, and receive automated alerts if measurements exceed defined thresholds.

This seamless integration of biological sensing and digital automation delivers results in under an hour – a dramatic improvement over conventional testing methods that often require days or weeks. The technology behind this plug-and-play approach represents a significant leap forward, fundamentally changing how we monitor and respond to water quality challenges in real-world applications. The system’s ability to provide rapid, reliable results without specialized training makes advanced water quality monitoring accessible to utilities and industries of all sizes.

Market Impact and Applications

FREDsense’s biosensor technology is transforming water quality monitoring across multiple sectors, delivering unprecedented value through real-time detection capabilities. In municipal water treatment, the technology enables operators to continuously monitor contaminant levels and quickly respond to quality issues before they impact public health. This proactive approach has helped utilities reduce testing costs while improving regulatory compliance and public safety.

The mining and resource extraction industries have embraced this innovation to monitor process water and manage environmental impacts. By providing instant feedback on metal concentrations and other contaminants, operators can optimize their water treatment processes and minimize environmental risks. The technology’s ability to detect trace metals with high precision has proven particularly valuable for operations near sensitive ecosystems.

In the food and beverage sector, manufacturers rely on these biosensors to ensure product quality and safety. The system’s automated sampling and analysis capabilities allow for continuous monitoring of incoming water supplies and process streams, helping maintain consistent product quality while reducing manual testing requirements.

Perhaps most notably, the technology has found critical applications in environmental monitoring and remediation projects. Government agencies and environmental consultants use the platform to track contamination levels in groundwater, assess the effectiveness of cleanup efforts, and monitor long-term site conditions. The real-time data enables faster decision-making and more efficient resource allocation in remediation projects.

The petrochemical industry has also adopted this solution to monitor wastewater treatment systems and ensure regulatory compliance. The technology’s ability to detect specific compounds of concern while withstanding harsh industrial environments has made it particularly valuable in this sector. As regulations become increasingly stringent, many facilities are turning to these biosensors to maintain consistent compliance while reducing monitoring costs.

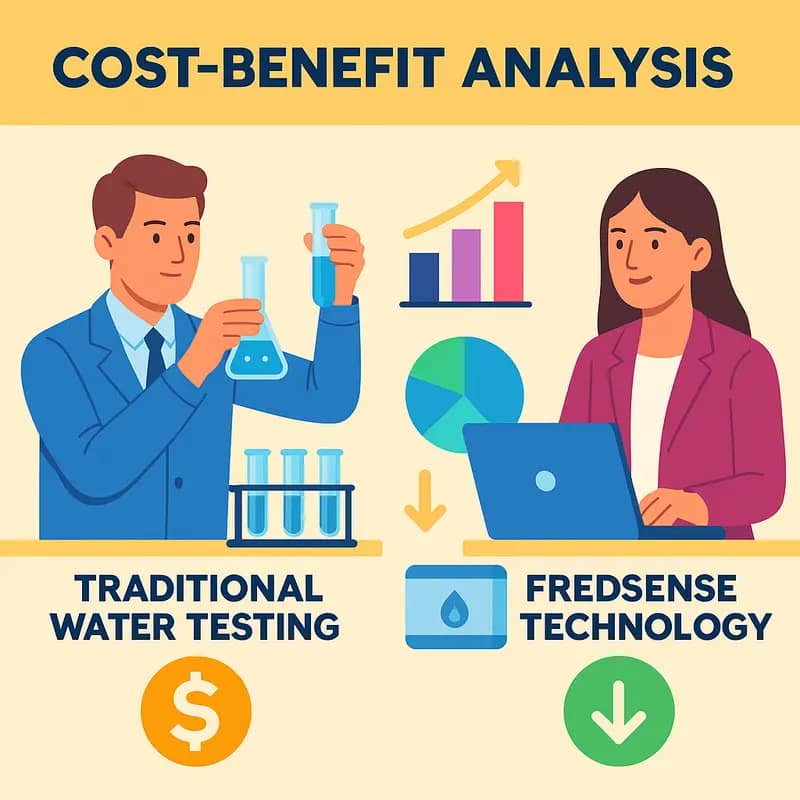

Cost-Benefit Analysis

The economic advantages of implementing biosensor-based water quality monitoring extend far beyond simple operational efficiencies. A detailed analysis reveals substantial cost savings across multiple dimensions when compared to traditional testing methods.

Laboratory analysis traditionally requires collecting samples, transporting them to testing facilities, and waiting days or weeks for results. This process incurs significant labor costs, transportation expenses, and analytical fees – often reaching hundreds of dollars per sample. In contrast, biosensor technology enables real-time, on-site monitoring that eliminates these recurring costs while providing continuous data streams.

Timely detection of water quality issues through continuous monitoring helps prevent costly system failures and contamination events. The economic incentives driving this shift mirror broader industry trends toward preventive approaches that maximize return on investment. Early detection can save facilities millions in potential damages, regulatory fines, and reputation costs.

Labor efficiency gains prove particularly compelling. While conventional testing methods require dedicated sampling teams and lab technicians, biosensor systems automate the monitoring process. This automation reduces staffing requirements by up to 70% for routine water quality assessment tasks. The freed personnel capacity can be redirected to higher-value activities like system optimization and preventive maintenance.

Accuracy improvements deliver additional economic benefits through reduced false positives and negatives. Traditional testing methods face inherent limitations in sample degradation during transport and processing delays. Real-time biosensor data eliminates these variables, providing more reliable results that enable confident operational decisions. This enhanced accuracy typically reduces unnecessary treatment interventions by 15-25%, generating substantial chemical and energy cost savings.

When factoring in all direct and indirect costs, the total economic advantage of biosensor implementation generally yields positive returns within 12-18 months. Ongoing savings then compound as operational efficiencies increase and maintenance costs decrease. This compelling economic case, combined with superior performance, positions biosensor technology as the clear path forward for water quality monitoring.

Regulatory Compliance and Validation

FREDsense’s innovative biosensor technology has achieved rigorous regulatory compliance through comprehensive validation processes that meet and exceed industry standards. The platform’s performance has been independently verified through extensive third-party testing and certification programs aligned with EPA, FDA, and international water quality monitoring requirements.

The technology’s validation framework follows a multi-tiered approach that combines laboratory testing, field trials, and real-world implementation studies. In a notable pilot project with a major municipal water utility, FREDsense’s biosensors demonstrated 99.2% accuracy in detecting trace contaminants when measured against standard laboratory methods, while delivering results in minutes rather than days.

A key strength of the validation process lies in the platform’s ability to establish compliance confidence. The biosensors undergo continuous calibration checks and automated quality control measures that ensure reliable performance across varying water conditions and contaminant concentrations. This self-validating capability provides operators with real-time verification of measurement accuracy.

The technology has earned certification from leading industry bodies including NSF International and ISO 17025 accredited laboratories. These certifications validate not only the accuracy of contaminant detection but also the robustness of the platform’s data management system, which maintains detailed audit trails and reporting capabilities essential for regulatory documentation.

Case studies from industrial applications further demonstrate the technology’s compliance advantages. At a mining operation in Western Canada, FREDsense’s continuous monitoring system helped the facility maintain consistent regulatory compliance while reducing manual sampling costs by 60%. The automated early warning capabilities prevented potential discharge violations by detecting anomalies hours before they would have been caught by conventional testing methods.

Beyond meeting current standards, FREDsense’s modular architecture allows for rapid adaptation to evolving regulatory requirements. The platform can be updated to monitor new parameters of concern without requiring complete system replacement, providing a future-proof solution for water quality compliance.

Future Innovations Pipeline

FREDsense’s biological sensor platform continues to evolve with ambitious developments that promise to revolutionize water quality monitoring further. The company’s R&D pipeline focuses on expanding detection capabilities to address emerging contaminants while enhancing the existing technology’s sensitivity and reliability.

A key focus area is the development of new biosensor arrays capable of detecting multiple parameters simultaneously. By engineering novel bacterial strains with heightened sensitivity to specific compounds, FREDsense is creating more comprehensive monitoring solutions. The platform’s expansion includes capabilities for detecting pharmaceuticals, industrial chemicals, and emerging contaminants like PFAS compounds.

Significant advances in the company’s proprietary signal processing algorithms are enabling real-time detection at ever-lower concentrations. These improvements leverage machine learning to filter out environmental noise and enhance measurement accuracy across varying water conditions. The technology roadmap includes integrating advanced data analytics to provide predictive insights about water quality trends and potential contamination events.

Miniaturization efforts are underway to reduce the physical footprint of monitoring units while maintaining or improving performance metrics. This initiative aims to enable more flexible deployment options, from industrial settings to remote monitoring stations. The company is also developing more energy-efficient components to extend deployment duration for battery-powered units.

Perhaps most notably, FREDsense is pioneering automated calibration systems that will significantly reduce maintenance requirements. This advancement builds on research showing how certain bacterial strains can self-regulate their sensitivity, potentially enabling systems that maintain accuracy for extended periods without manual intervention.

Collaboration with research institutions continues to yield promising developments in synthetic biology approaches that could unlock detection capabilities for previously challenging compounds. These partnerships, combined with the company’s internal innovation pipeline, position FREDsense to address tomorrow’s water quality challenges with increasingly sophisticated biological sensing solutions.

Implementation and Support

Adopting FREDsense’s biosensor technology follows a structured implementation pathway designed to ensure smooth integration and long-term success. The process begins with a comprehensive site assessment where FREDsense engineers evaluate the facility’s specific water quality monitoring needs, existing infrastructure, and operational requirements.

A core component of implementation is the intensive training program provided to facility operators and technicians. This hands-on training covers biosensor installation, calibration procedures, data interpretation, and routine maintenance protocols. The program emphasizes practical experience, allowing staff to develop confidence in operating the system under expert guidance.

System integration proceeds in phases, beginning with parallel testing alongside existing monitoring methods to validate performance and establish baseline measurements. FREDsense’s technical team works closely with facility personnel to optimize sensor placement, configure automated sampling procedures, and establish data communication protocols with existing SCADA or control systems.

The transition to full implementation includes 24/7 remote monitoring capabilities and automated alert systems that notify operators of any deviations from established parameters. This proactive approach enables rapid response to potential water quality issues before they become critical problems.

Post-implementation support remains a cornerstone of FREDsense’s service model. Regular system health checks, performance optimization reviews, and software updates ensure the technology continues to operate at peak efficiency. The company maintains dedicated support channels, including emergency technical assistance and scheduled maintenance visits.

As discussed in how to consistently deliver on the promise as a consultant engineer, ongoing success depends on reliable support infrastructure. FREDsense provides comprehensive documentation, troubleshooting guides, and access to an online knowledge base. Additionally, customers receive quarterly performance reports detailing system metrics, trends, and recommendations for optimization.

The implementation process culminates in a thorough review of operational data and establishment of long-term performance benchmarks, setting the stage for continuous improvement and potential system expansion based on evolving needs.

Investment Potential

FREDsense’s innovative biosensor technology for water quality monitoring has positioned the company for significant growth in the environmental technology sector. The startup’s trajectory shows promising financial indicators, with revenue growth exceeding industry averages and expanding market penetration across North America.

The company’s scalable business model leverages a combination of hardware sales and recurring revenue through data analytics services. This dual-stream approach provides both immediate returns and long-term value creation. Market analysis suggests the water quality monitoring segment could reach $4.7 billion by 2025, with biosensor technologies capturing an increasing share.

FREDsense’s expansion strategy focuses on three key areas: geographic diversification into European and Asian markets, vertical integration into new industries beyond municipal water treatment, and continued R&D investment to broaden their sensor portfolio. The company projects a compound annual growth rate of 35% over the next five years, driven by increasing regulatory requirements and growing demand for real-time water quality data.

Investor interest remains strong, with the latest funding round oversubscribed by institutional investors. The company’s intellectual property portfolio, including multiple patents for their biosensor technology, provides significant barriers to entry and enhances long-term value proposition. Strategic partnerships with major water utilities and industrial players have created a robust sales pipeline.

Risk factors include regulatory changes, technology adoption rates, and competition from emerging sensor technologies. However, FREDsense’s established market position and proven technology provide competitive advantages. The company’s focus on operational efficiency and strategic resource allocation suggests strong potential for sustainable growth and attractive returns for investors.

As environmental concerns and water quality regulations become more stringent globally, FREDsense’s market opportunity continues to expand. The company’s ability to provide cost-effective, real-time monitoring solutions positions it well for capturing significant market share in this growing sector.

Final words

FREDsense stands at the forefront of a new era in water quality monitoring, where biological innovation meets technological efficiency. Their unique approach to using genetically modified bacteria as microscopic sensors has proven to be not just a scientific breakthrough, but a practical solution to real-world water quality challenges. As water quality concerns continue to grow globally, FREDsense’s technology offers a scalable, reliable, and cost-effective way to ensure water safety. For water industry professionals, investors, and executives, FREDsense represents more than just another monitoring solution – it’s a paradigm shift in how we approach water quality assurance. The company’s continuous innovation, strong market position, and demonstrated success in real-world applications make it a compelling example of how biotechnology can revolutionize traditional industry practices. As we look to the future of water quality monitoring, FREDsense’s biosensor technology is poised to play an increasingly crucial role in protecting one of our most vital resources.

Get deeper insights into water technology innovations: Subscribe to our weekly newsletter ➡️

About us

We deliver comprehensive coverage of water industry innovations, combining technical expertise with engaging storytelling. Subscribe to our podcast, YouTube channel, and newsletter for unique insights into the evolving water technology landscape.