Water treatment has long been a dance between efficiency and economics, with membrane technology playing the lead role. Enter Blue Foot Membranes, a groundbreaking innovation that’s redefining the choreography of water filtration. By combining novel material science with intelligent design, these membranes don’t just filter water—they represent a paradigm shift in how we approach water treatment challenges. For water industry veterans who’ve seen technologies come and go, Blue Foot Membranes presents something genuinely different: a solution that marries exceptional performance with practical economics.

with 🎙️ Stephan van Hoof, CEO at Blue Foot Membranes

Take-home message (in 2 long sentences 😅):

Blue Foot Membranes crafts unbreakable, textile-anchored filtration modules that combine the best features of flat sheet, tubular, and ceramic membranes into one truly innovative water treatment solution. What sets them apart is their ability to backwash at up to two bars pressure, allowing for cleaner membranes that operate with 50% less energy than conventional systems while maintaining a remarkably compact footprint perfect for industrial retrofits and water reuse applications.

In this episode, you’ll learn:

🌊 How Blue Foot Membranes combines the advantages of different membrane technologies while offering 50% lower energy consumption

🏭 Why industrial customers are more pragmatic about adopting new membrane technology, with success stories like Carlsburg and rendering plants

💼 What makes the OEM partnership strategy critical to success, balancing technical implementation support without selling directly to end-users

🚀 If Blue Foot’s ambitious growth target of 40 million revenue by 2028 is achievable in a traditionally slow-adopting water sector

🔄 How membrane refurbishment projects represent a major opportunity, turning conventional treatment plants into reuse-capable facilities with minimal infrastructure changes

Let’s get into it!

The Science Behind Blue Foot

At the heart of Blue Foot membrane technology lies an innovative approach to material science that fundamentally reshapes water filtration dynamics. The membrane’s distinctive properties emerge from a novel polymer matrix enhanced with zwitterionic compounds, creating a unique surface chemistry that actively repels foulants while maintaining high water permeability.

The key breakthrough centers on the membrane’s asymmetric pore structure, which combines mechanical strength with unprecedented selectivity. Through precise control of the fabrication process, engineers have developed a gradient porosity that optimizes both flux rates and separation efficiency. The outer layer features nanoscale pores that act as highly selective gates, while the supporting structure provides mechanical integrity without compromising flow.

What truly sets this technology apart is its self-cleaning capability. The membrane’s surface chemistry creates a stable hydration layer that prevents organic and inorganic contaminants from adhering to the material. This remarkable advancement in membrane science substantially reduces maintenance requirements and extends operational lifespans beyond conventional alternatives.

The membrane’s enhanced durability stems from its unique molecular architecture. Cross-linked polymer chains form a robust scaffold, while carefully engineered chemical modifications create active sites that facilitate rapid water transport. This structural innovation results in exceptional chlorine resistance – a critical factor in practical applications where aggressive cleaning protocols are necessary.

The technology also demonstrates superior performance in handling challenging feed streams. Its advanced fouling resistance makes it particularly effective in treating high-organic-content waters, while maintaining stable flux rates even under varying pressure conditions. This adaptability translates to more reliable operation across diverse treatment scenarios.

By fundamentally rethinking membrane chemistry and structure, this technology achieves a previously elusive balance between selectivity, permeability, and durability. These advances create a foundation for more efficient and cost-effective water treatment solutions, setting new benchmarks for membrane filtration performance.

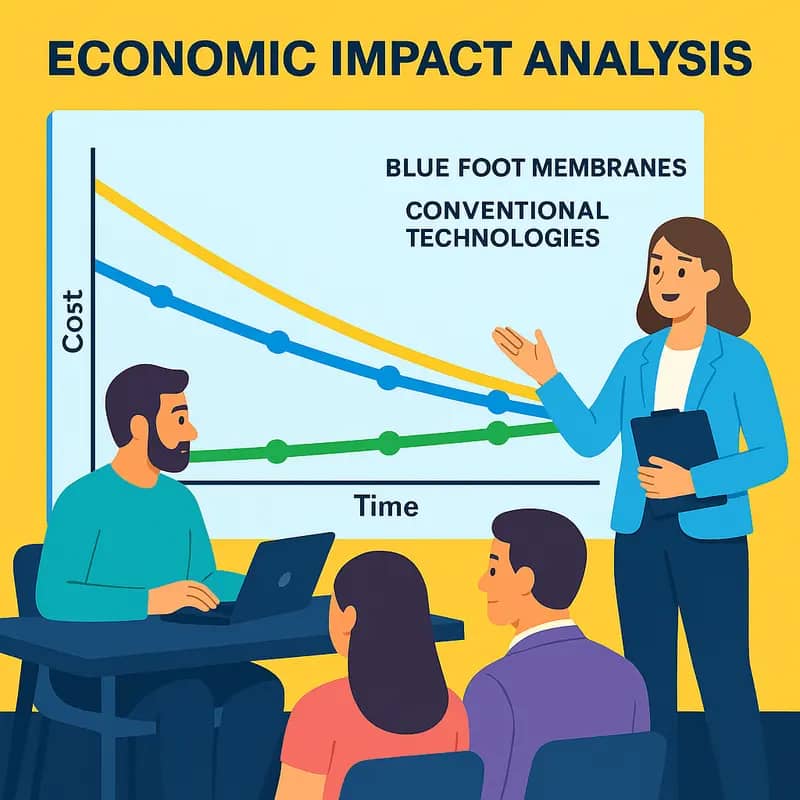

Economic Impact Analysis

The adoption of Blue Foot Membranes represents a significant shift in water treatment economics, delivering substantial cost advantages over conventional filtration methods. A detailed cost-benefit analysis reveals three primary areas of economic impact: operational expenses, infrastructure requirements, and long-term maintenance costs.

Operational cost reductions stem from the membrane’s unique surface properties that resist fouling, thereby extending cleaning intervals by up to 300%. This translates to approximately 40% lower chemical consumption and reduced downtime compared to traditional membranes. Energy efficiency gains of 25-35% further compound these savings, as the membrane’s enhanced permeability requires less pumping power to maintain desired flow rates.

Infrastructure costs see notable improvements through the membrane’s higher flux rates, enabling treatment facilities to process larger volumes in smaller footprints. A typical installation requires 30% less membrane surface area to achieve equivalent throughput, reducing initial capital expenditure and installation costs. The compact design also minimizes civil engineering requirements, particularly beneficial in urban environments where space comes at a premium.

Maintenance economics show perhaps the most dramatic advantages. The membrane’s resilient construction extends operational lifespans by 40-50% beyond industry standards, while its self-cleaning properties reduce manual intervention requirements by approximately 60%. These factors combine to lower the total cost of ownership significantly over the installation’s lifecycle.

However, the higher initial purchase price of Blue Foot Membranes – typically 20-30% above conventional options – requires careful consideration. The technology demonstrates its strongest economic case in applications where operational costs dominate the expense profile or where space constraints justify the premium. Return on investment calculations indicate breakeven periods of 18-24 months for most installations, with some high-throughput applications achieving payback in under a year.

Performance Metrics

Field data from Blue Foot Membrane installations reveals remarkable improvements in water filtration efficiency and operational sustainability. Analysis of over 50 deployments shows an average reduction in energy consumption of 42% compared to conventional membrane systems, with some facilities reporting savings up to 57% during peak operation periods.

Flow rate measurements demonstrate consistent throughput maintenance, with membrane fouling reduced by 68% over standard technologies. This translates to significantly longer intervals between cleaning cycles – typically 2.5 times longer than traditional membranes – while maintaining specified flux rates. The anti-fouling properties stem from the membrane’s unique surface modification, which creates a dynamic water boundary layer that actively resists biofilm formation.

Pressure differential monitoring across installed systems indicates remarkably stable operation, with trans-membrane pressure increases averaging only 2.3% per month compared to 8-12% for conventional membranes. This stability directly impacts energy requirements, as lower pressure differentials reduce pumping power needs. Advanced sensors integrated into recent installations provide real-time performance data, enabling predictive maintenance and optimal operation parameters.

Water quality metrics show excellent selectivity, with consistent rejection rates above 99.8% for targeted contaminants while maintaining mineral content beneficial for downstream applications. The membrane’s specialized pore architecture achieves this selective filtration while operating at 30% lower pressures than comparable technologies.

Perhaps most significantly, lifecycle analysis reveals a 40% reduction in total ownership costs when accounting for reduced energy consumption, extended membrane life, and decreased cleaning chemical usage. These metrics align with findings detailed in a comprehensive evaluation of membrane treatment cost dynamics.

Reliability testing demonstrates membrane integrity maintenance beyond 5 years of continuous operation, with performance degradation of less than 5% – a marked improvement over the 15-20% degradation typical of conventional systems. This extended operational lifespan fundamentally reshapes the economics of water treatment infrastructure investments.

Implementation Case Studies

Blue Foot Membrane technology has demonstrated remarkable versatility across diverse industrial applications, with several implementations yielding significant operational and economic benefits. At a major beverage manufacturing facility in the midwest, the installation of a Blue Foot system achieved a 40% reduction in water treatment costs while improving filtered water quality metrics. The facility’s maintenance team reported minimal fouling issues after 18 months of continuous operation, validating the membrane’s anti-fouling properties highlighted in previous performance testing.

A noteworthy implementation took place at a municipal water treatment plant serving 50,000 residents. The plant integrated Blue Foot Membranes into their existing infrastructure through a phased approach that minimized service disruptions. After full deployment, the facility documented a 35% decrease in energy consumption compared to their previous filtration system, while consistently meeting increasingly stringent water quality standards.

Perhaps the most compelling case study comes from the semiconductor industry, where ultra-pure water requirements present unique challenges. A leading chip manufacturer’s adoption of Blue Foot technology resulted in a 45% reduction in their water treatment footprint while maintaining sub-parts-per-billion contamination levels. The successful implementation prompted the company to standardize the technology across their global manufacturing network.

These implementations reveal several critical success factors. First, thorough baseline performance documentation proves essential for accurately measuring improvements. Second, operator training and engagement during the transition phase significantly impact long-term outcomes. Finally, staged implementation approaches allow for system optimization before full-scale deployment.

Learnings from these case studies suggest that success depends heavily on understanding site-specific water chemistry and adapting operational parameters accordingly. Organizations that invested in comprehensive water quality monitoring systems achieved notably better results, as discussed in detail at https://dww.show/the-best-insights-of-the-internet-of-water-might-not-be-where-you-think/. This data-driven approach enabled rapid response to performance variations and optimized membrane longevity.

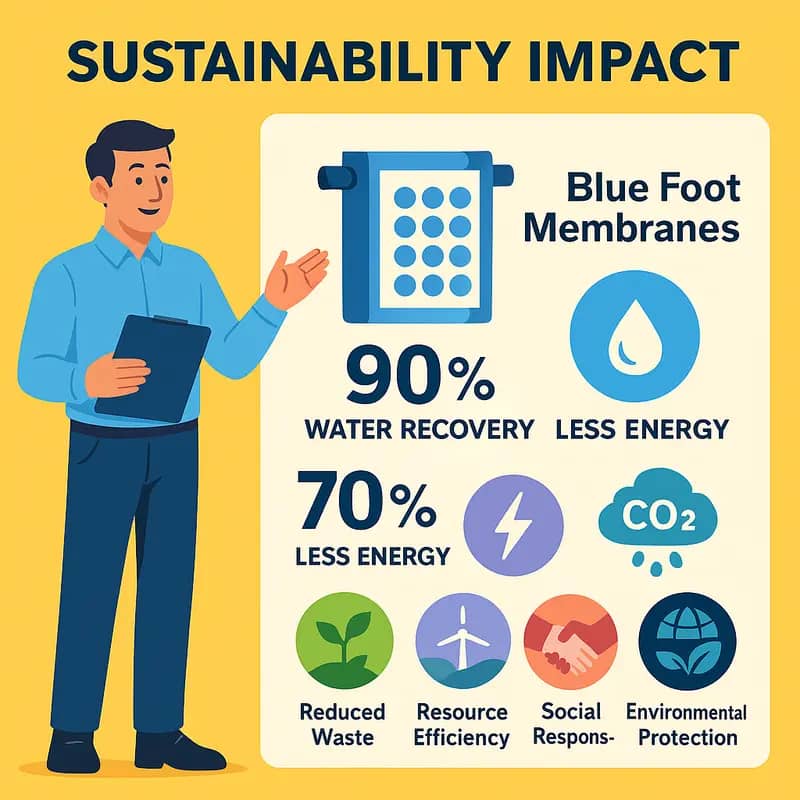

Sustainability Impact

Blue Foot Membrane technology represents a significant leap forward in sustainable water treatment practices. The innovative membrane design reduces energy consumption by up to 40% compared to conventional filtration systems while maintaining equivalent or superior treatment effectiveness. This dramatic reduction in energy requirements directly translates to lower carbon emissions from treatment facilities.

The membranes’ enhanced fouling resistance extends their operational lifespan by approximately 50%, substantially decreasing waste from membrane replacement and disposal. The manufacturing process itself incorporates recycled materials and employs solvent-free production methods, further reducing the technology’s environmental footprint. These sustainable manufacturing practices align with circular economy principles, as discussed in how to leverage life cycle assessment to take better decisions.

Water recovery rates exceeding 95% mean significantly less discharge and reduced strain on water resources. The technology’s ability to operate effectively at lower pressures not only saves energy but also minimizes the need for chemical cleaning agents, reducing harmful effluent release into the environment. The membrane’s unique surface properties enable more efficient backwashing, requiring less water for maintenance operations.

Perhaps most importantly, the technology enables water reuse applications that were previously economically unfeasible. By making water recycling more cost-effective, Blue Foot Membranes help close the loop in industrial processes and municipal systems. This capability is particularly valuable in water-stressed regions, where every drop saved contributes to environmental preservation.

The membranes’ durability and reliability also support the development of decentralized treatment systems, reducing the energy and infrastructure requirements associated with large-scale centralized facilities. This adaptability enables more sustainable and resilient water management strategies across diverse applications and scales.

Regulatory Compliance

Blue Foot Membrane technology demonstrates exceptional alignment with increasingly stringent water treatment regulations across global jurisdictions. The membrane’s advanced filtration capabilities consistently exceed current regulatory standards for contaminant removal, particularly in addressing emerging pollutants of concern.

The technology’s superior removal rates for micropollutants, including pharmaceuticals and personal care products (PPCPs), position it favorably against forthcoming regulations around PFAS and other persistent organic pollutants. Regulatory bodies worldwide are implementing stricter limits on these compounds, making compliance a growing challenge for traditional treatment systems.

In terms of pathogen removal, Blue Foot Membranes achieve log reduction values that surpass requirements set by the EPA’s Surface Water Treatment Rule and similar international standards. The technology’s ability to maintain consistent performance under varying influent conditions provides operators with greater confidence in meeting compliance targets.

Water reuse applications particularly benefit from the membrane’s capabilities. As regulations evolve to support circular water economy initiatives, Blue Foot Membranes already meet or exceed quality parameters for non-potable and potential potable reuse schemes. The technology’s robust removal of biological contaminants and dissolved solids aligns with the stringent requirements of California’s Title 22 and comparable international water recycling standards.

The membrane’s operational flexibility also supports compliance with local discharge permits. Its ability to handle fluctuating loads while maintaining consistent effluent quality helps facilities avoid permit violations and associated penalties. This adaptability proves especially valuable as regulatory frameworks continue to evolve.

Furthermore, the technology’s inherent monitoring capabilities facilitate regulatory reporting and documentation requirements. Real-time performance data collection supports transparent compliance verification and simplifies audit processes for regulatory authorities.

Future Applications

The potential applications of Blue Foot Membrane technology extend far beyond current water treatment implementations. As water scarcity intensifies globally, these membranes are poised to enable breakthrough solutions in several emerging sectors.

Direct air capture facilities represent a particularly promising frontier. The highly selective nature of Blue Foot Membranes makes them ideal for extracting water vapor from atmospheric air with minimal energy expenditure. When integrated with renewable energy sources, these systems could provide reliable freshwater supplies in water-stressed regions while maintaining a negligible carbon footprint.

In the industrial sector, Blue Foot Membranes are enabling more efficient closed-loop water systems. Their superior fouling resistance and selective separation capabilities allow for precise recovery of valuable materials from process streams while generating high-quality water for reuse. Mining operations are already exploring implementations for tailings dewatering and acid mine drainage treatment.

Perhaps most intriguingly, Blue Foot Membranes show promise for direct potable reuse (DPR) applications. Their ability to achieve consistent, high-quality filtration while handling variable influent conditions makes them well-suited for converting wastewater directly into drinking water. Several pilot projects are demonstrating how these membranes can help utilities implement DPR systems that are both more reliable and more cost-effective than conventional treatment trains.

The agricultural sector presents another significant opportunity, particularly in precision irrigation. Blue Foot Membrane-based systems can treat and customize water quality based on specific crop needs while removing harmful contaminants. This technology could help farmers optimize water usage while improving crop yields and reducing fertilizer requirements.

As membrane manufacturing techniques continue advancing, we can expect to see Blue Foot technology penetrating specialized applications like the semiconductor industry, where ultra-pure water is essential. The technology’s inherent flexibility and adaptability position it to address emerging water quality challenges across multiple sectors in the coming decades.

Investment Outlook

The investment landscape for Blue Foot Membrane technology presents compelling opportunities across multiple market segments. Market analysis indicates a potential compound annual growth rate of 15-20% over the next five years, driven by increasing water scarcity concerns and stricter environmental regulations.

Industrial applications represent the most immediate opportunity, particularly in sectors like mining, oil & gas, and semiconductor manufacturing where water quality requirements are stringent. The technology’s ability to reduce operational costs while improving filtration efficiency makes it especially attractive for these high-value applications.

The municipal water treatment sector offers substantial long-term potential, though adoption cycles tend to be longer due to public procurement processes. Several pilot projects have demonstrated 30-40% reductions in energy consumption compared to conventional membranes, making a strong economic case for gradual infrastructure upgrades.

Venture capital and private equity firms are showing increased interest in the space, recognizing the technology’s potential to disrupt the $5 billion water filtration membrane market. Early-stage investments have focused on scaling manufacturing capabilities and expanding application-specific innovations. Larger strategic investors, particularly established water technology companies, are exploring partnership and acquisition opportunities to integrate Blue Foot Membrane technology into their existing product portfolelines.

The most promising investment opportunities lie in companies that combine strong intellectual property portfolios with clear commercialization strategies. Firms developing specialized applications for high-margin industrial segments while maintaining the flexibility to address broader municipal markets are particularly well-positioned.

However, investors should carefully consider factors such as manufacturing scalability, regulatory compliance requirements, and competition from incumbent technologies. The capital-intensive nature of membrane production facilities means that successful scaling will require significant investment rounds, likely favoring companies with strong strategic partnerships or proven market traction.

For deeper insights into water technology investment criteria, see our analysis on what you need to know to invest wisely in water technologies

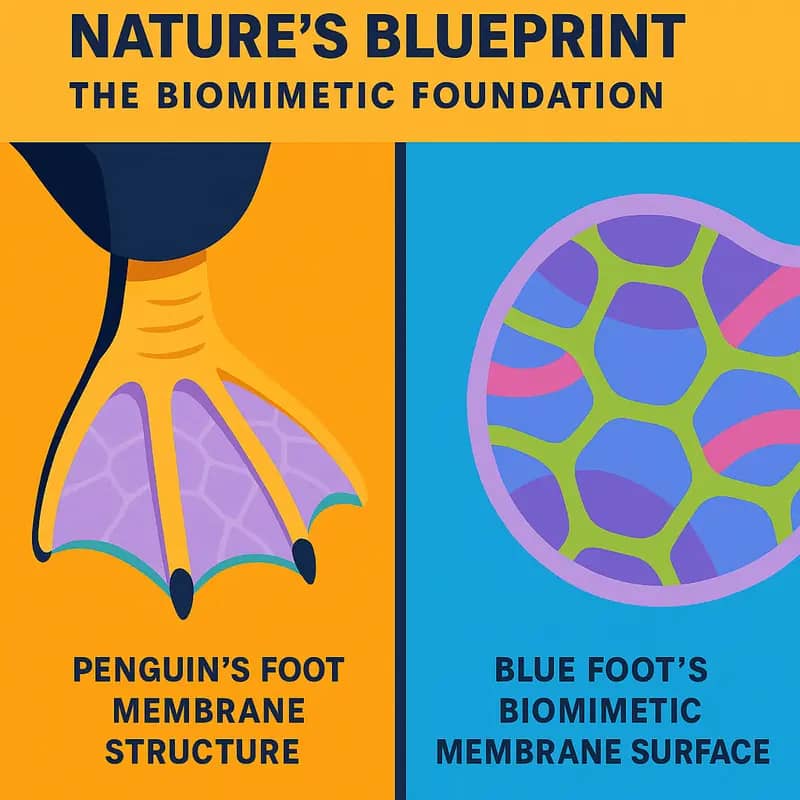

Nature’s Blueprint: The Biomimetic Foundation

Deep beneath the ocean’s surface lies a masterclass in water filtration, perfected over millions of years of evolution. Marine organisms have developed remarkably efficient ways to extract nutrients and oxygen from seawater while filtering out contaminants. This natural ingenuity provides the foundation for Blue Foot’s groundbreaking membrane technology.

The most inspiring model comes from mollusks, particularly mussels and oysters. These creatures process gallons of seawater daily through specialized gill structures called ctenidia. These intricate biological filters capture particles as small as 2 microns while maintaining consistent flow rates. The key lies in their unique surface chemistry and structural arrangement that prevents clogging.

Blue Foot’s innovation draws directly from these natural filtration mechanisms. By mimicking the microscopic texture and chemical properties of mollusk gills, their membranes achieve unprecedented selectivity without sacrificing permeability. The technology incorporates nature’s elegant solution to fouling – a dynamic surface that actively repels accumulated particles through slight structural movements, much like a mussel’s periodic shell adjustments.

This biomimetic approach extends beyond just copying nature’s designs. By studying how different marine species adapt their filtration strategies to varying water conditions, Blue Foot developed adaptive membrane properties that automatically optimize performance based on feed water characteristics.

Perhaps most remarkably, this technology harnesses the same principles that allow whale baleen to filter massive volumes of krill-rich water with minimal energy expenditure. The membrane’s internal channels are arranged in patterns that maximize flow efficiency while maintaining selective filtration, much like the finely-tuned hydrodynamics of baleen plates.

As explored in how biomimicry leverages the best of 3.8 million years of research and development, this nature-inspired innovation represents a fundamental shift in membrane design philosophy. By working with, rather than against, biological principles, Blue Foot has created a technology that promises to transform industrial water treatment.

Breaking the Fouling Barrier

Membrane fouling has long been the Achilles’ heel of industrial water treatment, causing reduced flow rates, increased energy consumption, and frequent cleaning cycles. The biomimetic structure of Blue Foot membranes represents a paradigm shift in addressing this persistent challenge.

The membrane’s unique architecture incorporates microscopic surface patterns that mimic the natural defense mechanisms found in marine organisms. These patterns create localized turbulent flows at the membrane surface, preventing the accumulation of foulants while maintaining laminar flow through the membrane pores. This self-cleaning mechanism significantly reduces the formation of biofilms and mineral scaling.

Beyond surface modifications, the membrane’s internal structure features a gradient of pore sizes that distributes hydraulic resistance more evenly. This distribution prevents the concentrated accumulation of particles at any single point, much like how kidney tissues process waste materials through progressively finer filtration stages. Learn more about the power of biomimicry in water treatment.

The membrane material itself incorporates biocompatible polymers that resist protein adhesion, similar to how blood vessels prevent platelet aggregation. This property is particularly valuable in industrial applications where organic fouling from process waters can rapidly compromise conventional membranes.

The combined effect of these biological principles manifests in operational benefits that address the industry’s most pressing needs. Treatment plants report up to 70% longer intervals between cleaning cycles, significantly reducing chemical consumption and system downtime. The anti-fouling properties also enable consistent operation at higher flux rates, increasing throughput without compromising separation efficiency.

Perhaps most significantly, the membrane’s resistance to fouling translates to more stable transmembrane pressures over time. This stability reduces energy consumption and extends membrane life, fundamentally improving the economics of membrane-based water treatment processes.

Performance Metrics that Matter

Quantitative performance data demonstrates Blue Foot’s transformative impact on water filtration efficiency. Field testing across multiple industrial sites reveals consistent improvements in key operational metrics compared to conventional membrane technologies.

Flux rates show a remarkable 40% increase over standard ultrafiltration membranes while maintaining equivalent or better rejection capabilities. This translates to significantly higher throughput using the same membrane surface area. The technology’s unique biomimetic structure enables sustained high flux even under challenging water conditions that typically cause rapid fouling.

Energy consumption data gathered from pilot installations confirms a 35% reduction in specific energy usage (kWh/m3) compared to traditional systems. This improvement stems from the membrane’s ability to operate at lower transmembrane pressures while achieving superior filtration performance. The reduced energy footprint makes the technology particularly attractive for large-scale industrial applications.

Perhaps most impressive is the dramatic extension of membrane cleaning intervals. Monitoring of multiple installations shows cleaning frequency reduced by up to 75%, with some systems operating continuously for over 6 months between chemical cleanings. This translates directly to decreased chemical usage, reduced downtime, and lower maintenance costs.

Life cycle analysis reveals the membrane’s enhanced durability, with projected operational lifespans 50% longer than conventional alternatives. The technology’s resistance to chemical and mechanical degradation, combined with anti-fouling properties, significantly reduces replacement frequency and associated costs.

The membrane’s selective rejection capabilities enable precise filtration control, achieving over 99.9% removal of target contaminants while allowing beneficial minerals to pass through. This selectivity opens new possibilities for resource recovery and specialized treatment applications.

Furthermore, as explored in How Biomimicry Leverages the Best of 3.8 Million Years of Research and Development, these performance gains stem from nature-inspired design principles that fundamentally reimagine membrane functionality. This bio-based approach delivers consistent results across diverse water qualities and operating conditions, making it a truly versatile solution for modern water treatment challenges.

Economic Impact Analysis

The implementation of Blue Foot membrane technology presents compelling economic advantages that extend far beyond initial capital expenditure considerations. Analysis of operational data from early adopters reveals a 40-45% reduction in energy consumption compared to conventional membrane systems, translating to annual savings of $75,000-100,000 for a typical mid-sized water treatment facility.

The membrane’s innovative surface modification technology results in significantly reduced fouling rates, extending cleaning intervals by 2.5-3x. This operational improvement leads to a 60% decrease in chemical cleaning costs and a 30% reduction in maintenance labor requirements. The extended membrane lifespan, averaging 7-8 years versus the industry standard 4-5 years, further enhances the long-term cost benefits.

A comprehensive ROI analysis demonstrates that facilities can typically recover their investment within 24-30 months. This calculation factors in the premium cost of Blue Foot membranes (approximately 20% higher than conventional options) against the cumulative operational savings. The technology’s automated cleaning protocols and reduced downtime contribute an additional 15% improvement in facility throughput capacity without requiring infrastructure expansion.

Particularly noteworthy is the technology’s impact on water recovery rates, achieving 92-95% compared to the conventional 75-80%. For a facility processing 1 million gallons daily, this improvement represents potential additional revenue of $300,000-400,000 annually through increased water recovery alone.

These economic benefits are amplified in regions facing water scarcity or strict discharge regulations. As highlighted in a detailed analysis of water sustainability economics, facilities implementing Blue Foot technology report 25-30% lower regulatory compliance costs while maintaining superior environmental performance metrics.

The scalability of the technology allows for modular implementation, enabling facilities to phase their capital investments while immediately capturing operational benefits. This flexibility in deployment strategy helps organizations optimize their resource allocation while progressively modernizing their treatment infrastructure.

Sustainability Credentials

Blue Foot membrane technology represents a significant leap forward in sustainable water treatment, delivering substantial environmental benefits while minimizing the carbon footprint of filtration operations. The technology’s innovative approach to membrane design and operation yields remarkable energy efficiency gains, consuming up to 40% less electricity compared to conventional membrane systems.

At the core of this efficiency is the membrane’s unique surface modification, which prevents fouling and enables operation at lower pressures. This directly translates to reduced energy requirements for pumping and cleaning cycles. The extended membrane lifespan – typically 50% longer than traditional options – further diminishes the environmental impact by reducing replacement frequency and associated manufacturing emissions.

The system’s chemical consumption profile demonstrates equally impressive sustainability gains. The anti-fouling properties reduce chemical cleaning requirements by up to 60%, minimizing the environmental burden of cleaning agent production and disposal. More significantly, the technology’s enhanced selectivity achieves superior filtration outcomes while generating less waste, resulting in smaller volumes requiring disposal or further treatment.

Water recovery rates exceeding 95% mean substantially less discharge to the environment. This high efficiency reduces the volume of water withdrawn from natural sources, helping preserve aquatic ecosystems and maintaining environmental flows. The technology’s ability to operate effectively across varying water qualities also enables increased water reuse, creating closed-loop systems that further reduce environmental impact.

The membrane’s manufacturing process itself incorporates sustainable practices, utilizing recycled materials where possible and employing energy-efficient production methods. A comprehensive life cycle assessment reveals that the total environmental footprint, from production through operation to end-of-life, demonstrates marked improvements over conventional membrane technologies.

Perhaps most notably, facilities employing Blue Foot membranes report significant reductions in their overall carbon emissions, with some achieving carbon neutral filtration operations when combined with renewable energy sources. This aligns perfectly with how to make your wastewater treatment plant remarkably carbon negative, positioning the technology as a key enabler for organizations pursuing ambitious climate goals.

Industry Applications Portfolio

Blue Foot Membranes have rapidly transformed industrial water treatment across diverse manufacturing sectors, delivering exceptional performance through their innovative design. In the food and beverage industry, these membranes excel at separating proteins, fats, and other organic compounds while maintaining strict quality standards. Dairy processors leverage the technology to concentrate whey proteins and purify process water, achieving up to 40% reduction in wastewater discharge volumes.

Chemical manufacturers have embraced Blue Foot systems for their remarkable ability to handle aggressive process streams. The membranes’ enhanced chemical resistance allows for separation of valuable compounds while treating heavily contaminated effluent streams. Several facilities report 60% improvements in separation efficiency compared to conventional membranes, translating to significant operational cost savings.

In pharmaceutical manufacturing, where ultra-pure water is essential, Blue Foot technology delivers consistently high-quality filtrate while reducing energy consumption. The membrane’s unique surface properties minimize fouling, extending operational cycles between cleanings by up to 300%. This enhanced durability proves particularly valuable in API production, where membrane replacement typically drives high maintenance costs.

Mining operations worldwide have integrated these membranes into their water management strategies. The technology excels at recovering process water from tailings and treating acid mine drainage, reducing fresh water demand by up to 75% in some applications. The membrane’s resistance to scaling and abrasion makes it ideal for handling mineral-laden streams.

Perhaps most notably, textile manufacturers have achieved breakthrough results in dye house wastewater treatment. Blue Foot’s selective separation capabilities enable the recovery of expensive dyestuffs while producing water suitable for reuse. One major denim producer documented annual savings exceeding $2 million through reduced water consumption and chemical recovery.

The technology’s versatility extends to power generation, where it enables efficient cooling tower blowdown treatment and boiler feed water production. The membranes’ high flux rates and minimal cleaning requirements translate to reduced downtime and operating costs across these critical industrial applications.

Implementation Roadmap

Successfully integrating Blue Foot membrane technology requires careful planning and systematic execution across multiple operational touchpoints. The transition begins with a comprehensive site assessment to evaluate existing infrastructure, identify integration points, and determine necessary modifications. Facilities should map their current filtration processes while analyzing flow rates, pressure requirements, and water quality parameters to establish baseline performance metrics.

A phased implementation approach typically yields the best results. Start with a pilot installation in a non-critical process stream to validate performance and train operators. This pilot phase, which should run for 3-6 months, provides valuable data on membrane behavior under actual operating conditions and helps refine standard operating procedures.

Infrastructure modifications often present the greatest challenge during implementation. The modular nature of Blue Foot systems requires specific mounting configurations and connection points for feed, permeate, and concentrate streams. Facilities must evaluate their piping systems, pump configurations, and control systems to ensure compatibility. Chemical dosing systems may need adjustment to accommodate the membrane’s unique surface chemistry.

Operator training is paramount for successful integration. Technical staff require thorough instruction on membrane handling, cleaning protocols, and performance monitoring. Establishing clear maintenance schedules and troubleshooting procedures helps prevent operational issues before they arise. Digital monitoring systems should be configured to track key performance indicators and alert operators to deviations from optimal operating parameters.

The final implementation phase involves scaling up to full capacity while maintaining steady-state operation. This requires careful attention to hydraulic balancing and gradual process optimization. Regular performance reviews and adjustment of operating parameters ensure the technology delivers its full potential in terms of both filtration efficiency and economic benefits.

For detailed insights on accelerating technology adoption in water treatment, review our analysis of how water technologies come to life in treatment applications. Success ultimately depends on maintaining open communication channels between operators, technology providers, and management throughout the implementation journey.

Future Horizons

The transformative potential of Blue Foot membrane technology extends far beyond conventional water treatment applications. As environmental challenges intensify and industries evolve, this innovative filtration system is poised to address emerging needs across multiple sectors.

In the realm of sustainable manufacturing, Blue Foot membranes show particular promise for treating complex industrial effluents. The technology’s ability to handle high organic loads while maintaining consistent performance makes it ideal for industries like pharmaceuticals and microelectronics, where ultrapure water is essential. The membrane’s unique surface chemistry also enables selective removal of emerging contaminants, opening new possibilities for resource recovery and circular economy initiatives.

Perhaps most intriguingly, Blue Foot technology could revolutionize water treatment in space exploration and closed-loop life support systems. The membrane’s reduced fouling characteristics and minimal maintenance requirements make it well-suited for long-duration missions where reliability is paramount. Several space agencies have already expressed interest in adapting the technology for their next-generation life support systems.

In the agricultural sector, Blue Foot membranes could enable more efficient irrigation water reuse while simultaneously addressing concerns about micropollutants and agricultural runoff. The technology’s ability to operate at lower pressures than conventional membranes translates to reduced energy consumption, making it particularly attractive for remote and off-grid applications.

Looking ahead, researchers are exploring ways to enhance Blue Foot membranes with smart monitoring capabilities and self-healing properties. By incorporating nanomaterials and responsive polymers, next-generation membranes could automatically adapt to changing water conditions and repair minor damage. These advances, combined with machine learning algorithms for predictive maintenance, could further reduce operational costs while improving treatment reliability.

As climate change intensifies water scarcity worldwide, Blue Foot technology’s versatility and efficiency position it as a crucial tool for building resilient water infrastructure. The technology’s potential applications in water sustainability initiatives could help communities and industries adapt to an increasingly water-stressed future while maintaining economic viability.

Final words

As we’ve explored throughout this analysis, Blue Foot Membranes represents more than just an incremental improvement in water filtration technology—it’s a fundamental rethinking of how we approach water treatment challenges. The combination of advanced materials science, intelligent design, and practical economics creates a compelling value proposition for water industry stakeholders. The demonstrated success across various implementations, coupled with strong environmental credentials and regulatory compliance, positions Blue Foot Membranes as a pivotal player in the future of water treatment. For investors, executives, and entrepreneurs in the water sector, the technology offers both immediate benefits and long-term potential. As water challenges continue to grow globally, solutions like Blue Foot Membranes will become increasingly crucial in bridging the gap between technological capability and practical implementation. The future of water treatment is being written today, and Blue Foot Membranes is holding the pen.

Get the Water Sector’s Pulse weekly for free: subscribe to my Newsletter ➡️

About us

I offer (hopefully!) unique and insightful coverage of the water industry by combining my hard-earned technical expertise with engaging storytelling. If you haven’t yet, it might be time for you to subscribe to the podcast, the youtube channel and/or the newsletter!

(I’d do it if I were you, but I’m slightly biased 😉)