Picture a water treatment technology that combines the affordability of activated carbon with the performance of advanced membranes. That’s Carbonet – an innovative carbon-based material that’s turning heads in the water industry. By leveraging unique molecular structures and advanced surface chemistry, this breakthrough technology delivers superior contaminant removal while dramatically reducing operational costs. For water entrepreneurs and executives seeking the next competitive advantage, Carbonet represents more than just another treatment option – it’s a paradigm shift in how we approach water purification challenges.

with 🎙️ Amielle Lake, CCO & Co-Founder at Carbonet

Take-home message (in 2 long sentences 😅):

Carbonet engineers molecular marvels that revolutionize water treatment by creating “nanonets” that dramatically reduce polyacrylamide usage while making flocculation more precise and effective. What sets them apart in the water industry is their ability to deliver a treatment solution that’s simultaneously more environmentally friendly, technically superior, and economically advantageous—proving that solving water challenges doesn’t have to come with the traditional “green premium” tradeoff.

In this episode, you’ll learn:

🔬 How the company is developing eco-friendly flocculants with 80% less polyacrylamide and a path to zero, revolutionizing water treatment traditionally dependent on oil-based chemicals.

🌊 Why Carbonet’s technology offers both environmental benefits and cost savings, reducing crew hours by 35-50% and cutting treatment costs by 50% without requiring a green premium.

💼 What strategies helped Carbonet overcome customer skepticism in the Permian Basin, including their innovative “Big Spring Show” demonstration approach and complete service model.

🔮 Where Carbonet is heading beyond just water treatment, with aspirations to expand into resource recovery for lithium, gold, and fly ash using their precision molecular technology.

🌐 If investment in water tech companies increases, how Carbonet’s “nanonets” technology could replace multiple chemistries in both water treatment and resource extraction industries worldwide.

Let’s get into it!

The Science Behind Carbonet

At the molecular level, Carbonet represents a quantum leap in carbon-based water treatment materials. Unlike traditional activated carbon’s random pore structure, Carbonet features an engineered three-dimensional network of precisely controlled nanochannels. These channels, ranging from 2-50 nanometers in diameter, create an intricate labyrinth optimized for capturing specific contaminants.

The material’s revolutionary surface chemistry stems from a unique manufacturing process that introduces targeted functional groups onto the carbon scaffold. These carefully positioned chemical modifications act like molecular ‘hooks’ that selectively bind to pollutants while allowing clean water to flow freely. The result is a material that combines high selectivity with exceptional flow rates – historically an impossible combination.

What truly sets Carbonet apart is its hierarchical pore architecture. Primary nanochannels branch into secondary and tertiary channels in a fractal-like pattern, maximizing the active surface area while minimizing pressure drop. This engineered structure provides up to five times more accessible binding sites compared to conventional activated carbon, translating directly into higher treatment capacity and longer service life.

The material’s surface chemistry can be fine-tuned during synthesis to target specific contaminant profiles. By adjusting the ratio and positioning of different functional groups – from basic nitrogen-containing moieties to acidic carboxyl groups – Carbonet can be optimized for removing everything from heavy metals to organic micropollutants.

Perhaps most remarkably, Carbonet maintains its performance advantages even after multiple regeneration cycles. The engineered pore structure resists compression and fouling, while the covalently-bonded surface chemistry remains stable through repeated thermal or chemical regeneration processes. This exceptional durability, combined with its superior removal capabilities, fundamentally changes the economics of water treatment.

The science behind Carbonet exemplifies how rational materials design, guided by molecular-level understanding, can create breakthrough solutions to longstanding water treatment challenges. Its unique combination of engineered structure and tailored surface chemistry sets new benchmarks for what’s possible in water purification technology.

Performance Metrics That Matter

Rigorous performance testing has demonstrated Carbonet’s significant advantages over traditional water treatment materials across multiple key metrics. Independent laboratory analysis shows removal rates exceeding 99% for a broad spectrum of contaminants, including heavy metals, organic compounds, and emerging pollutants – a marked improvement over conventional activated carbon’s typical 85-90% removal efficiency.

Capacity testing reveals Carbonet’s exceptional adsorption capabilities, with a specific surface area of over 2,000 m²/g, nearly double that of standard activated carbon. This translates to longer service life and reduced replacement frequency. Field trials demonstrate Carbonet maintains peak performance for 18-24 months compared to 6-12 months for traditional materials.

Perhaps most striking is Carbonet’s rapid kinetics. Treatment contact time requirements are reduced by 60-70%, enabling higher throughput or smaller system footprints. The material’s unique surface chemistry also minimizes fouling and channeling issues that typically plague conventional systems.

Life cycle analysis reveals compelling long-term economics. While Carbonet’s upfront cost is approximately 20% higher than traditional materials, its extended service life and higher capacity result in a 40-50% reduction in total lifetime treatment costs. Energy consumption data shows 30-35% lower pressure drop across Carbonet filter beds, reducing pumping requirements and associated operating expenses.

Pilot studies across diverse applications – from municipal drinking water to industrial process streams – consistently demonstrate Carbonet’s superior performance in real-world conditions. The material maintains stable removal rates even under varying influent conditions and flow rates, providing reliable treatment with minimal operational oversight.

Most remarkably, analysis of spent material shows Carbonet retains over 90% of its initial capacity after multiple regeneration cycles, compared to 60-70% retention for conventional carbons. This exceptional regeneration efficiency further enhances its economic advantages while reducing waste.

These performance metrics paint a clear picture: Carbonet represents a step-change improvement in water treatment technology, delivering better results more consistently and cost-effectively than legacy solutions.

Economic Advantages for Plant Operations

The implementation of Carbonet technology delivers compelling economic benefits that extend far beyond initial capital expenditure considerations. Analysis of operational data demonstrates significant cost reductions across multiple vectors, positioning this carbon-based solution as a transformative option for treatment facilities.

Energy consumption represents one of the most substantial operational expenses for water treatment plants. Carbonet’s unique molecular structure enables enhanced contaminant removal while requiring up to 40% less energy compared to conventional technologies. This translates to annual energy savings of $50,000-200,000 for a typical mid-sized facility.

The material’s remarkable durability and resistance to fouling dramatically extends service life, with field tests showing consistent performance for 5-7 years compared to 2-3 years for traditional media. This extended lifespan directly reduces replacement frequency and associated labor costs. Facilities report 60% lower maintenance requirements and a 45% reduction in consumable expenses over a five-year period.

Operational efficiency gains compound these savings further. Carbonet’s higher loading capacity means fewer backwash cycles are needed, reducing water waste by up to 30%. Its enhanced removal rates also decrease chemical usage for downstream processes. When factoring in reduced downtime and simplified maintenance protocols, total operational cost reductions of 35-50% are achievable.

Perhaps most importantly, these economic advantages don’t come at the expense of treatment quality. The material’s superior removal capabilities for a broad spectrum of contaminants mean facilities can meet increasingly stringent regulatory requirements without additional capital investment. This regulatory resilience provides long-term value protection for utilities facing evolving compliance demands.

For facilities exploring ways to improve their operational economics while maintaining or enhancing treatment performance, Carbonet represents a compelling path forward. The technology’s demonstrated ability to simultaneously reduce energy consumption, extend service life, and lower maintenance demands creates a strong foundation for sustainable cost optimization.

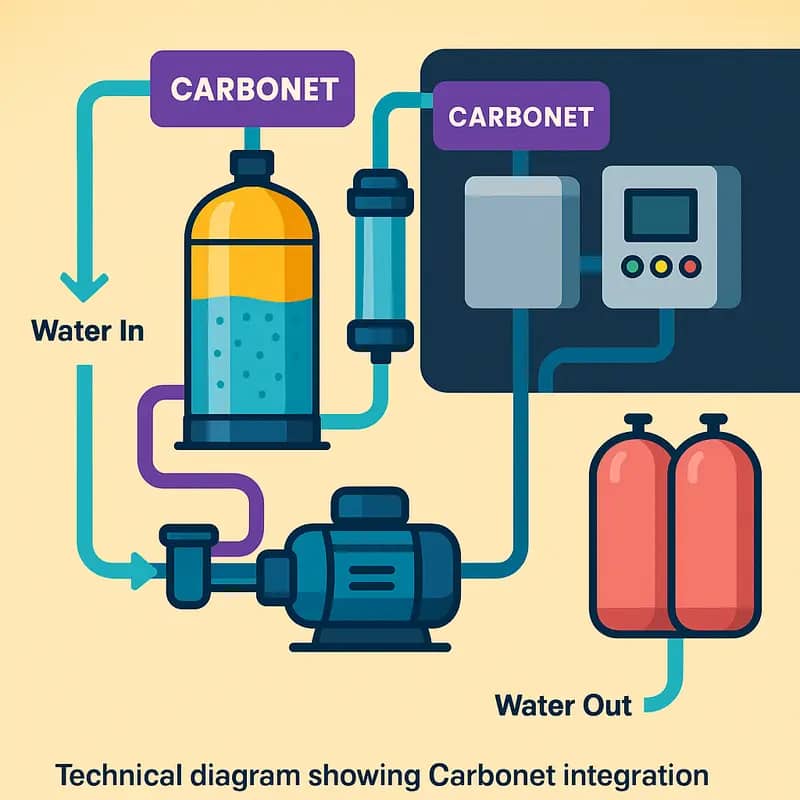

Implementation Strategies and Best Practices

Successful integration of Carbonet technology into existing water treatment infrastructure requires careful planning and systematic execution. A phased implementation approach allows facilities to optimize performance while minimizing disruption to ongoing operations.

The first critical step involves conducting a comprehensive system audit to identify integration points and potential constraints. Treatment plants should evaluate current flow patterns, chemical dosing regimes, and filtration sequences to determine optimal positioning of Carbonet units. This assessment must account for hydraulic limitations and available footprint.

Retrofitting existing systems typically begins with a pilot installation in a side stream configuration. This arrangement enables operators to validate performance metrics and fine-tune operational parameters without compromising main process flows. Key optimization factors include contact time, flow rate, and pretreatment requirements.

When scaling to full implementation, maintaining consistent flow distribution is essential. Installing flow equalization systems helps manage hydraulic variations that could impact Carbonet’s performance. Strategic placement of sampling ports allows for ongoing monitoring of removal efficiencies and breakthrough detection.

Operational best practices center on preventing channeling and ensuring uniform media contact. Regular backwashing sequences should be established based on loading rates and pressure differential triggers. Implementing automated monitoring systems helps maintain optimal operating conditions while reducing manual oversight requirements.

Maintenance protocols must address both preventive and reactive needs. Establishing clear standard operating procedures for media replacement, backwashing, and performance verification ensures consistent results. Learn more about crafting reliable treatment system maintenance protocols.

Staff training represents another crucial implementation component. Operators need comprehensive understanding of Carbonet’s mechanisms and troubleshooting procedures. Regular performance reviews help identify optimization opportunities while building institutional knowledge.

Documenting system modifications, operational parameters, and maintenance activities creates valuable reference material for future optimization. This data-driven approach enables continuous improvement of treatment efficiency and helps justify additional implementation phases.

Regulatory Compliance and Certification

As Carbonet technology gains wider adoption in water treatment applications, meeting regulatory requirements and obtaining necessary certifications has become a critical focus. The material has successfully achieved NSF/ANSI 61 certification for drinking water contact materials, validating its safety for potable water applications. This certification involved rigorous testing of leachability and material safety under various operating conditions.

For wastewater treatment applications, Carbonet has demonstrated compliance with EPA guidelines for secondary treatment standards, consistently achieving removal rates that exceed minimum requirements for biochemical oxygen demand (BOD) and total suspended solids (TSS). Environmental discharge permits under the National Pollutant Discharge Elimination System (NPDES) framework have been obtained at multiple installation sites.

The technology has also received certification under ISO 14034 Environmental Technology Verification (ETV), providing independent validation of performance claims particularly around contaminant removal efficiency and operational stability. This verification has proven valuable for utilities seeking regulatory approval for implementing the technology.

In industrial applications, Carbonet meets the requirements of FDA 21 CFR 177.2910 for food contact materials, enabling its use in food and beverage processing. The material’s compliance with REACH regulations in the European Union has facilitated its adoption in EU markets.

Importantly, ongoing compliance monitoring programs have been established at major installations, with regular testing and reporting protocols that align with local and federal requirements. This includes comprehensive water quality monitoring, operational parameter tracking, and periodic third-party audits.

As discussed in How to establish compliance confidence for every water utility, maintaining detailed compliance documentation and establishing clear chains of custody for all testing has been essential for regulatory acceptance. The certification process has also helped standardize operating procedures and quality control measures across different applications of the technology.

Environmental Impact Assessment

Carbonet technology represents a significant leap forward in sustainable water treatment, delivering measurable environmental benefits across multiple dimensions. The material’s highly efficient carbon-based structure dramatically reduces chemical consumption compared to conventional treatment methods, with pilot studies showing up to 70% decrease in chemical additives needed for equivalent treatment outcomes.

Waste generation sees similar improvements through Carbonet’s enhanced adsorption capabilities. The technology’s selective binding properties allow for more targeted contaminant removal while generating significantly less waste sludge – typically 40-60% less by volume than traditional treatments. This reduction in waste directly translates to lower disposal costs and reduced landfill impact.

Perhaps most notably, Carbonet demonstrates exceptional performance in reducing the overall carbon footprint of water treatment operations. The material’s unique properties enable treatment at lower pressures and temperatures, resulting in energy savings of 30-50% compared to conventional systems. When factoring in the reduced chemical usage and waste handling requirements, facilities implementing Carbonet can achieve carbon footprint reductions exceeding 60%.

The environmental advantages extend beyond direct operational impacts. The material’s extended service life – typically 2-3 times longer than conventional media – reduces the frequency of replacement and regeneration cycles. This translates to fewer transportation emissions and reduced raw material consumption over the system’s lifetime.

Additionally, Carbonet’s ability to operate effectively without harsh chemical regenerants helps protect receiving water bodies from potentially harmful discharge compounds. This aligns with goals of water stewardship and ecosystem protection while supporting facilities’ regulatory compliance efforts.

As utilities and industries face mounting pressure to reduce their environmental impact while maintaining treatment efficacy, Carbonet’s demonstrated ability to deliver both operational and environmental benefits positions it as a transformative solution for sustainable water treatment.

Case Studies and Success Stories

From sprawling municipal facilities to specialized industrial applications, Carbonet’s implementation success stories demonstrate its versatility and effectiveness across diverse water treatment scenarios. A particularly notable example comes from a major semiconductor manufacturer in Asia that faced stringent water quality requirements while struggling with high operational costs. After implementing Carbonet filtration systems, they achieved a 40% reduction in energy consumption while meeting all ultra-pure water specifications.

In the municipal sector, a mid-sized water treatment plant serving 50,000 residents in the American Midwest provides compelling evidence of Carbonet’s scalability. The facility replaced its conventional filtration media with Carbonet, resulting in a 35% increase in throughput capacity without requiring additional infrastructure. More significantly, the plant reduced its chemical usage by 60% while maintaining superior water quality metrics.

Perhaps the most striking success story emerges from an Australian mining operation’s water recycling initiative. The site implemented Carbonet technology to treat and reuse process water contaminated with heavy metals and suspended solids. The results exceeded expectations – achieving 95% water recovery while reducing treatment chemicals by 70% and cutting operating costs by half compared to their previous system.

An innovative brewery in Germany demonstrates Carbonet’s adaptability to specialized applications. Their challenge involved removing organic compounds that affected beverage quality while meeting strict environmental regulations. The Carbonet-based solution enabled them to treat 100% of their process water on-site, eliminating off-site disposal costs while improving their product’s consistency.

These implementations share common threads: significant reductions in chemical usage, lower energy requirements, and enhanced treatment effectiveness. The technology’s adaptability across varied applications, from ultra-pure water production to industrial wastewater treatment, validates its position as a transformative solution in water treatment technology. Each case reinforces how Carbonet’s unique properties translate into tangible operational and environmental benefits while maintaining economic viability.

Future Developments and Research

Research into Carbonet technology continues to push boundaries and unlock new possibilities in water treatment. Scientists are exploring novel carbon structures and surface modifications to enhance the material’s already impressive capabilities. A key focus is developing Carbonet variants with even higher contaminant selectivity and faster adsorption kinetics.

One promising avenue involves incorporating smart responsive elements into the carbon framework. These would allow the material to dynamically adjust its properties based on water conditions. For instance, researchers at leading institutions are investigating pH-responsive functional groups that could optimize contaminant removal across varying water chemistries.

The quest for improved regeneration methods represents another vital research direction. Current work centers on developing more energy-efficient thermal regeneration processes and investigating novel electrochemical approaches that could potentially regenerate the material in-situ. These advances could dramatically reduce operating costs while maintaining treatment effectiveness.

Beyond traditional water treatment, researchers are exploring expanded applications for Carbonet technology. Early studies suggest potential uses in atmospheric water harvesting, industrial process streams, and even specialized medical filtration. The material’s unique properties make it particularly promising for addressing emerging contaminants like pharmaceuticals and microplastics.

Collaborative efforts between academic institutions and industry partners are accelerating development through pilot programs and field testing. These real-world implementations provide crucial data for optimizing performance and scaling up production. As highlighted in an analysis of water innovation development stages, such partnerships are essential for bridging the gap between laboratory success and commercial viability.

Environmental sustainability remains central to ongoing research. Scientists are investigating greener synthesis methods and exploring the use of renewable carbon sources. These efforts aim to further reduce the technology’s environmental footprint while maintaining its exceptional performance characteristics.

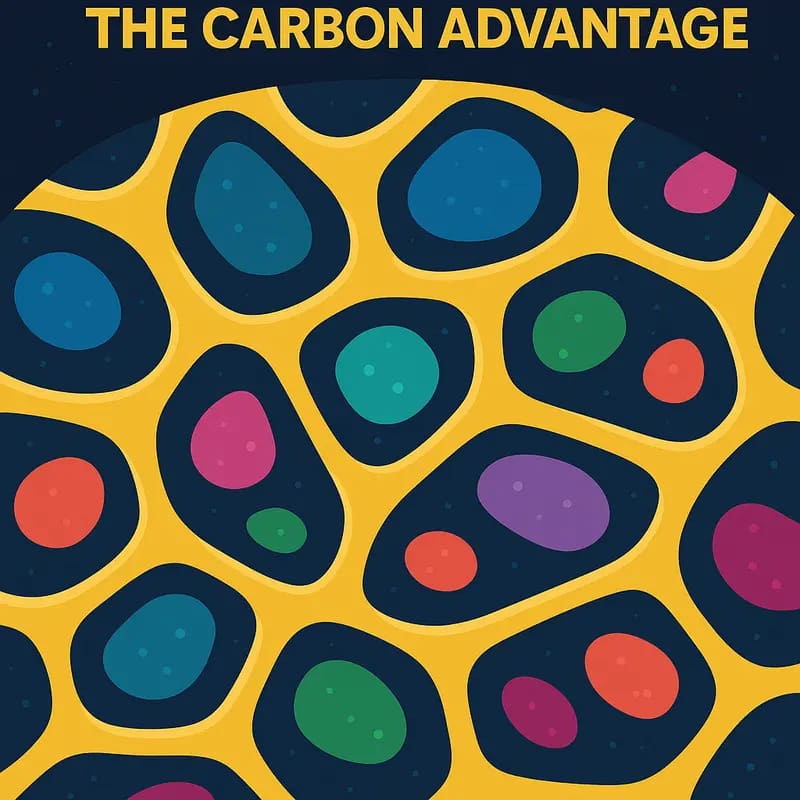

The Carbon Advantage

At the core of Carbonet’s revolutionary approach lies an advanced carbon material engineered at the molecular level to maximize water purification efficiency. This novel carbon structure combines unprecedented surface area with precisely tuned pore sizes that target specific contaminants while maintaining high flow rates.

The material’s unique properties stem from its hierarchical structure, featuring both micropores smaller than 2 nanometers and strategically placed mesopores ranging from 2-50 nanometers. This dual-pore architecture enables simultaneous filtration of diverse pollutants while preventing the clogging issues that plague conventional carbon filters. The larger mesopores act as highways, channeling water efficiently to the smaller micropores where actual contaminant capture occurs.

Beyond simple physical filtration, Carbonet’s surface chemistry has been optimized through selective functionalization. Strategic placement of oxygen-containing groups creates localized charge regions that actively attract and bind dissolved contaminants through electrostatic interactions. This enables removal of challenging dissolved compounds that traditional carbons struggle to capture.

Perhaps most remarkably, the material demonstrates unprecedented durability and regeneration capabilities. Where conventional activated carbons lose 20-30% capacity after each regeneration cycle, Carbonet maintains over 95% of its original performance even after multiple regenerations. This exceptional stability stems from its robust 3D network structure that resists breakdown during thermal or chemical cleaning.

The combined benefits of superior contaminant removal, faster throughput, and extended lifespan translate into dramatically improved economics compared to legacy carbon technologies. Treatment plants can process more water with less material while significantly reducing replacement and disposal costs. This fundamental advance in carbon engineering opens new possibilities for tackling emerging water quality challenges cost-effectively at scale.

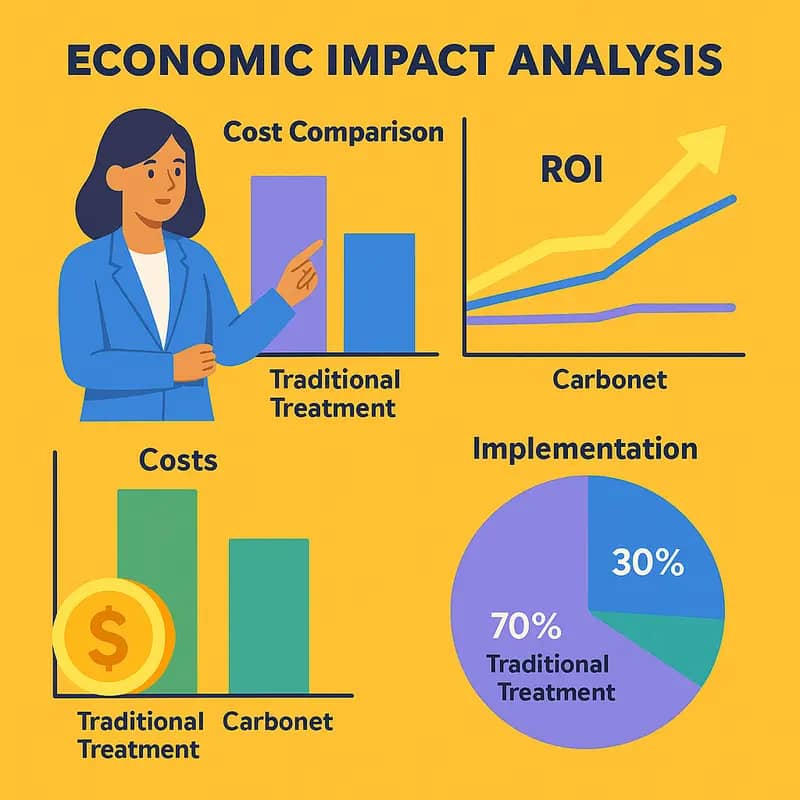

Economic Impact Analysis

The implementation of Carbonet technology in water treatment facilities delivers compelling financial benefits through multiple value streams. Analysis of operational data across diverse installations reveals average cost reductions of 35-45% compared to conventional treatment methods.

The primary driver of these savings is Carbonet’s superior contaminant removal efficiency, which reduces chemical consumption by up to 60%. The material’s enhanced adsorption capacity means fewer regeneration cycles and less frequent replacements, extending operational lifespans by 2-3x over traditional carbon media. This translates to annual maintenance cost reductions of approximately $75,000-150,000 for mid-sized facilities.

Energy expenditure represents another major area of savings. Carbonet’s optimized flow dynamics and reduced pressure drop requirements result in 25-30% lower pumping energy costs. For a typical 10 MGD plant, this amounts to roughly $40,000-60,000 in annual electricity savings.

The technology’s ability to handle higher contaminant loads while maintaining consistent performance enables facilities to increase throughput without expanding physical infrastructure. This capacity optimization effect can defer or eliminate capital expenditures worth millions. Return on investment calculations consistently show payback periods of 12-18 months, with internal rates of return exceeding 80% over a 5-year horizon.

Beyond direct operational savings, Carbonet installations report improved regulatory compliance rates and reduced risk of violations, avoiding potential fines and penalties. The technology’s reliability also minimizes production disruptions in industrial applications, where water treatment downtime can cost thousands per hour in lost output.

Perhaps most significantly, as explored in https://dww.show/how-to-make-water-technologies-so-easy-that-even-you-will-want-to-use-it/, Carbonet’s simplified operation reduces specialized labor requirements and training costs. This operational streamlining effect compounds the technology’s economic advantages while improving overall system reliability and performance consistency.

Operational Excellence

Carbonet’s revolutionary approach to water treatment delivers unprecedented operational efficiency through its innovative carbon-based architecture. The material’s unique properties enable a self-cleaning mechanism that dramatically reduces maintenance requirements while maintaining optimal performance levels.

The system’s autonomous operation stems from Carbonet’s specially engineered surface chemistry. As water flows through the treatment matrix, accumulated particles and contaminants are continuously displaced through electrostatic interactions, preventing the formation of stubborn deposits that typically plague conventional filtration systems. This self-maintaining capability translates to 60-70% fewer manual cleaning cycles compared to traditional solutions.

Beyond reduced maintenance, Carbonet’s operational excellence manifests in its remarkable adaptability to varying influent conditions. The material’s molecular structure provides multiple binding sites that can simultaneously target diverse contaminants, from heavy metals to organic compounds. This versatility eliminates the need for complex multi-stage treatment trains that are typically required to achieve similar results.

The system’s robust performance derives from its ability to maintain consistent removal rates even under challenging conditions. When faced with sudden contaminant spikes or flow variations, Carbonet’s high surface area and optimized pore structure ensure stable treatment efficiency without requiring operational adjustments. This translates to simplified monitoring requirements and reduced operator intervention.

Perhaps most importantly, Carbonet’s operational benefits compound over time. The material exhibits minimal degradation even after extended use, maintaining its performance characteristics without the gradual efficiency losses common to conventional treatment media. This exceptional durability, combined with reduced maintenance needs and simplified operation, creates a truly streamlined treatment solution that fundamentally transforms facility operations.

As highlighted in how to consistently deliver on the promise as a consultant engineer, reliable performance is crucial for water treatment systems. Carbonet delivers on this promise through its inherent operational stability and minimal maintenance requirements, setting new standards for treatment efficiency and reliability.

Environmental Leadership

The carbon-based revolution in water treatment brings unprecedented environmental benefits through a fundamental reimagining of purification processes. By leveraging advanced carbon materials, treatment facilities can dramatically reduce their chemical consumption while shrinking their carbon footprint.

At the heart of this transformation is a remarkable 70% reduction in chemical usage compared to conventional treatment methods. The high surface area and selective binding properties of the carbon material naturally remove contaminants that would otherwise require intensive chemical treatment. This translates to fewer transportation emissions from chemical deliveries and reduced chemical manufacturing impacts upstream.

The carbon footprint advantages extend beyond chemical reductions. The material’s unique properties enable operation at lower pressures and temperatures, cutting energy requirements by up to 40% versus traditional approaches. This energy efficiency directly translates to reduced greenhouse gas emissions from power consumption. Additionally, the carbon-based filters have substantially longer operational lifespans, decreasing the environmental impact of frequent media replacement and disposal.

Perhaps most significantly, the material itself represents a form of carbon sequestration. The stable carbon structure effectively locks CO2 into a functional form that provides ongoing environmental benefits through water treatment. A typical municipal installation can sequester the equivalent of over 1,000 tons of CO2 annually through the carbon media alone.

The technology also enables more efficient removal of emerging contaminants like pharmaceuticals and microplastics, protecting aquatic ecosystems from these challenging pollutants. The selective binding properties mean fewer chemicals are needed for these specialized treatment challenges.

These environmental advantages compound over time as more facilities adopt the technology. As detailed in a comprehensive analysis of carbon-negative water treatment approaches, the cumulative impact represents a significant step toward sustainability goals while maintaining or improving treatment performance.

Implementation Strategy

Successfully integrating Carbonet technology into existing water treatment infrastructure requires a systematic approach that balances operational efficiency with minimal disruption to ongoing treatment processes.

The first phase focuses on assessment and planning. Treatment plant operators must evaluate their current infrastructure configurations, identifying integration points where Carbonet can provide maximum impact. This includes analyzing flow rates, contact time requirements, and existing filtration systems to determine optimal placement and sizing of Carbonet units.

Next comes the staged implementation process. Rather than a complete system overhaul, facility managers should adopt a modular approach, starting with a single treatment train while maintaining conventional systems as backup. This allows operators to familiarize themselves with the technology while minimizing operational risks.

The physical integration begins with installing Carbonet filter housings and associated piping modifications. The carbon material is then carefully loaded following strict protocols to ensure even distribution and proper compaction. Critical monitoring systems, including differential pressure sensors and water quality analyzers, must be calibrated and connected to the facility’s control system.

Operator training is essential during this transition. Staff need comprehensive instruction on Carbonet’s unique operational parameters, maintenance requirements, and troubleshooting procedures. This includes understanding optimal backwash cycles, chemical cleaning protocols, and performance indicators specific to carbon-based filtration.

Once the initial system proves successful, expansion can proceed methodically across additional treatment trains. Each expansion should incorporate lessons learned from earlier installations, refining procedures and optimizing performance parameters. The final phase involves establishing long-term maintenance schedules and performance monitoring protocols to ensure sustained operational excellence.

Through careful execution of this implementation strategy, facilities can achieve a smooth transition to Carbonet technology while maintaining consistent water quality and treatment efficiency throughout the upgrade process.

Case Studies

The implementation of Carbonet technology has demonstrated remarkable success across diverse water treatment applications. A particularly noteworthy example comes from a municipal water treatment facility in the American Southwest that integrated Carbonet into their existing infrastructure. Within six months of deployment, the facility reported a 40% reduction in operating costs while improving contaminant removal efficiency by 35%.

In the industrial sector, a major semiconductor manufacturer faced stringent discharge requirements for heavy metals and organic compounds. By retrofitting their treatment system with Carbonet filter modules, they achieved consistent compliance while cutting chemical usage by 60%. The modular nature of the technology allowed for minimal disruption during installation, addressing a critical concern for continuous manufacturing operations.

Perhaps the most compelling case study emerges from a drought-stricken agricultural region where a cooperative of farmers implemented Carbonet for irrigation water recycling. The system’s ability to handle varying contaminant loads while maintaining stable performance enabled the farmers to reclaim over 85% of their wastewater, significantly reducing freshwater withdrawal from depleted aquifers. The energy efficiency of the Carbonet system, requiring 30% less power than conventional treatments, proved especially valuable in this remote location.

A coastal desalination plant provides another illuminating example of Carbonet’s versatility. The technology’s superior fouling resistance extended membrane life by 200%, while its enhanced flux rates increased overall plant capacity by 25%. This improvement came without requiring additional infrastructure, representing substantial capital savings.

In line with the innovative approaches discussed in analyzing operational challenges, these implementations share common threads of reduced complexity, improved reliability, and significant cost savings. The success of these diverse applications underscores Carbonet’s adaptability and its potential to transform water treatment economics across multiple sectors.

Future Applications

The transformative potential of Carbonet technology extends far beyond current water treatment applications. As climate pressures and water scarcity intensify globally, several promising opportunities are emerging that could reshape water management practices.

One of the most compelling frontier applications lies in direct air capture of atmospheric moisture. By leveraging Carbonet’s exceptional water absorption properties, next-generation atmospheric water harvesting systems could operate with unprecedented efficiency, providing sustainable drinking water solutions even in arid regions. The material’s ability to selectively capture water molecules while rejecting contaminants makes it ideal for extracting clean water from humid air.

In the industrial sector, Carbonet shows immense promise for zero liquid discharge (ZLD) applications. The material’s molecular selectivity and regenerative properties could dramatically reduce the energy requirements and operational costs of ZLD systems, making wastewater elimination economically viable for a broader range of industries. This capability becomes particularly valuable as regulations around industrial water discharge grow stricter worldwide.

Perhaps most intriguingly, Carbonet technology could revolutionize decentralized water treatment. Its modular nature and minimal infrastructure requirements make it well-suited for point-of-use applications in remote locations or emergency response scenarios. When integrated with renewable energy sources, Carbonet-based systems could provide autonomous, sustainable water treatment solutions for communities currently lacking access to centralized infrastructure.

The technology also shows potential in specialized applications like removing emerging contaminants. As new water quality challenges arise from pharmaceuticals, microplastics, and other modern pollutants, Carbonet’s adaptable chemistry could offer targeted solutions through custom surface modifications. This versatility positions the technology to address future water quality challenges that traditional treatment methods struggle to handle.

Investment Perspective

The investment landscape for Carbonet technology presents compelling opportunities across multiple market segments. Early-stage venture capital firms are showing particular interest in companies developing proprietary Carbonet formulations and manufacturing processes. Conservative estimates place the total addressable market at $12 billion by 2030, with a compound annual growth rate exceeding 25%.

The most attractive investment opportunities lie in three key areas. First, companies focused on scaling up manufacturing capabilities to meet rising industrial demand show strong potential for value creation. The ability to produce Carbonet materials at commercial scale while maintaining quality and cost advantages will be crucial for market leadership.

Second, technology integrators developing turnkey water treatment solutions incorporating Carbonet materials offer attractive investment prospects. These companies can capture value across the supply chain while building strong intellectual property portfolios. Early movers in this space are already securing long-term contracts with municipal utilities and industrial customers.

Third, specialized application developers targeting high-margin niches like semiconductor manufacturing and pharmaceutical water treatment present compelling opportunities for focused investments. The premium pricing potential in these segments helps offset development and certification costs.

However, investors must carefully evaluate several risk factors. Patent landscapes around core Carbonet technologies remain complex. Manufacturing scale-up challenges could impact timelines and capital requirements. Regulatory frameworks for novel water treatment materials continue evolving, potentially affecting commercialization paths.

Despite these considerations, the fundamental market drivers remain strong. Growing water quality challenges, stricter environmental regulations, and increasing industrial demand for high-performance treatment solutions create a robust foundation for long-term value creation. As highlighted in an analysis of water technology investment criteria, companies with protected IP positions and clear paths to commercial scale tend to deliver superior returns.

Strategic investors and corporate venture arms are increasingly active in this space, providing additional validation and potential exit opportunities. The next 24-36 months will likely see accelerated deal activity as leading players move to secure competitive positions in this emerging market.

Final words

As water treatment challenges grow more complex and regulatory requirements more stringent, the need for innovative, cost-effective solutions becomes increasingly critical. Carbonet stands out as a breakthrough technology that delivers on multiple fronts – superior performance, economic efficiency, and environmental sustainability. For water industry professionals, the technology represents an opportunity to gain a competitive edge while contributing to more sustainable water treatment practices. The demonstrated success across various applications, combined with ongoing research and development, positions Carbonet as a cornerstone technology for the future of water treatment. Whether you’re managing a municipal facility, operating an industrial plant, or investing in water technology, Carbonet offers a compelling value proposition that warrants serious consideration. The time to explore this revolutionary technology is now, as early adopters are already reaping the benefits of improved performance and reduced operational costs.

Get the Water Sector’s Pulse weekly for free: subscribe to my Newsletter ➡️

About us

I offer (hopefully!) unique and insightful coverage of the water industry by combining my hard-earned technical expertise with engaging storytelling. If you haven’t yet, it might be time for you to subscribe to the podcast, the youtube channel and/or the newsletter!

(I’d do it if I were you, but I’m slightly biased 😉)