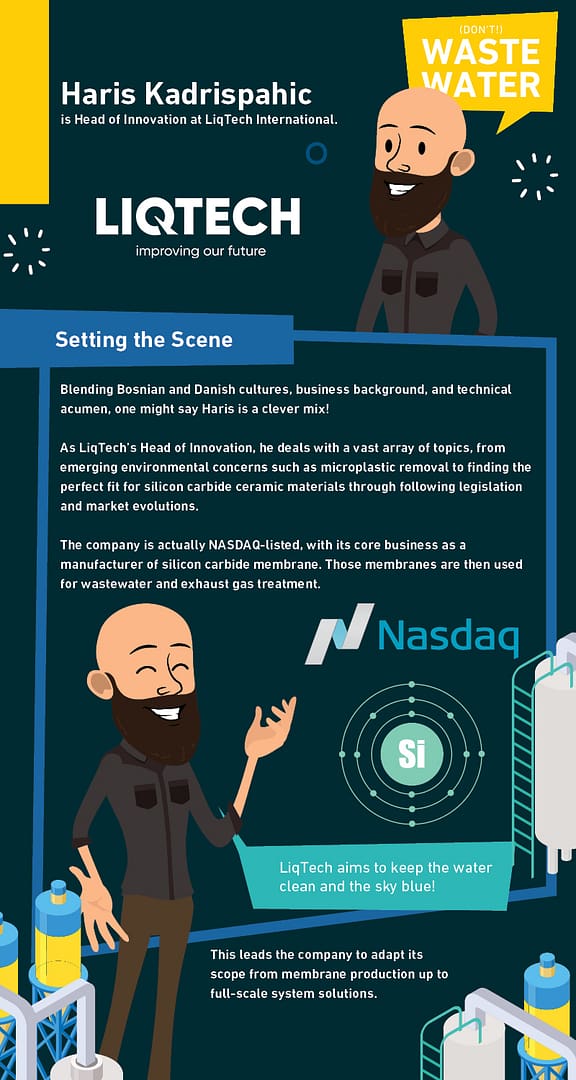

with 🎙️ Haris Kadrispahic – Head of Innovation @ LiqTech International

💧 LiqTech is a technology company specialized in high-end membrane solutions

What we covered:

🍏 How does a Danish Company aiming to develop and produce water and air filtration technologies end-up being NASDAQ listed?

🍏 What makes Silicon Carbide a very special material, when it comes to membrane technologies?

🍏 3 Reasons to prefer ceramic over polymer membranes

🍏 How LiqTech identified the need for a new membrane-type by exploring a new market vertical and how this translates into a brand new hybrid technology

🍏 What might be the future of membrane treatments?

🔥 … and of course, we concluded with the 𝙧𝙖𝙥𝙞𝙙 𝙛𝙞𝙧𝙚 𝙦𝙪𝙚𝙨𝙩𝙞𝙤𝙣𝙨 🔥

➡️ Get the 4 Page Synthesis for free!

Teaser:

Resources:

➡️ Send your warm regards to Haris on LinkedIn

➡️ Visit LiqTech’s website

is on Linkedin ➡️

Full Transcript:

These are computer generated, so expect some typos 🙂

Antoine Walter:

Hi, Harris, welcome to the show. Hello. I’m glad to have you here. Actually, you know, I really enjoyed to start for the postcards and I think it’s the first time that that can start with the postcard from Denmark. So what can you tell me about Copenhagen? Copenhagen

Haris Kadrispahic:

Is a fantastic city. We have a fantastic people, fantastic nature. And for the last 10 years or so, we have also one of the world’s best cuisines, some of the world’s most famous restaurants or the ones at least that we know the prices are here, Noma to be one of them. It’s bit probably unexpected the spore for this Danish capital to be Mecca of the restaurants and food. But that’s the reality.

Antoine Walter:

So you wanted to start by testing how French I am. So to see if I’m going to debate with you about what is the best food and what, okay. I’d take that as a postcard.

Haris Kadrispahic:

I only tend to look at the prices prices and the prices of course, and these restaurants don’t worry. I’m not going to any of them.

Antoine Walter:

Good. let’s start with you actually, can you tell us a bit about your backgrounds and then we will have a look at what you’re doing right now, but I want to know where you’re coming from.

Haris Kadrispahic:

Well I have a very colorful background. I am I’m originally from Bosnia and I moved to Denmark at the age of 13 and had the chance to actually learn about this culture from scratch. And I tend to say that I still keep a lot of my Bosnian culture, but then I modified it through years to be a completely Dane with the, with some more flavor to this Danish lifestyle in professional life. I am a graduate from Copenhagen business school. So not a, a typical technical person you’ll ever meet. Even though I started in technical field, I ended up with a commercial background. So I’m trying to combine lots of different flavors to my day to day work.

Antoine Walter:

That’s an interesting one. You know, our industry is full of engineers, which don’t do engineering and try to do some business. And new are quite the opposite. You have a business background and you’re doing quite technical stuff. How did that happen?

Haris Kadrispahic:

They wanted to work for the government. I always wanted to work for some sort of government agency. I started my early days working for the government. And then after my school finished, I found this work and environmental agency. And through the environmental agency, I met a couple of people who were working in the area of what the treatment and was invited to an interview. I remember now several years later that my boss told me, you know, what, the, this ceramic stuff that you are doing really quite far from that. And he said, well, don’t you worry about ceramics. We’ll teach you everything about ceramics, but we need you to do is to keep everything floating, to keep everything organized and to keep innovating. So, yeah, that’s how I started, but you know what? It went a couple of years later, I was involved in pretty much everything. So, so today I’m glad with the, how things developed. So I’m not I’m, I’m really trying to play my strengths here.

Antoine Walter:

So you mentioned the ceramics, you mentioned the innovation. I think that leads us to your actual role. So you’re head of innovation at leak tech. So what is lik tech actually, and a bit further to that? What is lik tech? I saw that lik tech is listed in the NASDAQ. So you are a business guy doing technical stuff in a company in the Waterworld, which is listed in the NASDAQ. Sounds like, you know, a unicorn, but very special unicorn.

Haris Kadrispahic:

And yeah, I mean, it’s, as I said, it’s kind of a special place to be, and we are a special type of company, I would say. Well, first of all, about LinkedIn, LinkedIn is a manufacturer of Silicon carbide, the membrane for the most part membrane systems and a membrane solutions in general for treatment of wastewater and also exhaust gases. Sometimes people are forgetting that we are also working with diesel particulate filters. It’s wonderful. One of our businesses, basically in our interval, in our company that says this is in order to keep water clean and sky blue. So I couldn’t I couldn’t make it more poetic, but then the ham, of course, the whole business spectrum of water treatment which is we are of course, providers of Silicon carbide membrane and full-scale solution systems. And we will help our customers make growth sustainable when it comes to, in relation to their profits and the environment.

And that’s most important. I mean, we are helping companies to achieve a green growth, as I said, a good place to be when it comes to NASDAQ. That’s a bit more of a history of the company. We were listed in 2012. The New York stock exchange, that’s where we started. And this became this idea that water sector is going to be next, a big growth industry. Maybe some people saw it as a next.com, boom, some some sort of a place where it’s going to be growing, growing. It was, but probably not as much as a lot of people expected, but it still gives us a very sustainable growth. And last year we moved to NASDAQ. And the reason for that is that NASDAQ low comes more of a technological profile of companies. And that’s very found out that it’s more fit for a company such as ours. So if somebody wants to invest in green and not say to Bacco, not to say bad word about tobacco companies, this could be a place and I’m not selling anything here.

Antoine Walter:

So that’s about the company, but what about your, your role you’re head of innovation? So what does that cover?

Haris Kadrispahic:

Well, that covers well, first of all, I started working with development projects, the development projects, this was in early days of lick tech, lik tech internationalist several years ago, we were actually trying to find this perfect fit for our membrane. Not only membrane actually perfect fit for a ceramic material, a Silicon carbide ceramic material. And we had the quite a few different European funded projects, national funded projects in general projects where the several different companies, something is even competitors were involved. That was the original idea for me. And then as time went on I started looking at different markets for our membrane, different innovative fields. Today. We are working in topics such as microplastic removal, just to name something. And also we are heading towards some other potential candidates, such as a chemical industry industry for gas shift where membranes are used, but it’s not on our current portfolio. Other than that from a business perspective I’m also looking at potential markets that could be studying legislation moves from different sectors European union, for example, and trying to, to see where this is heading and how we can fit in into this regulations, because if we face it, if we are real about our industry, it’s it’s very, very dependent on regulation. I mean, no regulation no membrane companies and no exhaust filters.

Antoine Walter:

So, so w what is the latest evolution that you noticed and which is going to trigger something in our industry?

Haris Kadrispahic:

Well, there is a lots of debate here in Denmark. Let’s say let’s start with, because it’s easiest to start home for many years in Denmark it was taught everyone from kids to school, to, to the elderly that water is not treated in Denmark. There is no water treatment because it’s so old, pure ultra clean from nature. We are using for the most part, we are using groundwater, but sometimes you cannot hide away from the fact that, that we need to eat something. And while these farmers are trying to grow potatoes are trying to do, they’re using all types of pesticides in order to, well, to have have their business intact. These are the realities of the world. Now, of course nature will remember now these pesticides that are used 20 years ago will eventually end up in our groundwater and then this groundwater needs to be treated. So this is of course a there’s something that started like academic idea a couple of years ago till today that we are looking at the numbers from, from different waterworks and finding out that well, the levels are quite high. And the, some of the water that we are actually going to intake in next couple of years, needs to be treated. It needs to be treated with our membranes and plus some other technologies, most likely, unfortunately.

Antoine Walter:

So that means that today, if you’re making drinking water treatment in Denmark, you could be removing those trace pesticides, which are in, in the groundwater using your technology

Haris Kadrispahic:

Simple, but in essence, it is, yeah. It is like that. It’s still treatment of this water is people are trying to use some low cost technologies does to keep the treatment that minimum, but this, the treatment of the, of the groundwater will eventually come because at some point this is simple technologies wouldn’t be enough for this type of treatment. So that’s basically what we are looking at right now. And the innovation, when it comes to innovation and that field, we are looking to actually make our membrane active with the active catalyst layer, which would be able to specifically target this compounds. And this is the next step in a, in a membrane evolution. This is very lots of companies. Okay.

Antoine Walter:

So actually, let me guess that must be your new hybrid technology membrane that you’re introducing right now. Actually,

Haris Kadrispahic:

No, we are on our way there, but this is our step to the direction active layer membranes are still on the, on the drawing board. And it, it’s going to be something that we are going to look at in the future, because well, look at your podcast, don’t waste water. I mean, you’ll need to kind of keep lots of compounds that you have in water and these membranes that will eventually come, there’ll be able to actually target the compounds that you want to remove. So if you are working in the food sector, then you could target only let’s say protein and let everything go through. So this would be next step when it comes to hybrid technology membrane it’s step between hybrid technology membrane is first of all, it’s a ultra filtration membrane BR placing it below 100 nanometers, which we are not, they haven’t done so with our commercial Silicon carbide membrane and that membrane, we are looking at customers such as food and beverage industry industry such as there is where we can look at applications that were applications that previously weren’t available for us due to different pore sizes that we had on our membrane.

Antoine Walter:

We’ll come back to this, a new type of membrane, but I’d just like to take just a step back and try to understand what you mentioned earlier as your, the biggest chunk of your business right now, which is your Silicon carbide technology. So for the really stupid, so that’s me, sorry. That means it’s ceramic membrane, right?

Haris Kadrispahic:

It’s ceramic membrane, and it’s not only a ceramic membrane is sometimes there are different types of ceramics. Usually they are made of a carbite which is ours and oxides and oxide. It’s a most common membrane is made of a aluminum oxide. And then after that is a titanium oxide then there is a zirconia membranes, and then there is a carbide membrane such as Silicon carbide. What’s unique about this membranes is that it tends to outperform also the other Silicon carbide membranes. And this is a very relevant in industries where pH values are very, very high. Their viscosity levels are high, and there, there is a problem with the oil level soil water. And in general, the industry is very, you actually need to your membrane to withstand everything you throw at it. And this is where very tend to Excel it. Also, if you look at our business portfolio right now, the markets we in, in oil industry, we are in power plants mining industry. So these are heavy industries, heavy industrial sites. You could say.

Antoine Walter:

So you were at home in harsh conditions if I get it right? Yes. Okay. Do you do the membrane only, or also the module and the systems around

Haris Kadrispahic:

We are right now, two companies. One is where I’m sitting. We are solely producing Silicon carbide membranes, vile lactic water are producing the systems and they are producing turnkey solutions for our customers. Now there is, of course, this, everything between which we share, but usually our customers so far at least would tend to say, you know what? We have this problem, this type of pollution, we need you to solve it for us. And they would come up with the, of course the heart of our system would be Silicon carbide membrane. But then we will, of course, look at the several other technologies for a pre-treatment then after treatment, if necessary, such as our own membranes, various necessary.

Antoine Walter:

Okay. You mentioned when we were discussing about NASDAQ and doctrines, you mentioned that water is, is a growing field. And I think it’s true because the concern, I mean, it’s not the good news somehow. It means that we have always more problems with our water. So we need to treat it always more. But one of the fields, which is the biggest growth over the last probably decade is membrane technology, but correct me if I’m wrong, the biggest chunk of those membranes are the polymer membranes, right? So if I’m very, very sketchy for harsh conditions, you would go to ceramic membranes and eventually to your Silicon carbide technology. And for, let’s say easy waters, you would go for polymer membranes. I mentioned in the beginning emphasis to pay. So I might be totally wrong, but what’s your take there

Haris Kadrispahic:

Completely, right? I mean, this is the history of the membrane, and what’s important to understand that this is not, this is not now me talking like that. Then I’m talking about the whole ceramic industry. What happened in the early days in in membrane world is that the numbers, the sheer volume of produced membranes taken by a polymeric membranes. And this is due to several factors, but the fact is that they are easier to produce one and two. They are cheaper, and this goes kind of hand in hand. So this share volume tends to play a quite significant role for the ceramic companies. Then we needed to play catch up. And we did that for many, many years where we would in order for us to produce membranes, that low price, we need to have a constant order inflow constantly to be able, let’s say to fill our furnaces because furnace is the, is the key when you produce a silicone or any ceramic membrane.

So of course the bigger furnaces you have and the less firing power membrane the price goes down. Now, this tend to go of course hand in hand with the price. So in order for us to keep the price down, we need the order in flow, but we need to fight with the already established market, which is a market for polymeric membrane. Now, for many years, we heard that this is going to switch towards more ceramic area, not only for the industries where polymeric membranes are excluded, but also places such as municipal waste waters, et cetera. And since 2015, 16, we’ve seen some some big projects deliver from some of our competitors, which could look like a good step for the future. And then of course there is a us, or have a, a greater value in, in this heavy polluted or heavy industries.

And of course while we are we have this, all these big projects, it will tend to, to bring price down for ceramic membranes. And then of course, this is like a snowball. All, everything has a snowball effect. Of course, when we bring our prices down, then of course we will be able to offer our customers more value for their money. And then when you have a market acceptance to ceramic membranes, then of course one helps the other. And that just how it goes. The truth is that if, if you look at the market predictions right now, I mean, in the next couple of years, everybody expects that a market will still be dominated by a well, couple of big, big companies. And of course, these big, big companies they have consolidate their positions and they’re using the polymeric membranes. And that’s, that’s just how it is. But then I’m quite optimistic when it comes to ceramic membranes, whether it’s us or a competitor.

Antoine Walter:

So let’s make an exercise. Let’s say I’m operating an industrial wastewater treatment plant, which is a good thing, because in that podcast, you, you cannot imagine how many plants already acquired, but let’s assume I’m operating such a plant. And I have polymer membrane since the nineties. So I’m 30 years in. I cannot say that I have nasty experiences with them, but I’m not so happy neither, but what would be your top three arguments for me to switch from polymers to ceramic? Let’s forget the price because I got your point where with price and the flywheel and the fact that it’s a numbers game, but what would be the top three technical arguments for me to switch?

Haris Kadrispahic:

Well, the best arguments you can have is this, these membranes are indestructible. There is no downtime, essentially. There is no downtime. There is no resting period, which rituals you’ll also see with the, with the polymeric membranes. So basically you can run your operation wherever it is. You can run it. I wouldn’t say nonstop, but almost nonstop. Then there is a, there is of course looking at, and you say that you’ve, let’s not look at the money, but we need to look at the money. I mean, the operations savings are quite high because of this. First of all, downtime is low. Second of all the energy consumption is a much lower than using polymeric membrane. And this is due to a lot of pressure on the, on the system. And then of course I read this article from a, from a British professor is so low of people are just tired of operational problems when it comes to polymeric membranes and they just want to switch to something that, that works. Now, it’s not played simple. You just switch one-to-one and then everything works works. Of course, it’s not, it’s not the, in a perfect world, but using these three arguments, I mean, there is no one who can state that. They have no problem with downtime. They have no problem with high energy consumption. They have no problem with the changing the membranes often et cetera.

Antoine Walter:

So that’s really bad for your long-term business. You set a membrane and then you never have to place them in working for a company which had this problem while assistance were social stable. That’s we just never heard from our customers again. But you know, at some point that’s going to prevent the ultimate groves. Once you’ve populated the full earth with your, your systems. To answer that question,

Haris Kadrispahic:

There is plenty of water out there. It’s not last year. The world spent the $1.5 billion on membranes. This is only last year, and it’s not like this is going away. It’s not like market is everybody’s using membrane. Well, what we can say for sure that there are more and more people needing voter in general, but clean water, also us in Europe, we will, we will experience what the shortage is, is just meadow. It’s just a matter of time. So, so even in Denmark, as I said, we will experience the quality of water will go down. So there is a plenty of opportunities. So that argument that it’s bad for our business, that our customers are happy. It’s not really valid.

Antoine Walter:

So if I just put that in a nutshell, the first argument is no downtime. The second argument is it’s predictable because you can just operate it. You don’t have to have some afterthoughts. And at the end of the day, you have better operating costs because you can run with less pressure. Yes, of course. So that was for silicone, the carbon technology or ceramic membranes, one of which probably the best of which is Silicon carbide technology, but you’re introducing a new type of membrane. So that’s called hybrid technology membrane. So if it’s hybrid, I guess it’s a mix of things. So what exactly is this hybrid technology membrane?

Haris Kadrispahic:

Well, first of all, a bit history again. Okay. I’m sorry. I just need to tell tell stories fascinating. Back in 2015 we were invited to development projects in Denmark, everybody who is anybody within the food sector, food and beverage sector, it was there. So that was your, your vote, just to mention a company that you probably know let’s say it’s probably the best beer in the world. So Carlsberg bird there among amongst others. So slaughterhouses were there.

Antoine Walter:

I just, I have to stop you there because you started the podcast by claiming that the best restaurant in the word I in Copenhagen,

Haris Kadrispahic:

As in Denmark really wants, I’m sorry. They sent probably I’m not arguing against problems, not to argue against that. And the best football club has in Liverpool in the world are using their, on their shirts. Come on. This is, this is winning argument. Okay. No, no, no. Let’s let let’s get no. And so back in 2015, we were invited to this basically it was an amazing project development project. The idea was that food sector, food and beverage sector are going to reduce their use of fresh water intake by 25%. That was in 2015. Now, now after of course nowadays, I mean, everybody, not everybody, but lots, lots of industries are looking at these numbers, like their sustainability goals. So we entered the project with the Silicon carbide membrane envy. So realized that actually our membrane is not suitable for these types of streams.

And yeah, we could use our Silicon carbide membrane as a pre-filtration, but we couldn’t use it for this emerging business which is a protein of concentration, just, just to say, state something. And this was a nice eye-opener. First of all, we had a chance to really talk to companies who could we could all be a round table and they could say, you know what, guys we think you can say, we can save money here in here in here. And they knew everything about their business. And we were voted treatment people. So we know, knew everything about what does, so sometimes it’s just taking a water from one place and placing it another place and then saving some water there. So it was really a nice, a nice exercise, but in the end of the day, we figured out, you know, what, if we are going to be in this market food and beverage industry in general, then we need to do something about our membrane.

So we went back to the drawing board and start looking at different possibilities. Now, Silicon carbide in general is a amazing material, but what’s difficult with Silicon carbide. It’s, it’s not, torturously difficult to control. So if I’m to produce a membrane and say, well, I want a hundred nanometer membrane. I may succeed. But if I say, I’m going to constantly switch between 80 nanometers, 120 nanometers, and back to a hundred nanometers, then I probably wouldn’t be able to do it because it’s very, very difficult to membrane or material to work with. So we figured if you are going to enter industry such as a Fordham beverage, then we need to have several products on the shelf. And one of the criteria, and there are some non-negotiables when it comes to our business. And one is that it needs to be completely chemically inert.

That means that you can throw whatever you want on, on the membrane. It needs to survive. And it needs to have a significant mechanical strength and vivre looking at perfect materials. And we had the, we had some ideas. So we chose the material. There is very, very well-known in the food sector, which is Erchonia oxide. And this is for the grade material, which means that it’s it’s easier to get your product to approve them. So, yeah, so you have an easier, easier way to approve your product by, by using something known as your cornea oxide is a known ceramics, but then again, we needed to keep everything that I said before. So this was basically the project. So create a perfect membrane that we need to have a below. First of all, below a hundred nanometers thesis is what the market expected from us.

And then again, keep our chemical resistance, mechanical resistance impact. So not going to compromise with that. So we made this version of the membrane that is able to check all these points. And what’s great feature about, about this type of membrane is that now we can control it. So if there is a need for a, say a range between a 4,200 nanometers, then we can apply this particular range. So to save, it’s going to be 70 or 80 or 90 or a hundred, which we couldn’t do before with the, with Silicon carbide.

Antoine Walter:

So it opens you the door of the ultrafiltration. If I get you right before you were doing, let’s say microfiltration, and now you can also do a titration or two way oversimplify it. Yes.

Haris Kadrispahic:

That’s a good way to put it. I mean, if you are going to put the ultrafiltration in one bracket, then you can say, yeah, we can, we can do ultra filtration with our Silicon carbide still membrane, but you, you have to, I mean, we are still calling Silicon carbide because majority of the membrane is Silicon carbide.

Antoine Walter:

So that means that basically, you, you keep all the advantages of your material, which by the way, you know, well, and on top of that, you, you add a new capability, which is to be able to control the poor side. And that that’s what helps you to solve the issue in the waste, what to reuse application inside specific segments, such as food and beverage. Exactly.

Haris Kadrispahic:

That was the idea. And that’s, that’s where we succeeded. So, so that’s the next step for us with the, with the hybrid technology is that to make a marketer open eyes for it. And the good way to start is, is is food and beverage industry. So we already have have some, some very nice ideas on and very nice partnerships with, with several end users about this potential technology.

Antoine Walter:

So you’ve released your marketing lounge a couple of weeks ago. What about your, your product roadmap? Where are you right now? Is the product already there? Is it off the shelf? Can it be ordered or do you have some flagship projects you are working on?

Haris Kadrispahic:

She’s going to be next step is more on development of applications then the development of the product. So it’s, it’s going to be our guys in Lichter water are going to make several tests at several different industries and dairy industry being one of them to find the perfect fit for these types of membranes. But then this is only start, of course.

Antoine Walter:

So you mentioned that you have many branches into LinkedIn, and you just said that there’s this, all the leak tech lead tech water, which is going to look at the applications. If I understood right. You, your website, which is beautiful, by the way, there’s also lik tech plastic manufacturing. So you have plastic manufacturer, you have the water systems and you have the membranes, which all together build a full stack company from a to Z. Is that the vision, or do you also work agnostically with other players in the market?

Haris Kadrispahic:

So companies are there because it, they make a lot of sense to what we do. So in general, again, a bit history lipstick, which now Lichter ceramics, which is based in Copenhagen. We existed since 1999, early 2000 it’s 20 years now. So we existed for 20 years and in 2014 we acquired lifter water. So they, they were our customers, basically this engineering companies, vehicle company, which which provided the system. And by doing that of course we entered a whole new field Poland, Spire river. They were really, really amazing. And then several years later now, now we have 20, 20 we did the basically more or less the same thing with the now electric plastic because liquid plastic we’re already component provider to our systems. So we kind of integrated this company into our system. So the basic idea is of course, to have all the knowledge in-house, which of course makes India, it makes the customer happy because we can, we can plan everything to a, from a to Z by ourselves and deliver everything by ourselves.

Antoine Walter:

So that means that in the span of five years, you’ve acquired a LinkedIn quarter, you’ve acquired LinkedIn plastics, which helped you to build the full package solution. You’ve developed the hybrid technology membrane. You found a very good use case at Carlsberg. So, you know, I have, apart from my hobby of acquiring plants in every interview, I have a, another hobby, which is I have my crystal ball and with my crystal ball, I can let you have a look to where lead tech will be in five years. So what’s your vision? Where are you heading?

Haris Kadrispahic:

Oh, yeah. VR VR heading towards being first of all most dominative ceramic membrane provider there’s, there’s no doubt about that. But then we are, we are aiming at in developing new markets and we are also aiming and developing a new solutions to our customers, which are not necessarily only solely based on membranes, but to be able for our customers to chose a full portfolio of different technologies in the water sectors. I think still within five years, we are focusing in, in areas various industrial wastewater. This is most natural fit, but again, I think we, in five years, we’ll have a whole portfolio of different solutions for our customers. Can I ask a very stupid

Antoine Walter:

Question? Let’s say I’m not really oversimplifying, but you had the microfiltration now you have the ultra filtration. What’s next, nanofiltration reverses Moses as it something which is achievable with a ceramic material.

Haris Kadrispahic:

I just have a reverse osmosis. It’s it’s probably a bit stretch. Actually. I was asked by, by this amazing engineer, I had a meeting with the yesterday. He said, why not? Well, there are some limitations and some professors in the, in, in Holland now, not now laugh if they ever heard that, heard this because we had these ideas on the, on the table for, for several years. Next step is definitely going to be nanofiltration within ceramic membranes. It’s, it’s already in the, in the market, but then we’ll have, again, our own flavor and our own take on this types of membranes. That that’s the very, where we are heading. And then don’t forget the, from the start of the interview, I said the, we are probably also going to have some sort of active layer on, on our membrane where we can target a specific components that are, that are unhealthy.

Antoine Walter:

So that would be really aiming. Cause you mentioned the microplastics, but the microplastics are physical pollution, which means can be sorted out with, with membrane pretty logically. But you mentioned also pesticides in there. Think you need to have a kind of active something, which is also targeting those coupons. So that’s the next frontier with selective membrane. If I get you right, is that science fiction or is it something which is really coming in the next decade?

Haris Kadrispahic:

Definitely not science fiction science fiction would be ceramic reverse osmosis membrane and not, not because it’s a, it’s not doable because I honestly think that the reverse osmosis membranes are good as they are. So we would offer pre-treatment solutions that will prolong the life and make life easier for these operators. So there is probably not really need, I don’t see a need out there, but a active layer on a membrane. This is definitely not Saifai. And we already have a couple of projects we are looking at, and we are working on the development with the through a Eurostar program, a European with European union. So, so this is something that we already can see developing. So it’s not, it’s definitely not scifi.

Antoine Walter:

So when, when shall we schedule our next interview to discuss those new member and types two years, five years?

Haris Kadrispahic:

Well, time flies say, let’s say in two years we will definitely have a new product on the, on the shelves. And this is going to be much more amazing than what we have on our portfolio right now. It will even be what we have in HDM membrane.

Antoine Walter:

That’s a really, really appealing takes. Okay. I think I have nothing in my calendar for 2022, so, so far. So

Haris Kadrispahic:

Just before Christmas, just before Christmas and then then we’ll talk there. Perfect. And after that, we’ll have a, we’ll have a lunch. I know this amazing restaurant.

Antoine Walter:

Hey I guess if it’s fine with you, I’d like to switch to the rapid fire questions

Rapid fire questions.

Antoine Walter:

So actually for the record for our questions to rule is pretty simple. I try to keep the questions short. So preferably if you can keep the answers short, that’s good as well. You’ll see that the one which is always deviating from the script is me. So don’t worry. I’m not going to close the microphone if you want to explain a bit longer. So first, what is the most exciting project you’ve been working on and why

Haris Kadrispahic:

Exciting project is a project call LBL, which was a project with the among others with was with the Lake tech and Pentair expo. And that this project was very successful in terms of developing a new membrane. Unfortunately it wasn’t successful for LinkedIn, but it gave us an idea on how to work with our with our membrane in order to come to close to this Pantheris flow.

Antoine Walter:

What is your favorite part of your current job?

Haris Kadrispahic:

Working every day with the most amazing scientists,

Antoine Walter:

You mean scientists in house,

Haris Kadrispahic:

Both, both there is absolutely amazing. There are amazing scientists out there, which I have lots of them I have on my speed dial. And I couldn’t imagine this just 10 years ago. He’s, he’s just an amazing feeling.

Antoine Walter:

Okay. So speaking with all the scientists, you will have a very good answer to the next one, which is what is the trends to watch out in the water industry?

Haris Kadrispahic:

Well, I can stay only for, for the membrane industry transfer. The membrane industry is a more sustainable production which means less chemicals and more reuse, which in the end will will fit nicely towards a, a better product and which goes full circle from production to customers and back to the production.

Antoine Walter:

So that was for the membrane industry. But for the water, would you have take a guess.

Haris Kadrispahic:

Yeah, I will take a shot. I think we’ll see a steep incline in a water technology. What different types of water technology throughout the world, we will also see come back to Europe where I think with the next five years, it could potentially be a growth market. The two different legislations that are envisaged will come shortly.

Antoine Walter:

Okay. So what is the thing you care about the most when you’re working on a new project or developing a new product and what is the one you care? The least

Haris Kadrispahic:

The thing I care about most is that’s easy. One is is the environment. That’s the thing I care about the most. It will get me going. Luckily I have from time to time, I want to say that several times a year, because it is from time to time. I’m sitting around the table with legislators from Europe, but also from, from Denmark. And I’m asked what are technological capabilities of different systems. And I’ll provide them the answer, knowing very well that this is also where legislation will come next time around because a legislator will only play if what’s achievable for the world and in a, not, not more out, of course you cannot legislate for something that is not out there. So this, this is one of the feeling that you that in my job, I really feel that I can, I can make a change for the, for the better that’s, that’s the most amazing feeling of my job.

Antoine Walter:

And what is the thing you cared the least? Oh

Haris Kadrispahic:

My God. That’s the least, no, I’m, I’m, I’m, I’m very excited about lots of things. Well, let’s see. Well, I dunno. I dunno. I honestly don’t know. I don’t know. I don’t know. I need to say I, I I’ve wanted to say our local sandwich shop is not, but I care about least, but the guys are ordering from there, but then sometimes they do other great sandwiches. So that’s not even that it answers your question.

Antoine Walter:

Okay. So I’ll come that as a joker. Do you have sources to recommend, to keep up with the water and waste for the market trends?

Haris Kadrispahic:

I do. I have sources. I tend to read the global water Intel. That’s my that’s kind of my Bible digital Bible. I have to say. Then there are plenty of reports from frost and Sullivan that that tend to read them. There are quite a few national small usually digital sites or papers there that you can get lots of information about our industry.

Antoine Walter:

And last question. Would you have someone to recommend that we should definitely invite as soon as possible?

Haris Kadrispahic:

Yeah, I think you could invite some of our local guys from Denmark, I think can I can provide you a couple with a couple of names, but I have I have this amazing company that are making energy out of a saltwater and freshwater. So this is a, this is the step next step in in a global energy solutions which I’m quite amazed about.

Antoine Walter:

Okay, you’re going to be hooked. So I’m looking for your recommendation. So I guess it was a very interesting interview on my end. I discovered many things, which I totally ignored about Silicon carbide technology and now even hybrids technology membranes. So thanks a lot for that. If people want to follow up with you, where can they find you?

Haris Kadrispahic:

I’m very active on LinkedIn. And I think I’m out now LinkedIn guy. And so if, if somebody wants to, wants to look for leak tech that’s like U T C H for LinkedIn, please follow our page. And you’ll find lots of interesting stuff.

Antoine Walter:

Well, I’ll put the links in the, in the episode notes as well. And that’s a nice way to conclude our session. Thanks a lot. Harris. We have an appointment for 2022. You have to take me to a very nice restaurant heard, so I’m not forgetting that one.

Haris Kadrispahic:

All right. Thank you very much. Cheers.

4 thoughts on “Behind the Scenes of the Hardest Human-Made Material”