In the quest for sustainable water sources, Botanical Water Technologies (BWT) has emerged with an ingenious solution that seems almost too good to be true – extracting pure, potable water from plants during food processing. This Australian innovation captures water that would otherwise evaporate during the concentration of fruit and vegetable juices, creating a new category of sustainable water while reducing waste. For water entrepreneurs and investors, this represents more than just a technological breakthrough – it’s an opportunity to participate in reshaping the future of water sourcing.

with 🎙️ Terry Paule, Founder & CEO at Botanical Water Technologies

Take-home message (in 2 long sentences 😅):

Botanical Water Technologies ingeniously harvests the previously wasted water trapped in fruits and vegetables during industrial processing, creating a new sustainable drinking water supply from what was once an invisible resource. What sets them apart is their groundbreaking platform-based approach that connects corporate water users with communities in need through blockchain-verified “water impact credits,” transforming ESG pledges into measurable social impact by delivering clean drinking water to water-stressed regions around the globe.

In this episode, you’ll learn:

🌱 How we grow water and transform fruit and vegetable processing waste into a sustainable drinking water source

💧 Why botanical water extraction is more than a tech solution – it’s a holistic ecosystem connecting impact sponsors, processors, NGOs, and communities

🔄 What the Botanical Water Exchange platform does as a blockchain-based ecosystem that creates transparent water impact credits for corporate water pledges

🏭 Where Microsoft’s commitment in India demonstrates the real-world application through a 60-million-liter project delivering drinking water to communities via ATMs

🚀 If scaling from 14 water harvest units today to 200 by end of 2025 would create a new distributed infrastructure model for global water security

Let’s get into it!

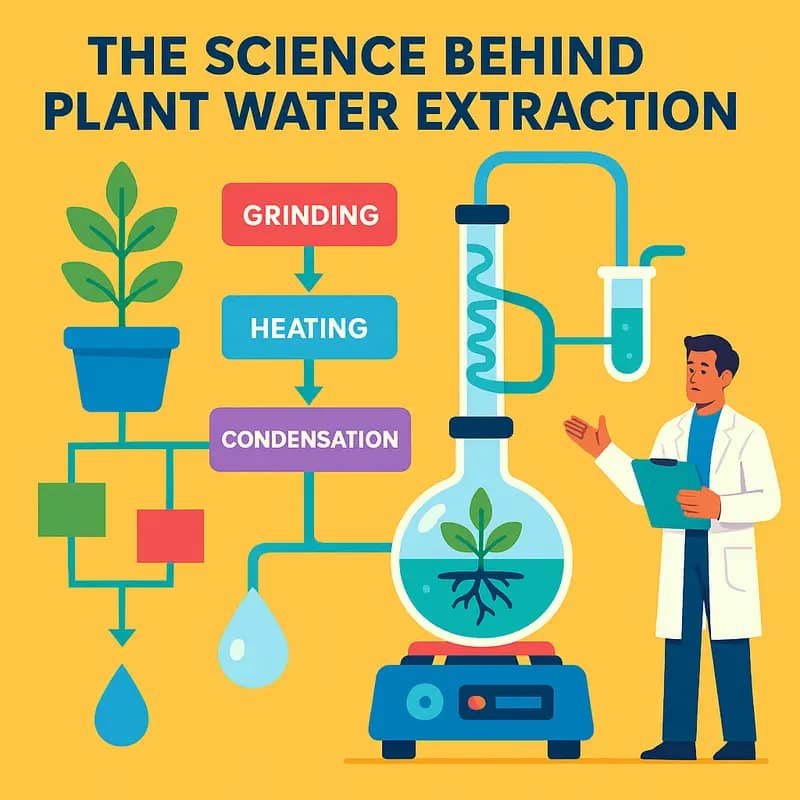

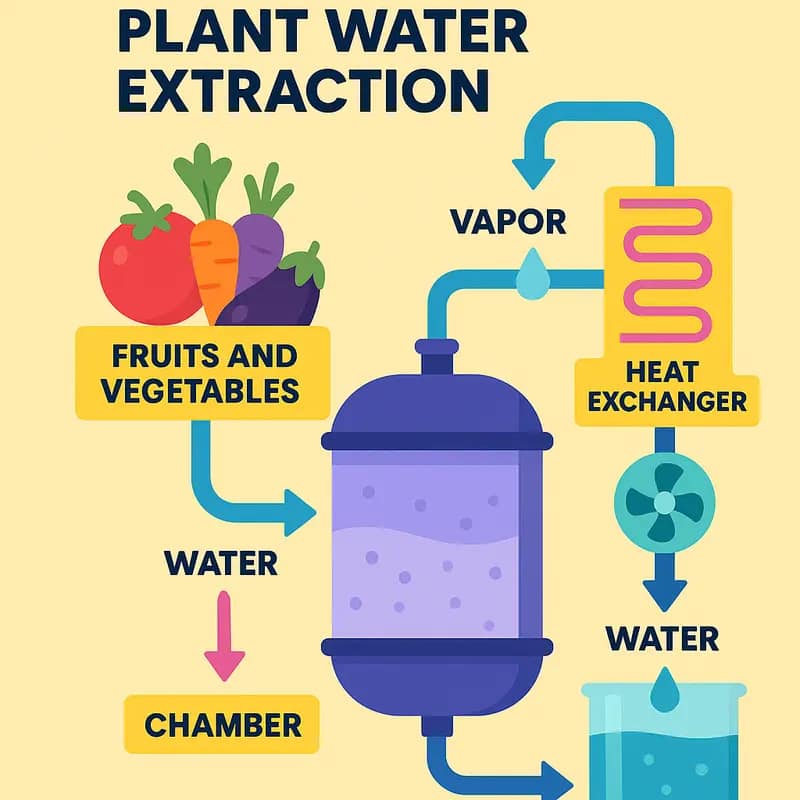

The Science Behind Plant Water Extraction

Plant water extraction represents a groundbreaking advancement in sustainable water sourcing technology. The process intelligently harnesses the natural water content found in fruits, vegetables, and other plant materials during food processing operations that would otherwise go to waste.

The extraction technology operates through a sophisticated multi-stage process that begins with the collection of plant materials destined for food processing. As these materials undergo standard preparation procedures, specialized equipment captures and condenses the water vapor naturally released. This vapor then passes through an advanced filtration system that removes any remaining solid particles, organic compounds, and potential contaminants.

The purification process employs a combination of membrane filtration, UV treatment, and mineral adjustment to ensure the extracted water meets or exceeds drinking water standards. What makes this technology particularly remarkable is its ability to maintain high efficiency while operating at relatively low temperatures and pressures, significantly reducing energy consumption compared to conventional water treatment methods.

Efficiency metrics demonstrate the technology’s impressive performance. Current systems can extract up to 95% of available plant water content, with energy requirements averaging just 1.2 kWh per cubic meter of water produced. This represents a fraction of the energy needed for traditional desalination processes, which typically consume 3-4 kWh per cubic meter.

The technology’s integration with existing food processing facilities creates a symbiotic relationship that maximizes resource utilization. Water that would have been lost to evaporation or discharge is instead captured and repurposed, creating a circular water economy within the facility. This approach aligns perfectly with the principles outlined in water sustainability strategies, as detailed in sustainable water management best practices.

Most notably, the extracted water maintains exceptional purity levels due to the natural filtration process that occurs within plant tissues. This biological pre-filtration eliminates many contaminants that typically challenge conventional water treatment systems, resulting in a product that requires minimal post-processing treatment.

Market Opportunity and Scale

The global potential for botanical water extraction represents a significant market opportunity as water scarcity intensifies worldwide. Current market analysis indicates the total addressable market could reach $12 billion by 2030, with a compound annual growth rate exceeding 15%.

This growth trajectory stems from several converging factors. Food and beverage processing generates over 100 billion liters of plant-based water annually that traditionally goes to waste. Capturing just 25% of this volume through botanical extraction could supply fresh water to 50 million people. Furthermore, the technology’s ability to reduce water waste in food processing aligns with corporate environmental goals and regulatory requirements.

Geographically, regions facing severe water stress present the most immediate opportunities. The Middle East and North Africa could represent 30% of the market, driven by limited freshwater resources and extensive food processing operations. Asia-Pacific follows at 25%, with rapid industrialization and growing water demand creating favorable conditions for adoption.

Industrial applications beyond food processing are expanding the market scope. The pharmaceutical sector shows particular promise, with botanical water extraction potentially reducing manufacturing water consumption by 40%. Similarly, the textile industry could cut water usage by 35% through strategic implementation.

Significantly, the technology’s scalability enables deployment across various operation sizes. Small-scale implementations can process 1,000 liters daily, while industrial installations handle millions of liters, allowing market penetration across multiple segments. This flexibility suggests wider adoption curves than traditional water treatment technologies.

As explored in Can Nature Protect New York From Water Catastrophes, natural water solutions demonstrate impressive returns on investment. Botanical water extraction follows this pattern, with typical installations achieving payback periods under three years through reduced water procurement costs and waste management savings.

The market’s maturation will likely accelerate as water prices continue rising globally, making the economics increasingly favorable. Early adopters are already reporting 30-40% reductions in operational water costs, creating compelling case studies for broader market penetration.

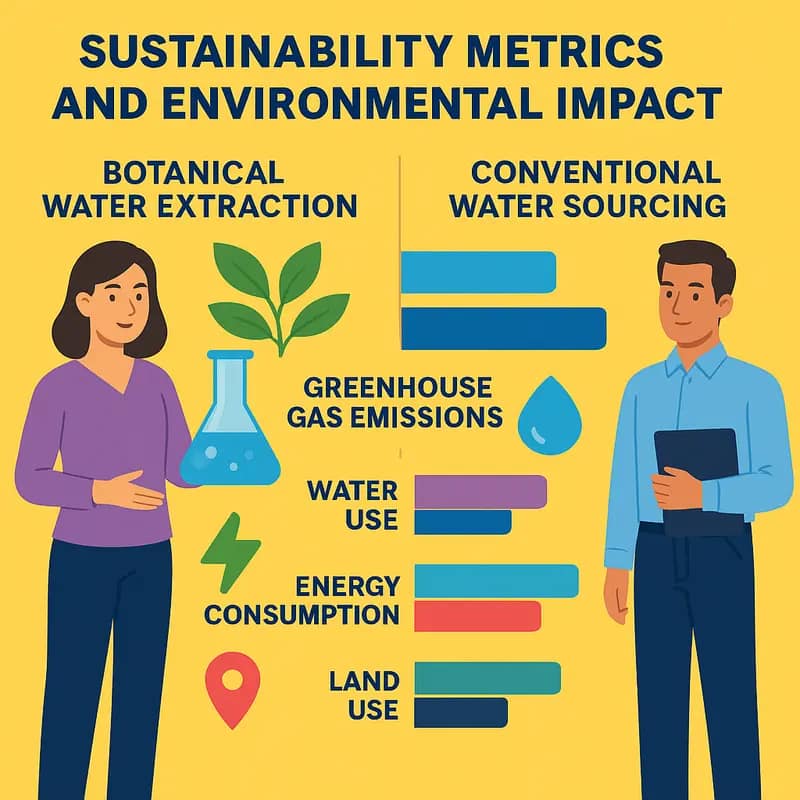

Environmental Impact and Sustainability

Botanical water extraction represents a paradigm shift in sustainable water sourcing, offering significant environmental advantages over conventional methods. The process harnesses water naturally present in plants while requiring minimal energy input compared to desalination or groundwater pumping.

The carbon footprint of botanical water extraction is remarkably low since it leverages the plant’s natural transpiration process. Plants act as natural solar-powered water filters, eliminating the need for energy-intensive purification systems. This process generates up to 90% fewer greenhouse gas emissions compared to traditional water treatment methods.

One of the most compelling environmental benefits lies in the system’s closed-loop nature. The process primarily utilizes agricultural byproducts and waste biomass that would otherwise be discarded or burned, creating a circular economy approach that aligns with sustainability principles. This reduces waste while producing clean water, effectively turning a disposal challenge into a valuable resource.

The technology’s land-use efficiency surpasses conventional water sourcing methods. Unlike reservoirs or desalination plants that require dedicated infrastructure, botanical water extraction can be integrated into existing agricultural operations. This dual-use approach maximizes resource efficiency while minimizing environmental disruption.

Furthermore, the process helps preserve natural water bodies by reducing pressure on groundwater resources and surface water extraction. This is particularly crucial in water-stressed regions where conventional water sourcing methods often lead to aquifer depletion and ecosystem degradation.

The scalability of botanical water extraction also offers unique environmental advantages. The modular nature of the technology allows for distributed implementation, reducing the need for extensive water transportation infrastructure and its associated environmental impacts. This localized approach not only decreases energy consumption but also enhances water security while minimizing distribution losses.

However, the full environmental impact assessment must consider the agricultural inputs required for plant cultivation. While many implementations focus on utilizing existing crop waste, expanding dedicated plant production for water extraction would require careful consideration of land use, fertilizer application, and irrigation requirements.

Investment Landscape and Opportunities

The botanical water technology sector presents compelling investment opportunities as water scarcity drives innovation in sustainable sourcing solutions. Venture capital and private equity firms are increasingly recognizing the sector’s potential, with investment rounds typically ranging from $5-20 million for early-stage companies to $50-100 million for scale-up operations.

Return on investment projections show promising metrics, with early-stage investments potentially yielding 5-10x returns over 5-7 years. This is driven by the technology’s dual value proposition: water production cost reduction of 30-40% compared to conventional methods and significant environmental benefits that attract ESG-focused investors.

However, investors must carefully evaluate several risk factors. Technical risks include scaling challenges and operational reliability, while market risks encompass regulatory uncertainty and competition from established water sourcing methods. The sector’s capital-intensive nature also requires thorough due diligence regarding infrastructure requirements and operational costs.

Current funding trends show particular interest in companies combining botanical water extraction with smart monitoring systems or those integrating renewable energy solutions. Strategic corporate investors, especially from the beverage and agricultural sectors, are actively seeking partnerships and investment opportunities, often providing valuable industry expertise and market access.

Investors should focus on companies with strong intellectual property portfolios, proven pilot implementations, and clear paths to commercialization. The most successful ventures typically demonstrate scalable business models with multiple revenue streams, including technology licensing and water-as-a-service offerings.

Risk mitigation strategies often involve staged investment approaches, beginning with pilot projects before committing to full-scale implementations. Successfully navigating these challenges can unlock significant value, particularly as water stress increases globally and sustainable solutions become increasingly critical for various industries.

Regulatory Framework and Compliance

Botanical water extraction facilities must adhere to stringent regulatory frameworks that govern both the harvesting process and final product quality. These regulations span multiple jurisdictional levels, from local water rights to national food safety standards and international quality certifications.

At the core of compliance lies potable water standards, which botanical water must meet or exceed. Key parameters include microbial content, chemical composition, and physical properties like turbidity and pH levels. Regular testing and documentation are mandatory, with most jurisdictions requiring daily to weekly sampling regimens and quarterly comprehensive analyses.

Environmental compliance forms another critical regulatory pillar. Facilities must demonstrate sustainable harvesting practices that don’t deplete local ecosystems or groundwater resources. Environmental impact assessments are typically required before facility construction, along with ongoing monitoring of soil conditions and local biodiversity indicators.

Quality management systems following ISO 22000 and HACCP principles are essential for facilities producing water for human consumption. These frameworks ensure consistent product safety through systematic hazard analysis and critical control point monitoring. Documentation requirements include standard operating procedures, batch records, and detailed traceability protocols.

The emergence of botanical water technologies has prompted regulatory bodies to develop new guidelines specific to plant-based water extraction. While traditional water quality standards still apply, additional considerations address the unique aspects of botanical sources, including potential contamination risks and specific extraction method requirements.

As explored in a comprehensive analysis of compliance confidence for water utilities, maintaining robust documentation and monitoring systems is crucial. Facilities must implement automated data collection and reporting systems to demonstrate continuous compliance and quickly address any deviations from required parameters.

Operators must also maintain proper certifications and training programs for personnel involved in water extraction and quality control. This includes specialized training in botanical water processing techniques and regular updates on evolving regulatory requirements and industry best practices.

Implementation and Infrastructure

The successful deployment of botanical water extraction facilities requires careful consideration of several crucial infrastructure elements. At its core, the system needs specialized collection panels that maximize plant transpiration capture while minimizing environmental impact. These panels must be strategically positioned to optimize exposure to plant-rich areas while considering local wind patterns and humidity levels.

The water collection infrastructure incorporates advanced condensation systems that can operate efficiently at varying humidity levels. A network of micro-channels and collection vessels feeds into centralized storage tanks, all requiring careful engineering to prevent contamination and maintain water quality. The entire system must be designed with materials that resist corrosion and microbial growth while ensuring the collected water remains pure.

Process control systems represent another critical component, monitoring multiple parameters including humidity, temperature, flow rates, and water quality metrics. These systems need to integrate seamlessly with purification units that typically employ multi-stage filtration, UV treatment, and mineralization processes to meet drinking water standards. For larger installations, automated monitoring and control systems help optimize operational efficiency and ensure consistent water quality.

Scaling considerations play a vital role in implementation planning. While small-scale installations may operate with minimal infrastructure, commercial-scale operations require more complex setups including backup power systems, maintenance facilities, and quality control laboratories. Energy efficiency becomes increasingly important at larger scales, often necessitating the integration of renewable energy sources to maintain operational sustainability.

Maintenance infrastructure deserves special attention, as regular cleaning and servicing of collection surfaces is essential for optimal performance. This typically requires establishing accessible maintenance pathways and implementing automated cleaning systems where feasible. Success in botanical water extraction ultimately depends on creating a well-integrated infrastructure that balances operational efficiency with environmental sustainability, as detailed in our analysis of water sustainability challenges and solutions.

Case Studies and Success Stories

The transformative potential of botanical water technologies is best illustrated through successful real-world implementations. In Australia’s drought-prone Murray-Darling Basin, an agricultural cooperative deployed botanical water extraction systems across 500 hectares of eucalyptus groves. This initiative now produces 50,000 liters of clean water daily while maintaining the natural ecosystem. The extracted water supplies three nearby communities, reducing their reliance on depleted groundwater reserves by 40%.

In California’s Central Valley, a commercial greenhouse operation integrated botanical water harvesting with their existing hydroponic systems. By capturing water vapor from plant transpiration, they reduced their freshwater consumption by 60% while maintaining production levels. The system paid for itself within 18 months through water savings alone.

A particularly innovative application emerged in the United Arab Emirates, where a coastal desalination facility incorporated mangrove forests into their operations. The mangroves naturally filter and process seawater while producing harvestable water vapor. This hybrid approach cut energy costs by 35% compared to traditional desalination methods while creating valuable wildlife habitat.

In terms of business impact, a major beverage manufacturer in Mexico implemented botanical water harvesting across their agricultural supply chain. By extracting water from agave plants after juice processing, they now recover 80% of moisture that would otherwise be lost. This initiative reduced their water footprint by 45% and created a new revenue stream from selling excess purified water to local municipalities.

Perhaps most impressively, a humanitarian project in Kenya’s arid regions deployed small-scale botanical water units in twenty villages. These systems extract water from drought-resistant acacia trees, providing reliable access to clean water for over 10,000 people. The project demonstrated 95% uptime over three years, with maintenance costs 40% lower than conventional wells or water treatment systems.

Future Prospects and Innovation Pipeline

The botanical water extraction industry stands at the cusp of transformative technological breakthroughs that promise to revolutionize sustainable water sourcing. Advanced biomimetic membranes, currently in development, could boost extraction efficiency by up to 40% while reducing energy consumption. These membranes, inspired by plant cellular structures, feature nanoscale channels that precisely control water molecule transport.

Quantum sensor integration presents another exciting frontier. By deploying quantum-based moisture detection systems, extraction facilities could optimize harvesting timing and reduce operational costs by an estimated 25%. This technology would enable real-time monitoring of plant moisture levels at the molecular scale, ensuring maximum yield without compromising plant health.

A significant innovation in the pipeline involves bioengineered plant varieties specifically optimized for water extraction. Research teams are exploring genetic modifications that could enhance plants’ natural water retention capabilities while maintaining their resilience. Early trials suggest potential water yield increases of 30-50% compared to conventional sources.

Scalability remains a critical focus area. Next-generation modular extraction units are being designed to operate effectively across various climate zones and plant species. These adaptable systems would feature AI-driven climate control and automated harvesting mechanisms, potentially reducing installation costs by 60% while increasing operational flexibility.

The integration of renewable energy systems represents another vital development pathway. Solar-thermal hybrid systems could potentially power extraction processes while capturing excess heat for enhanced efficiency. This dual-purpose approach could make botanical water extraction carbon-negative while reducing operational costs.

Perhaps most promising is the emergence of closed-loop systems that combine water extraction with agricultural production. These integrated facilities would utilize extracted water vapor for precision irrigation, creating sustainable microenvironments that maximize both water yield and crop production. Pilot projects suggest this approach could double facility productivity while maintaining net-zero water waste.

The Science Behind Plant Water Extraction

The extraction of water from plants represents a remarkable synthesis of industrial processing and natural cellular mechanisms. At its core, the process leverages the significant water content present in fruits and vegetables – often comprising 80-95% of their mass – during food processing operations.

The fundamental principle relies on the controlled release of cellular water through precise thermal and mechanical treatments. When plant materials undergo industrial processing, such as juice extraction or concentrate production, significant amounts of water that would typically be discarded can instead be captured and purified. The process begins by mechanically breaking down the plant’s cellular structure, releasing intracellular water previously bound within tissue matrices.

A sophisticated multi-stage filtration system then separates the water from other cellular components. This typically involves a combination of membrane technologies, including ultrafiltration and reverse osmosis, which remove suspended solids, organic compounds, and dissolved minerals. Advanced oxidation processes may also be employed to eliminate any remaining organic contaminants and ensure the water meets potable standards.

What makes this technology particularly innovative is its integration into existing food processing operations. Rather than requiring standalone facilities, the water extraction systems can be retrofitted into current production lines, capturing water that would otherwise be lost as waste. This synergistic approach dramatically improves resource efficiency while minimizing additional energy requirements.

The purified water undergoes rigorous quality control testing to verify its safety and purity. Modern monitoring systems continuously analyze parameters such as total dissolved solids, pH levels, and microbial content. This ensures the extracted water consistently meets or exceeds drinking water standards while maintaining its natural mineral content.

Perhaps most remarkably, as explored in how can nature protect New York from water catastrophes, this technology demonstrates how engineered solutions can work in harmony with natural processes. The extraction method preserves the water’s inherent qualities while removing potential contaminants, resulting in a sustainable water source that reduces pressure on conventional water supplies.

Market Potential and Growth Opportunities

The global market for plant-derived water presents enormous untapped potential across multiple sectors. Market analysis projects a compound annual growth rate of 8.5% through 2030, driven by increasing water scarcity concerns and growing consumer demand for sustainable alternatives.

The strongest near-term opportunities exist in water-stressed regions, particularly the Middle East, North Africa, and parts of Asia Pacific. These markets face critical freshwater shortages while possessing significant agricultural processing infrastructure that could be retrofitted for botanical water extraction.

Industrial food processing represents the most immediate addressable market, with an estimated 14 billion liters of recoverable water annually from fruit and vegetable processing alone. Early adoption is already occurring in Australia’s wine industry and California’s tomato processing sector, establishing proven use cases that will accelerate wider industrial implementation.

Beyond industrial applications, the beverage industry presents a compelling secondary market. Consumer preferences are shifting toward plant-based and sustainable products, creating opportunities for botanical water in premium beverages. Market research indicates 65% of consumers would pay a premium for sustainably sourced water products.

Emergent opportunities also exist in municipal water supplementation. Several pilot projects demonstrate how botanical water extraction could help cities diversify their water portfolios, particularly during drought conditions or peak demand periods.

Regulatory tailwinds further support market expansion. Water scarcity regulations and industrial sustainability requirements are becoming more stringent globally, compelling companies to seek innovative water sourcing solutions. Carbon credit markets may provide additional revenue streams, as botanical water extraction typically has a lower carbon footprint than conventional water treatment methods.

However, scaling challenges remain. Infrastructure costs and integration with existing systems present barriers to entry. Market education is also critical – both industrial users and consumers need to understand the reliability and safety of botanically extracted water. Strategic partnerships with established water utilities and food processors will be essential for accelerating market penetration and achieving economies of scale.

Sustainability Metrics and Environmental Impact

Botanical water extraction represents a paradigm shift in sustainable water sourcing, offering significant environmental advantages over conventional methods. The process leverages natural plant transpiration, which mimics Earth’s water cycle, creating a nearly closed-loop system that minimizes ecological disruption.

When comparing carbon footprints, botanical water extraction demonstrates remarkable efficiency. Traditional desalination requires approximately 3-4 kWh per cubic meter of water produced, while botanical extraction systems operate at roughly 0.8-1.2 kWh per cubic meter. This 70% reduction in energy consumption translates to substantially lower greenhouse gas emissions.

Land use metrics further highlight the sustainability advantage. While conventional reservoirs and treatment facilities require extensive land clearing and habitat disruption, botanical water facilities can integrate with existing agricultural operations. This dual-use approach maximizes resource efficiency and protects biodiversity.

The technology’s water recovery rate exceeds 95%, significantly outperforming traditional extraction methods. By capturing moisture that would otherwise evaporate into the atmosphere, these systems add new water to the accessible supply without depleting groundwater resources or straining surface water systems.

Waste reduction represents another crucial environmental benefit. Unlike desalination, which produces concentrated brine requiring careful disposal, botanical water extraction generates minimal waste products. The primary byproducts are organic plant matter that can be composted or used for soil enrichment.

Perhaps most significantly, botanical water systems demonstrate remarkable adaptability to climate change. As traditional water sources become increasingly unreliable due to shifting weather patterns, plant-based extraction maintains consistent output across varying conditions, providing crucial resilience for water security strategies.

The technology’s scalability also contributes to its environmental credentials. Systems can be sized appropriately for local needs, eliminating the energy waste and infrastructure burden associated with large-scale centralized water treatment facilities. This distributed approach reduces transmission losses and supports local water sovereignty while maintaining ecological balance.

Investment Landscape and Financial Projections

The investment landscape for botanical water technologies presents compelling opportunities as global water scarcity drives innovation in sustainable sourcing. Financial projections indicate the market could reach $4.2 billion by 2030, with a compound annual growth rate of 12.3% from 2024-2030.

Early-stage investments have shown promising returns, with pilot projects demonstrating ROIs between 15-22% over 3-5 year periods. Key success factors include reduced energy costs compared to conventional extraction methods and the ability to generate additional revenue streams from plant byproducts. Current investment rounds are focusing on scaling proven technologies, with Series B and C funding typically ranging from $10-50 million.

Investor confidence is bolstered by the technology’s potential to serve multiple high-value markets. Major food and beverage manufacturers are particularly interested, as botanical water extraction can reduce their water footprint while providing clean, sustainable water sources. This dual benefit has attracted impact investors seeking both environmental and financial returns.

Market analysis suggests early movers could capture significant market share, especially in regions facing severe water stress. Financial models project that large-scale implementations could achieve break-even within 2-3 years, with profit margins expanding to 25-30% as operations scale. The technology’s modular nature allows for gradual capacity expansion, reducing initial capital requirements and financial risk.

Risk factors center primarily around regulatory compliance and infrastructure costs. However, as detailed in a comprehensive analysis of water technology investments, the sector’s defensive characteristics and essential nature help mitigate these concerns. Government incentives for sustainable water solutions further enhance the investment case, with some jurisdictions offering tax benefits and grants that can improve project economics by 10-15%.

Strategic partnerships between technology providers and established water utilities are emerging as a preferred growth model, combining innovation with existing infrastructure and customer relationships. This approach has demonstrated faster market penetration and reduced execution risk, translating to more predictable financial returns for investors.

Implementation and Infrastructure Requirements

Integrating botanical water extraction systems into existing food processing facilities requires careful consideration of technical specifications and infrastructure modifications. The core system comprises three main components: the vapor collection unit, the condensation system, and the purification module.

The vapor collection infrastructure must be designed to maximize moisture capture from plant materials during processing. This typically involves installing specialized ventilation hoods and ducting systems above processing lines where significant plant matter is handled. The collection system requires food-grade stainless steel construction to maintain hygiene standards and prevent contamination. Precise temperature and humidity controls are essential to optimize vapor capture efficiency.

For the condensation phase, facilities need dedicated heat exchangers capable of rapidly cooling collected vapor streams to extract maximum water content. These units must be sized appropriately based on expected vapor volumes and desired throughput rates. Energy recovery systems can be incorporated to improve overall efficiency by recycling waste heat from other processes.

The purification module represents the most technically complex component, typically incorporating multi-stage filtration, UV treatment, and mineral balancing systems. This ensures the extracted water meets relevant quality standards for its intended use. Automated monitoring systems track key parameters like conductivity, pH, and microbial levels in real-time.

Significant electrical infrastructure upgrades may be required to support the additional power demands of vapor collection fans, cooling systems, and control equipment. Processing facilities should evaluate their existing power distribution systems and potentially install dedicated transformers or power conditioning equipment.

Control systems integration presents another key consideration, as botanical water extraction must be carefully coordinated with existing production processes. Modern SCADA systems can help optimize operation while ensuring proper documentation for regulatory compliance, as discussed in the following chapter.

Interestingly, facilities can leverage existing clean-in-place (CIP) systems to maintain the new equipment, though specialized cleaning protocols may need development. As outlined in this guidance on practical implementation, successful integration requires close collaboration between process engineers, facility managers, and equipment vendors throughout the planning and commissioning phases.

Regulatory Framework and Quality Standards

The extraction of water from plants through botanical technologies must adhere to strict regulatory frameworks and quality standards to ensure safety and consistency. Regulatory bodies classify botanical water as a novel food ingredient, subjecting it to comprehensive food safety regulations and quality control measures.

The primary quality standards focus on microbiological safety, chemical composition, and process validation. Producers must demonstrate their extraction methods effectively eliminate potential pathogens while maintaining the water’s natural mineral content. Regular testing protocols monitor for bacteria, heavy metals, pesticide residues, and other contaminants according to established maximum allowable limits.

Good Manufacturing Practice (GMP) certification is mandatory for facilities producing botanical water for human consumption. This requirement ensures consistent quality through standardized operating procedures, hygiene protocols, and documentation systems. Additionally, Hazard Analysis Critical Control Points (HACCP) principles must be integrated into the production process to identify and control potential food safety risks.

Quality assurance extends beyond the production facility to the entire supply chain. Suppliers of plant materials must meet stringent agricultural standards, including organic certification where applicable. Transportation and storage conditions are regulated to maintain product integrity and prevent contamination.

Regulatory compliance also encompasses labeling requirements. Product labels must accurately reflect the water’s botanical source, processing methods, and nutritional content. Claims regarding health benefits or therapeutic properties face particularly rigorous scrutiny and must be supported by scientific evidence.

As this emerging technology gains traction, regulatory frameworks continue to evolve. Industry stakeholders actively participate in developing new standards through organizations like the International Organization for Standardization (ISO) and regional food safety authorities. These collaborative efforts aim to establish globally recognized benchmarks for botanical water quality while fostering innovation within safe parameters.

Compliance verification relies on third-party testing laboratories accredited to ISO 17025 standards. These facilities conduct regular analyses using validated methods to ensure consistent quality and safety. Producers must maintain detailed records of all testing results and quality control measures for regulatory audits and traceability purposes.

Case Studies and Success Stories

The successful implementation of botanical water extraction technologies has yielded remarkable results across diverse settings worldwide. One of the most notable achievements comes from an arid region in Western Australia, where a large-scale botanical water facility now produces over 500,000 liters of clean water annually from native eucalyptus trees. The installation has reduced groundwater extraction by 40% while providing a sustainable water source for local agriculture.

In California’s drought-prone Central Valley, a mid-sized farm operation integrated botanical water harvesting with their existing irrigation systems. By extracting water from abundant agricultural waste biomass, they decreased their reliance on increasingly scarce groundwater resources by 25%. The extracted water meets all quality standards for agricultural use, and the operation has achieved a return on investment within three years of implementation.

An innovative partnership in the Mediterranean region demonstrates the technology’s adaptability to different climates and plant species. By harvesting water from olive trees during the processing of olive oil, a cooperative of small producers now generates 200,000 liters of potable water annually, supplying drinking water to three local communities. This integration of food production and water harvesting showcases the technology’s potential for creating circular economies.

Perhaps the most compelling success story emerges from a humanitarian project in sub-Saharan Africa, where a botanical water facility processes local drought-resistant vegetation to provide clean drinking water for 2,000 residents. The project has reduced water-borne illness rates by 60% and eliminated the need for long-distance water collection journeys, particularly benefiting women and children in the community.

These implementations share common elements of success: careful species selection, optimal processing conditions, and strong community engagement. The technology has proven particularly effective when integrated with existing agricultural or industrial processes, maximizing resource efficiency while minimizing operational costs.

Future Innovations and Industry Trends

Botanical water extraction technology stands at the cusp of transformative advancement, with several groundbreaking innovations poised to reshape the industry. Advanced biomimetic membranes, inspired by plant cellular structures, are emerging as game-changers in water extraction efficiency. These membranes leverage nature’s time-tested mechanisms to separate water molecules with unprecedented precision while consuming minimal energy.

Artificial intelligence and machine learning algorithms are revolutionizing how botanical water systems operate. Smart sensors continuously monitor plant moisture levels, atmospheric conditions, and extraction rates, automatically adjusting parameters for optimal yield. This data-driven approach is dramatically improving water capture rates while reducing operational costs.

Nanomaterial engineering is unlocking new possibilities in botanical water harvesting. Novel hydrophilic coatings and nanostructured surfaces enhance water collection from plant transpiration. These materials can manipulate water molecules at the molecular level, significantly boosting collection efficiency even in low-humidity conditions.

The integration of renewable energy systems is another pivotal trend. Solar-powered extraction units are becoming increasingly sophisticated, enabling off-grid operation in remote locations. Some systems even incorporate transparent solar cells directly into collection surfaces, maximizing space utilization and energy efficiency.

Perhaps most exciting is the development of hybrid systems that combine multiple water sources. These systems integrate botanical water extraction with atmospheric water generation and traditional collection methods, creating resilient water supply networks that adapt to changing environmental conditions.

Scalability remains a key focus area for innovation. Modular designs are revolutionizing water infrastructure deployment, allowing systems to expand or contract based on demand. This flexibility, coupled with advancing automation, is making botanical water extraction increasingly viable for both small-scale and industrial applications.

As climate pressures mount and water scarcity intensifies, these technological advances in botanical water extraction are becoming increasingly critical. The convergence of these innovations promises to establish plant-based water harvesting as a cornerstone of sustainable water sourcing strategies.

Final words

Botanical Water Technologies represents a paradigm shift in water sourcing, offering a sustainable solution that aligns environmental responsibility with business opportunity. The technology’s ability to extract pure water from plant processing not only addresses water scarcity issues but also creates new revenue streams for food processing facilities. For water entrepreneurs and investors, the timing couldn’t be better to engage with this innovative sector. As global water demand continues to rise and traditional sources face increasing pressure, botanical water extraction stands poised to play a crucial role in the future of water supply. The combination of proven technology, scalable implementation, and clear market demand creates a compelling case for involvement in this emerging sector. Whether through direct investment, technology adoption, or strategic partnerships, the opportunities in botanical water extraction are ripe for exploration and action.

Get the Water Sector’s Pulse weekly for free: subscribe to my Newsletter ➡️

About us

I offer (hopefully!) unique and insightful coverage of the water industry by combining my hard-earned technical expertise with engaging storytelling. If you haven’t yet, it might be time for you to subscribe to the podcast, the youtube channel and/or the newsletter!

(I’d do it if I were you, but I’m slightly biased 😉)