In the quest for sustainable water treatment solutions, one company stands out by harnessing nature’s most efficient filtration system: algae. Gross-Wen Technologies has developed a groundbreaking Revolving Algal Biofilm system that’s not just cleaning wastewater – it’s transforming it into valuable resources. By combining cutting-edge engineering with natural biological processes, they’ve created an efficient, cost-effective solution that’s catching the attention of water industry leaders worldwide. Their story represents a perfect fusion of innovation and sustainability, showing how thinking differently about waste can create remarkable opportunities.

with 🎙️ Martin Gross, CEO & Co-Founder at Gross Wen Technologies

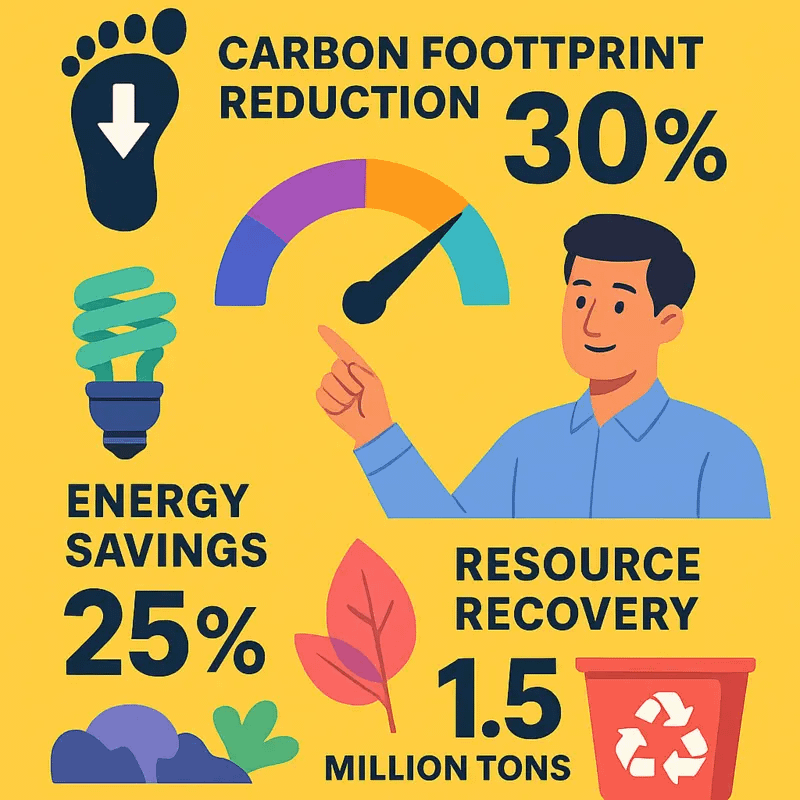

Take-home message (in 2 long sentences 😅): Gross Wen Technologies harnesses the natural power of algae to remove nitrogen and phosphorus from wastewater, creating a sustainable treatment alternative to traditional chemical and bacterial methods. What sets them apart in the water industry is their revolutionary rotating belt system that uses just one-third the energy of conventional nitrogen removal while simultaneously capturing carbon dioxide from the air, offering wastewater facilities a rare triple win of cost savings, nutrient recovery, and climate benefits.

In this episode, you’ll learn:

🌱 How algae-based wastewater treatment provides a sustainable alternative to traditional methods while using a third of the energy for nitrogen removal

💧 Why Gross Wen Technologies pivoted from biofuels to water treatment in 2014, leading to their innovative approach to nutrient recovery from wastewater

🏭 What makes the rotating vertical conveyor belt system uniquely effective for removing nitrogen and phosphorus while simultaneously capturing carbon dioxide

💰 How the company turned algae byproducts into revenue streams through fertilizer production, carbon offset potential, and partnerships with major oil companies

🌐 If the business model evolves from equipment sales to service agreements by 2030, while expanding into both municipal and industrial wastewater markets worldwide

Let’s get into it!

The Birth of a Green Revolution

In the laboratories of Iowa State University, a groundbreaking vision took root when Dr. Martin Gross and Dr. Zhiyou Wen joined forces to tackle one of humanity’s most pressing challenges: water pollution. Their complementary expertise – Gross in environmental engineering and Wen in algal biotechnology – sparked an innovative approach to wastewater treatment that would later revolutionize the industry.

The duo’s eureka moment came from observing nature’s own filtration systems. They recognized that algae, often viewed as a nuisance in water bodies, could become a powerful ally in cleaning contaminated water. Drawing inspiration from natural processes, they began developing what would become the Revolving Algal Biofilm (RAB) system.

Their early experiments faced significant hurdles. Traditional algae cultivation methods required vast spaces and struggled with efficiency. But Gross and Wen persisted, driven by their belief in algae’s remarkable ability to remove nutrients from wastewater while producing valuable biomass. After countless iterations, they achieved a breakthrough by designing a vertical system that maximized algae exposure to both light and contaminated water.

The founding of Gross-Wen Technologies marked the transition from academic research to real-world application. The founders recognized that biologically-inspired solutions could outperform conventional chemical treatments while creating additional value streams. Their algae-based system proved capable of removing nitrogen and phosphorus from wastewater more efficiently than traditional methods, while simultaneously generating biomass for sustainable products.

What began as a research project evolved into a mission to transform wastewater treatment. The founders’ commitment to sustainable solutions attracted early supporters who shared their vision of turning wastewater treatment plants from energy consumers into resource recovery facilities. Their pioneering work laid the foundation for a new era in water treatment, where nature’s own mechanisms could be harnessed to solve modern environmental challenges.

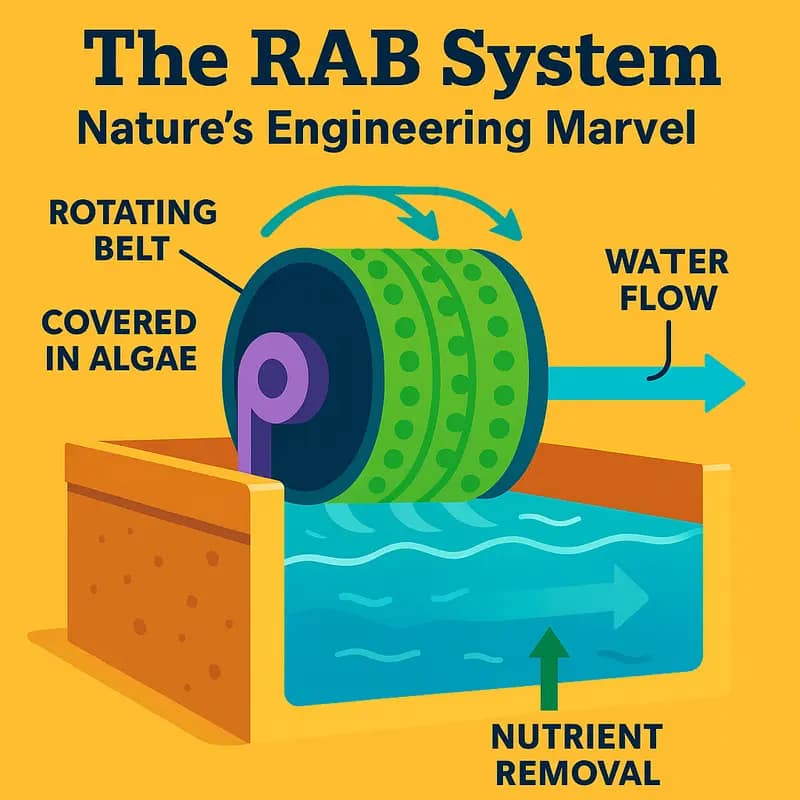

The RAB System: Nature’s Engineering Marvel

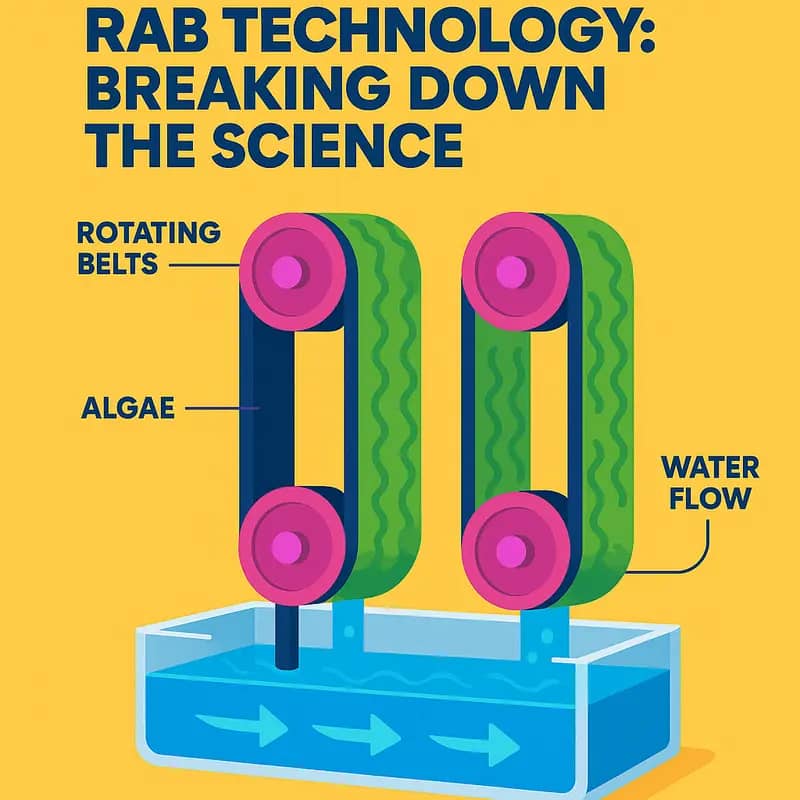

At the heart of Gross-Wen Technologies’ revolutionary approach lies the Revolving Algal Biofilm (RAB) system – an elegant fusion of biological processes and mechanical engineering. Unlike conventional treatment methods, RAB harnesses algae’s natural ability to capture nutrients while maximizing efficiency through an innovative vertical belt design.

The system’s core component consists of vertical belts that slowly rotate through wastewater-filled tanks. As these belts turn, they provide the perfect growth surface for algal biofilms, which naturally absorb nitrogen, phosphorus, and other nutrients from the water. The rotating motion ensures optimal exposure to both light and nutrients while preventing the accumulation of excess biomass.

What truly sets the RAB system apart is its vertical orientation. By growing algae on vertical surfaces rather than in horizontal ponds, the system achieves up to 10 times greater productivity per square foot of land area. The vertical design also shields the algae from contamination and weather fluctuations, ensuring consistent performance year-round.

As the algae-laden belts emerge from the water, they enter a harvesting zone where automated scrapers gently remove the nutrient-rich biomass. This continuous harvesting process maintains optimal biofilm thickness and ensures maximum nutrient removal efficiency. The harvested algal biomass, rich in valuable compounds, becomes a sustainable resource for various applications, from biofertilizers to animal feed supplements.

The RAB system’s closed-loop design minimizes water loss through evaporation, a significant advantage over open pond systems. Additionally, the mechanical simplicity of the rotating belts reduces maintenance requirements and energy consumption compared to traditional treatment technologies.

Perhaps most remarkably, the system achieves superior nutrient removal while producing valuable biomass, effectively turning waste into wealth. This dual benefit fundamentally transforms the economics of wastewater treatment, as facilities can now generate revenue streams from what was previously considered a cost center.

The RAB system represents a perfect example of biomimetic engineering, where nature’s time-tested solutions are enhanced through human innovation. By working with natural processes rather than against them, this technology points the way toward more sustainable water treatment solutions.

Economic Benefits: Where Green Meets Gold

The RAB system’s economic advantages extend far beyond basic wastewater treatment, creating a compelling business case for municipalities and industrial facilities. By harnessing nature’s filtering capabilities through algae, this innovative approach delivers substantial cost savings while generating new revenue streams.

Operational costs see dramatic reductions compared to conventional treatment systems. The RAB’s energy requirements are significantly lower since it eliminates the need for energy-intensive aeration. Its automated rotating mechanism requires minimal power while maximizing nutrient removal efficiency. The system also reduces chemical usage, cutting expenditures on traditional treatment additives.

Maintenance costs remain modest due to the system’s mechanical simplicity and biological resilience. The continuous rotation prevents biofilm accumulation and reduces cleaning requirements. With fewer moving parts than conventional systems, maintenance intervals extend further while repair costs decrease.

The real economic breakthrough comes from the system’s valuable byproducts. The harvested algal biomass serves multiple profitable markets. Rich in proteins and nutrients, it commands premium prices as livestock feed supplements and organic fertilizers. The biomass can also be processed into high-value products like bioplastics and nutraceuticals, opening new revenue opportunities for treatment facilities.

The RAB system’s scalability further enhances its economic appeal. Facilities can start with smaller installations and expand incrementally as needed, allowing for strategic capital deployment. This modular approach helps manage upfront costs while providing flexibility to match treatment capacity with demand growth.

The combination of reduced operational expenses and revenue-generating byproducts creates an attractive return on investment profile. Early adopters report payback periods as short as 3-5 years, with ongoing benefits flowing to their bottom line through reduced treatment costs and biomass sales. This economic performance makes the RAB system particularly appealing for budget-conscious utilities seeking sustainable solutions that strengthen their financial position.

Environmental Impact: Beyond Clean Water

The RAB system’s environmental benefits extend far beyond its primary function of water purification, creating a cascade of positive ecological impacts. At its core, the system harnesses algae’s natural ability to sequester carbon dioxide, operating as a powerful carbon sink that captures greenhouse gases directly from the atmosphere. A single RAB installation can sequester several tons of CO2 annually, rivaling the carbon-capturing capabilities of mature forest stands.

Unlike conventional wastewater treatment systems that demand significant energy inputs, the RAB technology leverages photosynthesis as its primary energy source. This natural process dramatically reduces the energy footprint of water treatment, with facilities reporting up to 90% lower electricity consumption compared to traditional activated sludge systems.

The system’s resource recovery capabilities create a closed-loop sustainability model. The harvested algal biomass serves multiple purposes – from sustainable biofuels to high-value agricultural products. The phosphorus and nitrogen recovered through the process can be transformed into eco-friendly fertilizers, addressing both waste management and agricultural sustainability challenges simultaneously.

Perhaps most remarkably, the RAB system helps preserve natural water bodies by reducing the nutrient load that typically causes harmful algal blooms in receiving waters. By capturing and utilizing these nutrients within the treatment process, the technology prevents the cascade of ecological disruptions that excess nutrients typically trigger in aquatic ecosystems.

The system’s modular design also minimizes land use compared to conventional treatment methods, preserving valuable space while maximizing treatment efficiency. This spatial efficiency, combined with its minimal chemical usage, further reduces the environmental footprint of wastewater treatment infrastructure.

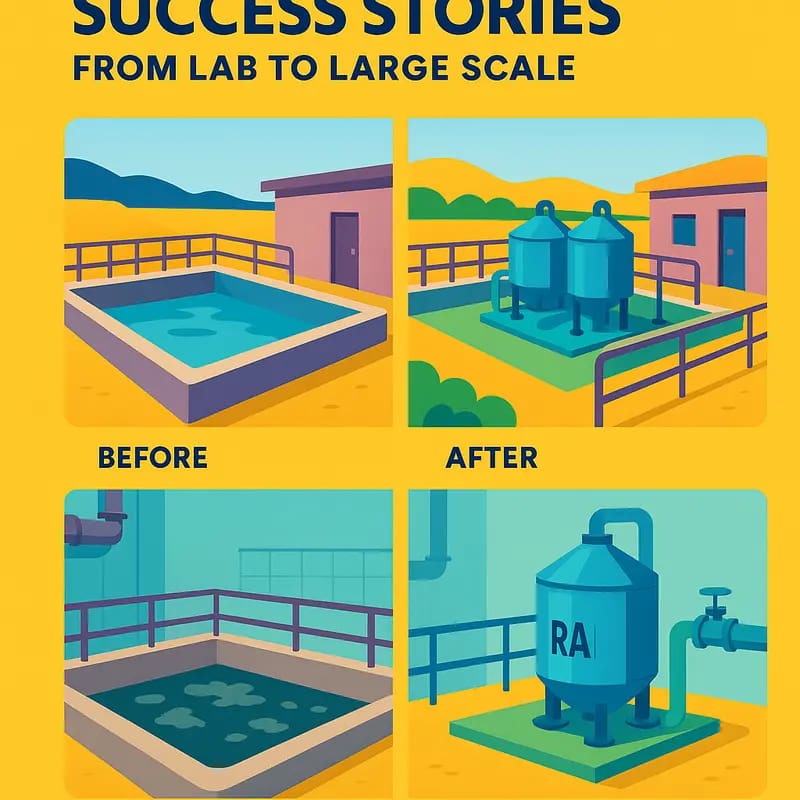

Success Stories: From Lab to Large Scale

The revolutionary journey of Gross-Wen’s RAB system from concept to commercial reality is best illustrated through its groundbreaking implementations across multiple facilities. In Mason City, Iowa, the first full-scale RAB system demonstrated remarkable success in nutrient removal, consistently achieving over 80% phosphorus reduction while generating valuable biomass for agricultural applications.

At the core of these achievements lies the system’s innovative vertical revolving algal biofilm design. The Marshalltown Water Pollution Control Facility provides a compelling example of the technology’s adaptability. Their RAB installation processes 300,000 gallons of wastewater daily while requiring 75% less space than traditional treatment methods. Plant superintendent Bill Jones notes: ‘The system’s ease of operation and minimal maintenance requirements have exceeded our expectations.’

Smaller communities have also reaped significant benefits. The town of Slater, Iowa, facing strict nutrient discharge limits, implemented a RAB system that reduced their compliance costs by 50% compared to conventional alternatives. Town manager Sarah Chen shares: ‘Beyond meeting regulations, we’ve created a new revenue stream through the sale of algal biomass to local farmers.’

Perhaps most impressive is the system’s performance in varying climates. A pilot project in Minnesota demonstrated the RAB technology’s resilience during harsh winters, maintaining consistent treatment efficiency even in sub-zero temperatures. This success opened doors for implementation in regions previously considered challenging for algal-based treatment systems.

These case studies highlight a crucial aspect of the RAB system’s success – its scalability. From treating 10,000 gallons per day in early pilots to managing millions of gallons in current installations, the technology has proven its reliability across different scales and applications. As documented in a recent analysis of green algae solutions, the RAB system’s success lies in transforming a traditional nuisance into a valuable resource while solving critical environmental challenges.

Future Applications: Expanding Horizons

While revolutionizing municipal wastewater treatment remains a core focus, the RAB system’s potential extends far beyond this initial market. The technology’s versatility opens doors to numerous industrial applications where water treatment intersects with resource recovery and sustainability goals.

In the agricultural sector, RAB systems could transform intensive farming operations by treating nutrient-rich runoff while producing valuable biomass for animal feed or soil amendments. The technology’s ability to remove nitrogen and phosphorus while generating usable byproducts presents a compelling circular economy solution for large-scale farms and aquaculture facilities.

The food and beverage industry stands to benefit significantly from RAB implementation. Breweries, dairy processors, and other food manufacturers face increasingly strict discharge regulations while seeking ways to reduce their environmental footprint. The RAB system’s dual capability to treat wastewater and produce renewable resources aligns perfectly with the industry’s sustainability initiatives.

Perhaps most intriguingly, the technology shows promise in the emerging direct air capture (DAC) sector. The algae’s natural carbon sequestration abilities could be leveraged to enhance the efficiency of DAC facilities while simultaneously treating their process water. This application could help make carbon negative fuel, boost utility revenue, and contribute to climate solutions.

The pharmaceutical and cosmetics industries represent another frontier, where high-value compounds extracted from the algal biomass could offset treatment costs. The controlled environment of the RAB system ensures consistent biomass quality, making it suitable for these demanding applications.

As water scarcity intensifies globally, the technology could also play a crucial role in mining operations, helping to treat and recycle process water while recovering valuable minerals. The system’s modular nature and ability to handle varying contaminant loads make it particularly well-suited for these challenging industrial environments.

Investment and Growth Trajectory

Gross-Wen Technologies’ revolutionary RAB system has attracted significant investor attention, positioning the company for accelerated growth in the water treatment sector. Their innovative approach to using algae for wastewater treatment has resonated strongly with both strategic and financial investors seeking sustainable solutions.

The company’s funding journey reflects growing market confidence in their technology. After securing initial seed funding, GWT has successfully closed multiple investment rounds, including a pivotal Series A that brought in experienced water industry investors. This capital injection has enabled rapid scaling of operations and technology deployment across multiple facilities.

Market analysis indicates the global water treatment sector presents a compelling opportunity, with projections showing it reaching $211 billion by 2025. GWT is strategically positioned to capture a meaningful share of this market, particularly in the municipal and industrial segments where sustainable solutions are increasingly mandated.

The company has demonstrated impressive revenue growth, with year-over-year increases exceeding 100% as more facilities adopt their RAB technology. This growth trajectory is supported by expanding market presence and a growing track record of successful installations. How to make water technologies more attractive than the Apple and Samsungs of this world shows why companies like GWT are gaining increased attention from investors.

Operational metrics further validate the investment thesis. Treatment facilities using GWT’s technology report significant cost savings compared to conventional systems, while meeting or exceeding regulatory requirements. This proven performance has helped secure additional contracts and partnerships, creating a robust pipeline for future growth.

Looking ahead, GWT’s investment strategy focuses on three key areas: expanding manufacturing capacity, enhancing technology capabilities, and strengthening market presence. The company’s solid financial foundation and growing market acceptance position it well for continued expansion in the water treatment sector.

Innovation Pipeline: What’s Next for GWT

Gross-Wen Technologies stands at the cusp of several groundbreaking developments that promise to expand the capabilities and applications of their revolutionary algae-based water treatment system. Building on their proven RAB technology, GWT’s R&D pipeline focuses on enhancing nutrient recovery efficiency while exploring new revenue streams from algal biomass.

A key focus area involves optimizing the algal strains used in their systems. Advanced genomic research aims to develop specialized algae varieties that can target specific contaminants while maximizing biomass production. This dual-purpose approach aligns with GWT’s commitment to solving environmental issues while creating valuable byproducts.

The company is also developing smart monitoring systems that leverage artificial intelligence to optimize algae growth conditions in real-time. These systems will automatically adjust parameters like light exposure, nutrient levels, and harvesting cycles to maximize treatment efficiency across varying conditions and seasons.

Perhaps most excitingly, GWT is exploring novel applications of their algal biomass beyond conventional biofuel and fertilizer markets. Ongoing research investigates using processed algae in sustainable packaging materials, specialty chemicals, and even pharmaceutical applications. These diversified end-uses could significantly boost the technology’s economic viability.

System scalability remains another crucial development focus. Engineers are working on modular designs that can be easily expanded or contracted based on treatment needs. This flexibility will make the technology accessible to both small communities and large metropolitan areas.

Through strategic partnerships with research institutions and industry leaders, GWT continues pushing the boundaries of algal biotechnology. Their innovation pipeline reflects a holistic approach to water treatment – one that views waste streams not as problems to solve, but as resources to be transformed through nature’s most efficient filtration system.

The Genesis of Innovation

In the laboratories of Iowa State University, a groundbreaking idea took root that would transform how we approach water treatment. Dr. Martin Gross and Dr. Zhiyou Wen observed a fundamental challenge: conventional wastewater treatment methods were energy-intensive and struggled to remove excess nutrients effectively. Their solution would harness one of nature’s most ancient and efficient filtering mechanisms – algae.

Their research focused on developing a system that could leverage algae’s natural ability to consume nutrients while producing valuable biomass. The breakthrough came when they designed a revolutionary rotating belt system that would maximize algal growth and nutrient removal simultaneously. This innovation would later become the foundation of Gross-Wen Technologies.

The timing couldn’t have been more critical. Municipalities across America were facing increasingly strict regulations on nutrient discharge, while simultaneously seeking more sustainable treatment solutions. The team recognized that their research could address both challenges – treating water more effectively while creating a circular economy approach to resource recovery.

In 2014, Gross-Wen Technologies emerged from the university setting with a clear mission: to commercialize their patented Revolving Algal Biofilm system. The company’s formation represented more than just another startup – it marked the beginning of a paradigm shift in wastewater treatment philosophy.

What set their approach apart was its elegant simplicity. Rather than fighting against natural processes or relying heavily on chemical treatments, they worked with nature’s own mechanisms. The algae not only removed nitrogen and phosphorus more efficiently than conventional systems but also produced valuable byproducts that could be used in agricultural and industrial applications.

As evidenced in how-to-make-wastewater-treatment-plant-remarkably-carbon-negative, this innovative thinking aligns perfectly with the growing push toward carbon-negative treatment solutions. The founding team’s vision went beyond just cleaning water – they saw the potential to transform wastewater treatment facilities from cost centers into resource recovery centers.

RAB Technology: Breaking Down the Science

The Revolving Algal Biofilm (RAB) system represents a paradigm shift in wastewater treatment by harnessing nature’s most efficient filtration mechanism. At its core lies a series of vertically oriented rotating belts partially submerged in wastewater. These belts provide an ideal growth surface for naturally occurring algae, which form a living biofilm as they rotate through both air and water phases.

The mechanical simplicity of the RAB system belies its biological sophistication. As the belts rotate, algae alternate between submersion in nutrient-rich wastewater and exposure to air and sunlight. This creates optimal conditions for photosynthesis and nutrient uptake. During the submerged phase, algae cells actively absorb nitrogen, phosphorus, and other pollutants from the wastewater. In the air phase, they access CO2 and sunlight to drive photosynthesis, converting these nutrients into valuable biomass.

Unlike conventional treatment systems that rely heavily on energy-intensive aeration and chemical additions, the RAB system operates with minimal energy input. The natural metabolic processes of algae do most of the work. The rotating motion ensures even exposure of the biofilm and prevents the formation of dead zones or channeling that can plague static systems.

Perhaps most remarkably, as discussed in how to fight a pandemic with the help of your feces, the RAB technology achieves superior nutrient removal while producing valuable byproducts. The harvested algal biomass contains high concentrations of proteins, lipids, and other compounds with applications in biofuels, fertilizers, and specialty chemicals. This creates a circular economy opportunity where waste treatment generates revenue streams rather than just operating costs.

The RAB design also overcomes key limitations of other algae-based systems. Traditional pond systems require extensive land area and suffer from poor light penetration and mixing. The vertical orientation of RAB maximizes space efficiency while ensuring optimal light distribution throughout the biofilm. The continuous rotation prevents biomass settling and maintains consistent treatment performance.

Economic Impact and Market Potential

The economic proposition of algae-based wastewater treatment extends far beyond operational cost savings. While traditional treatment methods strain municipal budgets through high energy consumption and chemical costs, algal systems create multiple revenue streams while reducing expenses.

The primary cost advantage comes from lower energy requirements, as algae naturally remove nutrients without energy-intensive aeration. Early pilot implementations show operational cost reductions of 40-60% compared to conventional activated sludge systems. These savings compound over time as energy prices continue rising.

But the real economic potential lies in valorizing the algal biomass produced. The harvested algae finds ready markets in agricultural fertilizers, biofuels, and specialty chemicals. Conservative estimates place the value of biomass products at $500-1000 per ton, creating a steady revenue stream that can offset treatment costs or generate profit for utilities.

The carbon capture capabilities unlock another financial opportunity through carbon credit markets. Each ton of algae produced sequesters approximately 1.8 tons of CO2. At current carbon prices averaging $30-50 per ton, a mid-sized treatment plant could generate over $100,000 annually in carbon credits alone. As carbon markets mature and prices rise, this revenue stream will likely grow substantially.

The global market for algae-based wastewater treatment is projected to expand rapidly, driven by stricter environmental regulations and growing water scarcity concerns. Industry analysts forecast the market reaching $3.4 billion by 2025, representing a compelling opportunity for early movers in the space.

Most significantly, the technology helps utilities transition from cost centers to revenue generators – a paradigm shift explored in detail at dww.show/what-if-you-could-save-12000-liters-a-year-from-the-tip-of-your-foot. By creating value from waste streams while reducing operational expenses, algal treatment systems offer a path to financial sustainability for water infrastructure.

Environmental Benefits and Sustainability

The algae-based RAB system represents a paradigm shift in wastewater treatment, delivering multiple environmental benefits that align with urgent sustainability imperatives. At its core, the system harnesses nature’s own filtration mechanisms to create a virtuous cycle of environmental improvement.

Perhaps most significantly, the RAB technology drastically reduces the carbon footprint of wastewater treatment. Traditional treatment processes are notoriously energy-intensive, often ranking among municipalities’ largest power consumers. In contrast, the algal system actively sequesters carbon dioxide as the microscopic plants grow and multiply. Early implementations suggest carbon capture rates of up to 40% higher than conventional treatment methods.

Water quality improvements represent another crucial environmental advantage. The algae naturally remove excess nutrients like nitrogen and phosphorus, preventing these pollutants from reaching natural waterways where they could trigger harmful algal blooms. The system achieves removal rates exceeding 90% for these key contaminants while also reducing heavy metals and other toxins.

The technology’s contribution to circular economy goals is equally impressive. Rather than viewing wastewater treatment as a linear process that generates waste, the RAB system transforms it into a closed loop. The harvested algal biomass becomes a valuable resource – it can be processed into biofuels, agricultural fertilizers, or nutritional supplements. This productive reuse of what was once considered waste exemplifies circular economy principles.

Importantly, the system’s environmental benefits compound over time. As the algae grow, they become increasingly efficient at nutrient removal and carbon sequestration. The technology also reduces reliance on chemical treatments, minimizing the environmental impact of manufacturing and transporting these substances. This natural approach to water purification demonstrates how working with biological processes rather than against them can yield superior environmental outcomes.

The scalability of the RAB system means these environmental advantages can be replicated across different contexts and locations, multiplying the positive impact. From small rural communities to large urban centers, the technology offers a sustainable path forward in wastewater management.

Real-World Applications and Case Studies

The revolutionary RAB system has demonstrated remarkable success across diverse implementations, with documented performance metrics validating its effectiveness in real-world settings. One notable municipal installation in Iowa achieved a 95% phosphorus removal rate while generating valuable biomass for agricultural applications. The facility processes 2 million gallons of wastewater daily, reducing operating costs by 30% compared to conventional treatment methods.

In the industrial sector, a food processing plant implemented the RAB system to address high-nutrient effluent challenges. Within six months of operation, the facility reported an 85% reduction in nitrogen levels and significantly lower chemical usage. The algae biomass byproduct generated additional revenue streams through conversion to biofuels and agricultural supplements.

A particularly compelling case study emerges from a rural community treatment plant struggling with stringent discharge requirements. By integrating the RAB system, they not only met regulatory standards but also reduced energy consumption by 40%. The modular nature of the technology allowed for phased implementation, making it financially feasible for the small municipality.

Quantitative analysis across multiple installations reveals consistent patterns: phosphorus removal rates averaging above 90%, nitrogen reduction exceeding 80%, and biomass production of 5-7 tons per million gallons treated. These results align with laboratory predictions while delivering additional benefits in real-world applications.

Operational data from a year-long study at a midwest treatment facility demonstrated the system’s resilience through seasonal variations. Winter temperatures showed minimal impact on treatment efficiency, while summer months yielded increased biomass production. The adaptive control systems maintained stable performance despite fluctuating input conditions, proving the technology’s reliability for continuous operation.

These implementations have established a strong foundation of empirical evidence supporting the RAB system’s effectiveness across diverse applications. The documented success in both municipal and industrial settings provides valuable insights for future deployments and continues to drive optimization of the technology.

Future Growth and Innovation Pipeline

Building on its proven success with the RAB system, Gross-Wen Technologies is charting an ambitious course for continued innovation and expansion. The company’s development roadmap focuses on three key areas: technological advancement, market expansion, and sustainability impact.

On the technology front, engineers are finalizing an enhanced RAB system that promises to reduce energy consumption by an additional 30% while increasing algae biomass yields. This next-generation platform will incorporate machine learning algorithms to optimize growing conditions and harvesting cycles automatically. Advanced sensors and controls will enable predictive maintenance, reducing downtime and operating costs.

Geographic expansion represents another crucial growth vector. The company plans to extend its presence beyond the American Midwest into water-stressed regions across the Southwest and coastal areas. International markets, particularly in Asia and the Middle East, present significant opportunities where algal treatment aligns with sustainable development goals.

A groundbreaking initiative in the research pipeline involves developing specialized algae strains capable of targeting emerging contaminants, including pharmaceuticals and PFAS compounds. These enhanced biological capabilities could revolutionize how treatment facilities address complex water quality challenges. The company is also exploring novel biomass applications, from sustainable building materials to high-value nutraceuticals.

Partnerships play a vital role in this growth strategy. Collaborations with research institutions are accelerating the development of new algae strains, while relationships with engineering firms facilitate seamless system integration. The company actively participates in water innovation accelerators, fostering connections that could lead to transformative solutions.

Leveraging its experience in municipal and industrial applications, Gross-Wen is developing a compact, modular version of the RAB system for smaller-scale applications. This innovation could open new markets in decentralized treatment, agriculture, and developing regions where conventional infrastructure is impractical.

Through these strategic initiatives, Gross-Wen Technologies is positioning itself to address evolving water treatment challenges while scaling its impact on global water quality and resource recovery.

Investment Landscape and Market Position

Gross-Wen Technologies has carved out a distinctive position in the water treatment market through strategic funding rounds and key partnerships that validate its revolutionary RAB system. The company’s trajectory mirrors broader industry trends toward sustainable water solutions, with investors increasingly recognizing the potential of nature-based treatment approaches.

Strategic investment partners have backed Gross-Wen’s vision with significant capital infusions, recognizing both the environmental and commercial potential of algal biotechnology. The company’s funding rounds have attracted a mix of venture capital firms focused on cleantech, corporate strategic investors from the water sector, and environmentally conscious impact investors seeking triple-bottom-line returns.

In the competitive landscape of water treatment technologies, Gross-Wen has differentiated itself through its unique value proposition of delivering both nutrient removal and biomass valorization. While conventional technologies typically address only treatment, the RAB system’s ability to generate valuable byproducts creates additional revenue streams that enhance the overall economics.

The company has strengthened its market position through partnerships with municipal utilities, which serve as both customers and validation sites. These relationships have helped establish credibility while providing real-world performance data that supports broader commercial adoption. Additionally, collaboration with agricultural and industrial players has opened new market segments beyond municipal wastewater treatment.

As private capital increasingly flows into water innovation, Gross-Wen’s demonstrated ability to deliver both environmental and economic benefits positions it favorably for continued growth. The company’s focus on developing intellectual property around its core technology while building a strong network of implementation partners has created defensive moats that help maintain its competitive advantages.

The broader market dynamics also work in Gross-Wen’s favor, as regulatory pressures and sustainability mandates drive adoption of advanced treatment solutions. With water utilities and industrial facilities facing stricter nutrient discharge limits and increasing pressure to reduce their environmental footprint, the company’s naturebased approach resonates with both operational and strategic priorities.

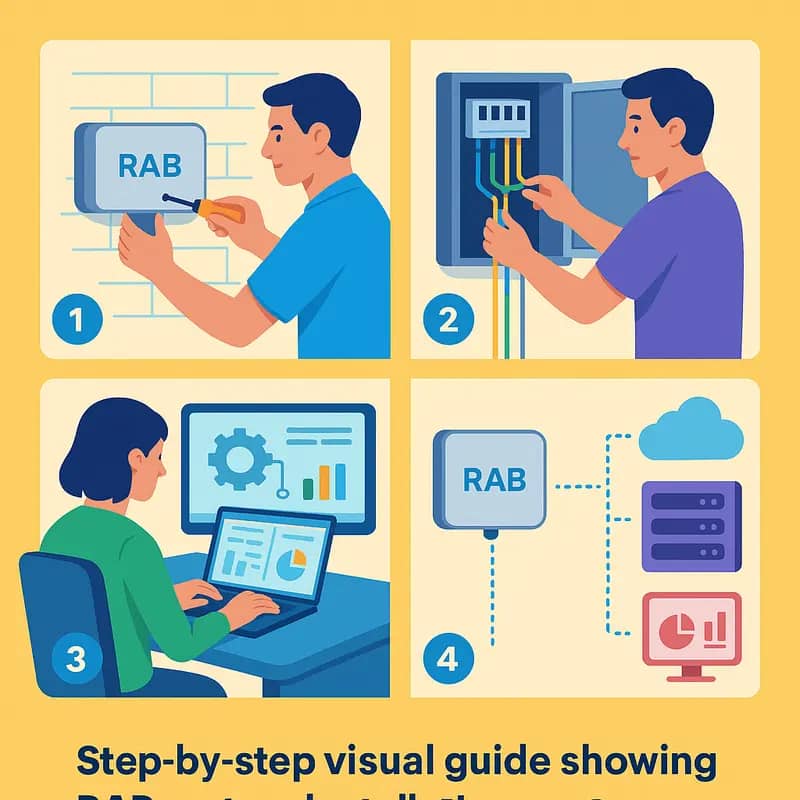

Implementation and Integration Guide

Integrating Revolutionary Algae Biotechnology (RAB) systems into existing water treatment infrastructure requires careful planning and a phased approach. Water utilities and industrial facilities must first evaluate their current operations, infrastructure capacity, and treatment goals before beginning implementation.

The initial assessment should analyze wastewater characteristics, including flow rates, nutrient loads, and space constraints. This data informs system sizing and configuration requirements. Facilities typically start with a pilot program covering 5-10% of their total flow to validate performance and refine operating parameters.

Physical integration begins with site preparation and establishing proper connections to existing treatment trains. The RAB system requires adequate sunlight exposure and temperature control systems to maintain optimal algae growth conditions. Integration with supervisory control and data acquisition (SCADA) systems enables automated monitoring and control of critical parameters like pH, dissolved oxygen, and nutrient levels.

Staff training is essential for successful implementation. Operators need comprehensive instruction on system operation, maintenance procedures, and troubleshooting protocols. Regular assessment of algae health indicators and harvesting timing helps optimize nutrient removal efficiency and biomass production.

Scaling up from pilot to full implementation should follow a gradual approach over 12-18 months. This allows time to optimize configurations, develop standard operating procedures, and ensure stable system performance. Facilities should plan for temporary redundancy during the transition to maintain treatment compliance.

Regulatory compliance and permitting requirements vary by jurisdiction. Early engagement with regulatory agencies helps identify necessary modifications to existing permits. Documentation of water quality improvements and reduced chemical usage supports permit negotiations.

Long-term maintenance planning must account for periodic cleaning of photobioreactors, replacement of filtration components, and management of harvested algal biomass. Establishing relationships with qualified service providers ensures reliable technical support.

Implementation success relies heavily on stakeholder engagement. Regular communication with facility staff, management, and community members builds understanding and support for this innovative approach to wastewater treatment.

Final words

Gross-Wen Technologies stands at the forefront of a paradigm shift in water treatment technology. Their RAB system represents more than just an innovative solution; it’s a blueprint for the future of sustainable water management. By proving that environmental stewardship and economic viability can coexist, they’ve created a model that others in the industry are sure to follow. The company’s success demonstrates that when we work with nature rather than against it, we can solve complex environmental challenges while creating new value streams. As water scarcity and quality issues continue to grow globally, technologies like the RAB system will become increasingly critical. For water industry professionals, investors, and environmental stewards, Gross-Wen Technologies offers not just a product, but a vision of a more sustainable future. Their journey from academic research to commercial success shows that with the right combination of innovation, persistence, and market understanding, transformative solutions are possible.

Get the Water Sector’s Pulse weekly for free: subscribe to my Newsletter ➡️

About us

I offer (hopefully!) unique and insightful coverage of the water industry by combining my hard-earned technical expertise with engaging storytelling. If you haven’t yet, it might be time for you to subscribe to the podcast, the youtube channel and/or the newsletter!

(I’d do it if I were you, but I’m slightly biased 😉)