Lithium exists in many shapes, essentially along its refining value chain. Yet when it comes to integrating it in EV batteries, lithium hydroxide tends to be the most popular one, almost taking over the historical lithium carbonate player. Let’s review in a bit more details:

Table of contents

What are the different Lithiums used in Batteries?

Since the early days of acid-lead batteries Thomas Edison worked on, the storage of electricity has evolved towards greater use of Lithium and Lithium-ion solutions.

There are different variations of Lithium, though, that all play a certain role across the electric battery value chain, let’s swiftly define them.

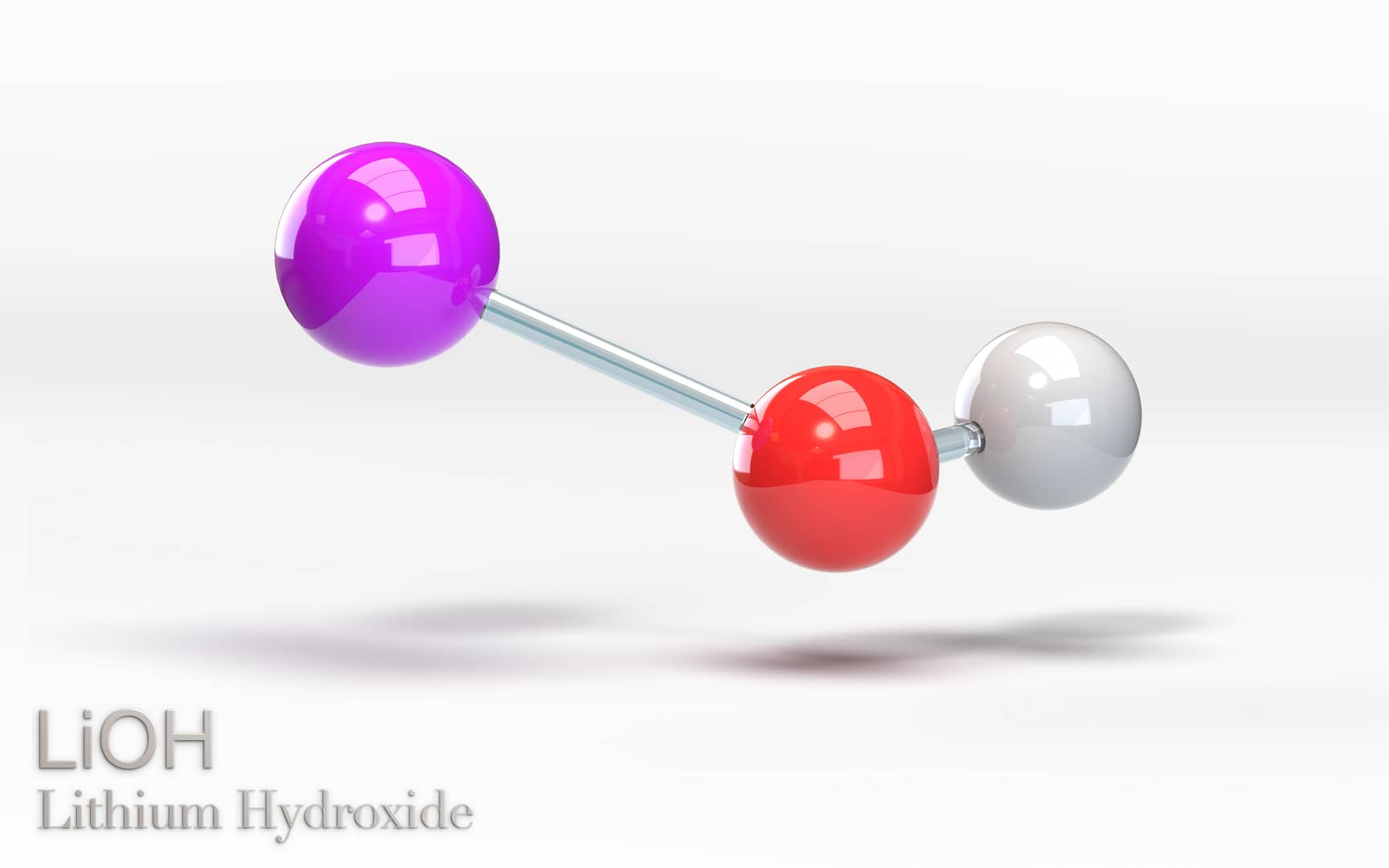

Lithium Hydroxide (LiOH)

Lithium hydroxide (LiOH) is a chemical compound that is composed of one atom of lithium and one molecule of hydroxide. This salt has many different practical uses in industrial and research settings, often being invaluable for its ability to absorb carbon dioxide gas. In basic solution, the compound creates alkali metal ions which act as a pH buffer, helping keep harsh environments regulated.

Lithium Carbonate (Li2CO3)

Lithium Carbonate, or Li2CO3, is a salt of carbonic acid. It has an empirical formula of C6H5Li3O7 and is an odorless, white powder that is soluble in water. Lithium Carbonate has many uses in industry, including glass and ceramics production and lithium batteries.

Lithium Chloride (LiCl)

Lithium chloride is a compound made up of the elements lithium and chlorine. It has the chemical formula LiCl and is an ionic crystal commonly used in experiments and manufacturing processes. Lithium chloride can exist in several different forms, such as tablets, powder, and pellets, which allows it to be used for a variety of purposes, including cooling, fire protection, humidity control, laboratory applications, and even water softening. At room temperature, Lithium Chloride is generally odorless with a color ranging from white to yellowish depending on its purity.

Even though not directly used in Batteries, Lithium Chloride is a very frequent precursor, as it is the form in which Lithium produced from evaporation ponds gets generated.

Other types of Lithium

Aside from the three “main” ones, there are more shapes used, whether along the value chain or dedicated to some particular uses.

Lithium Metal (Li)

Lithium metal is a soft, silver-white metal that belongs to the alkali metal group. It is the lightest of all metals, and it has one of the highest electrochemical potentials. Lithium has a wide range of applications in industries such as electronics, aerospace, energy production, and automotive manufacturing.

Lithium Oxide (Li2O)

Lithium oxide is an inorganic compound composed of lithium and oxygen. It is a strong base and a white crystalline powder. Lithium oxide can be used for several purposes, such as ceramic glaze, fluxes for glass and enamels, additives in catalysis, nuclear medicine, and battery production (indirectly).

Indeed, Lithium Oxide is the one present in spodumene, lepidolite, zinnwaldite, and all other pegmatites that naturally contain Lithium in rock form. That’s the Lithium compound you hear about when mentioning “Lithium content” in minerals (for instance, in SC6, which is a Lithium Oxide content of 6% in Spodumene).

Lithium Bromide (LiBr)

Lithium bromide is an inorganic compound composed of lithium and bromine. It is a white crystalline powder and has various applications, quite similar to all the ones we already listed. When Lithium is obtained from clay – as, for instance, in former volcano deposits – it is quite often an intermediate state fetched along the refining chain.

Lithium Hydroxide Monohydrate (LiOH·H2O)

Lithium hydroxide monohydrate is an inorganic compound composed of lithium, oxygen, and hydrogen. As you would guess from the name, it is a chemical obtained from or before Lithium Hydroxide!

Butyllithium (C4HgLi)

Butyllithium is an organolithium compound composed of lithium and butane. It is a colorless and oily liquid. Butyllithium can also be used to synthesize new compounds or modify existing molecules.

Converting One Type of Lithium to Another: Lithium Carbonate Equivalents

There is a conversion table that enables one to quickly calculate the equivalent of one Lithium in Lithium Carbonate (LCE) – the one usually used as a reference:

| Lithium Type | Lithium Carbonate Equivalent (LCE) |

| Lithium (Li) | 5.323 |

| Lithium Oxide (Li2O) | 2.473 |

| Lithium Hydroxide (LiOH) | 1.544 |

| Lithium Carbonate (Li2CO3) | 1 |

| Lithium Hydroxide Monohydrate (LiOH·H2O) | 0.88 |

| Lithium Chloride (LiCl) | 0.871 |

| Butyllithium (C4HgLi) | 0.576 |

| Lithium Bromide (LiBr) | 0.425 |

How is Lithium Hydroxide used in Batteries?

Lithium hydroxide is one of the base components to produce the batteries’ cathode, as one of the components of the “Lithium-Ion” nexus. It is, for instance, used to produce Lithium cobalt oxide (LiCoO2) or Lithium Iron Phosphate (LiFePO4).

Why Lithium Hydroxide?

First, it is a better source to produce Lithium Nickel Manganese Cobalt oxides (Li-NMC).

Generally speaking, Lithium Hydroxide offers better power density (aka, more battery capacity), longer life cycle (aka, more durability), and enhanced safety features.

What is an alternative to Lithium Hydroxide?

The question is worth asking the other way around: today, Lithium Hydroxide is an alternative to Lithium Carbonate, which has been dominating the Battery space so far.

Is Lithium Hydroxide better than Lithium Carbonate for EV Batteries?

Lithium hydroxide is generally considered to be a better reagent than lithium carbonate for batteries. This is due to its higher purity and active material content, leading to improved electrical performance and a longer battery lifetime.

Lithium hydroxide also has a higher solubility than lithium carbonate, allowing it to react more quickly with the battery’s electrolyte.

And as already alluded to, it has a better power density.

How does the use of Hydroxide and Carbonate evolve over time?

In 2018, Lithium Carbonate had a 73% lion’s share in battery materials, while hydroxide had the remaining 27%. But while Li2CO3 has seen a strong 10% per year growth, the progress of LiOH has rather been explosive, with a 34% growth rate.

As a result, Lithium Hydroxide is expected to take over Carbonate as the most used form of Li in battery applications by 2024.

Of course, this still implies that the battery gigafactories build ad produce as expected and that no major disruption happens on the technological side, but let’s say it is a safe assumption to expect both metal compounds to at least reach a balance in use.

Who makes Lithium Hydroxide?

Today, as outlined in my detailed article on the countries that are rich in lithium, Lithium is extracted in limited parts of the World (mostly China, Australia, Argentina, and Chile) and by a big 4 Lithium Companies (SQM, Albermarle, Ganfeng, Tianqi).

When it comes to LiOH refining, the list even reduces, as this is mostly a mining play today (the road from evaporation ponds to battery materials rather tends to Li2CO3).

As a result, even if it is moving ground with more players and more assets being developed, today the biggest supply of Lithium Hydroxide comes from China and its two historical players: Ganfeng and Tianqi.